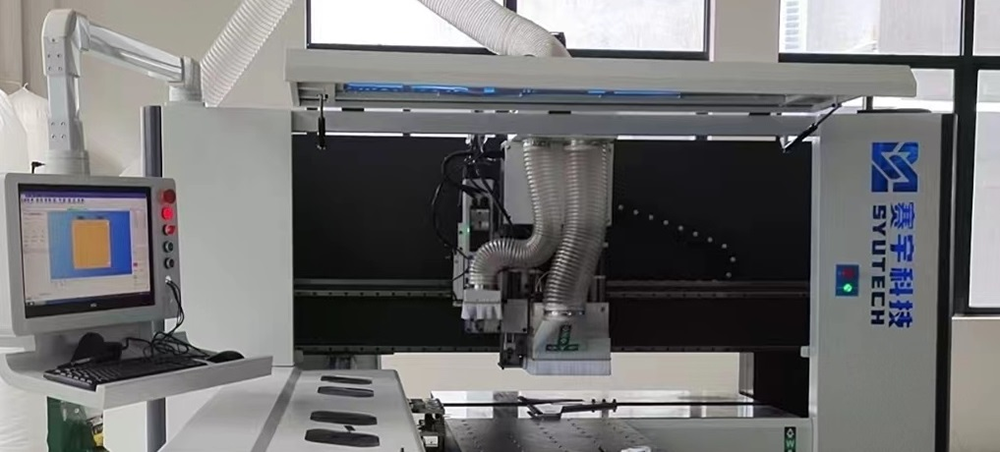

HK612A Six side cnc drilling machine model

Technical parameters

| Model | 612A |

| Length of X-axis clamp guide rail | 5400mm |

| Y-axis stroke | 1200mm |

| X-axis stroke | 150mm |

| Max speed of X-axis | 54000mm/min |

| Max speed of Y-axis | 54000mm/min |

| Max speed of Z-axis | 15000mm/min |

| Min processing size | 70*35mm |

| Max processing size | 2800*1200mm |

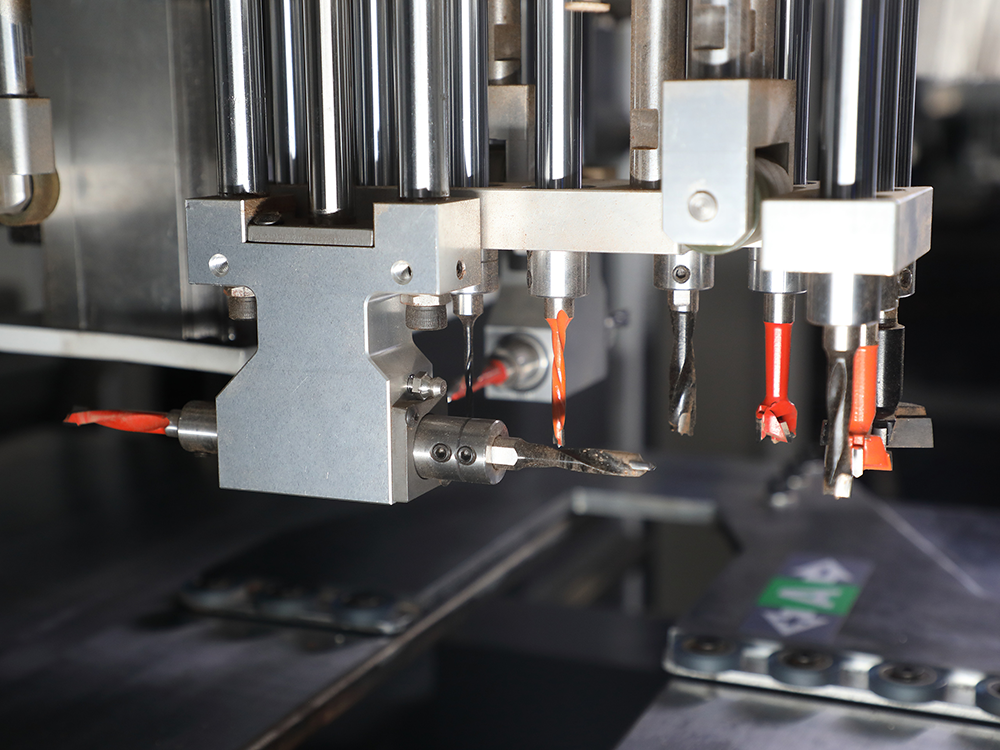

| Number of top drilling tools | Vertical drilling tools 9pcsNow we have update machine,new model is 10PCS |

| Number of top drilling tools | Horizontal drilling tools 4pcs(XY)Now we have update machine,new model is 8pcs |

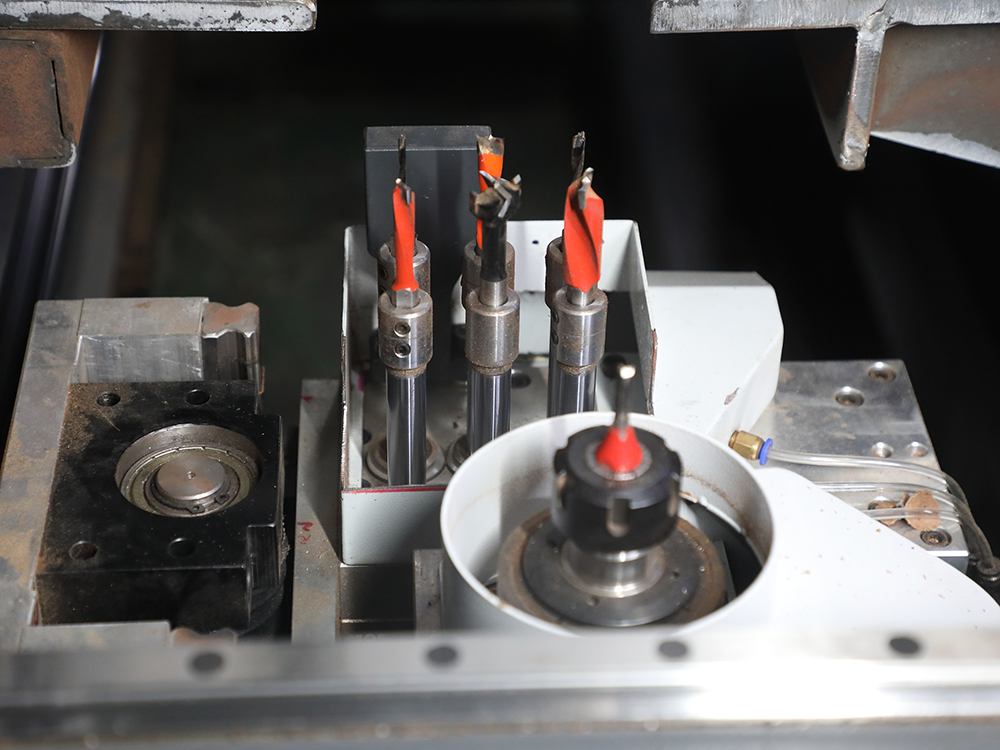

| Number of bottom drilling tools | Vertical drilling tools 6pcsNow we have update machine,new model is 9pcs |

| inverter | inovance inverter380V 4kw |

| Main spindle | HQD 380V 3.5kw |

| Auto | |

| Workpiece thickness | 12-30mm |

| Drilling package brand | Taiwan brand |

| Machine size | 5400*2750*2200mm |

| Machine weight | 3500kg |

CNC six -sided drilling machine can do lamino Machining,Grooving four sides of the board to ensure simple assembly and beautiful appearance hidden connector,Various front groove machining,change the milling cutter according to the groove width, forming groove at one time effectively.

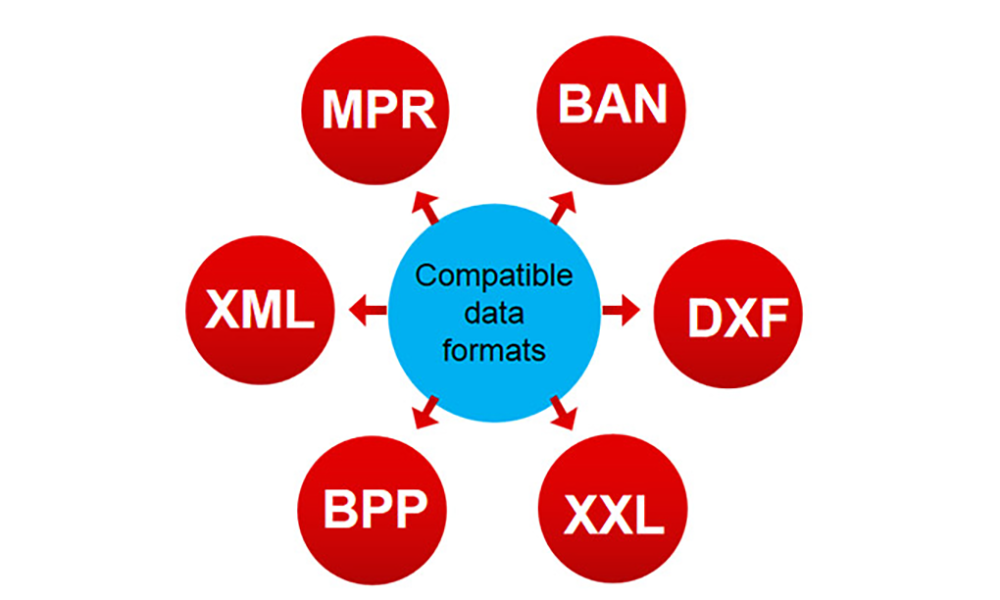

And the six -sided drilling machine can connect a variety of disassembly software, and can directly import open data formats such as DXF, MPR, and XML. The overall operation of the equipment is convenient. It is mainly used for the six -sided drilling holes of the artificial board. hinge holes, pores and semi -pores can be achieved quickly, and the functions are continuously improved and enhanced.

Machine consist of one set drilling bags + one bottom drilling bag(without ATC )

Six-sided processing

One time processing can complete panel 6-side drilling & 2-side grooving, and 4 sides slotting or Lamello works.Minimum processing size for the plate is 70*35mm

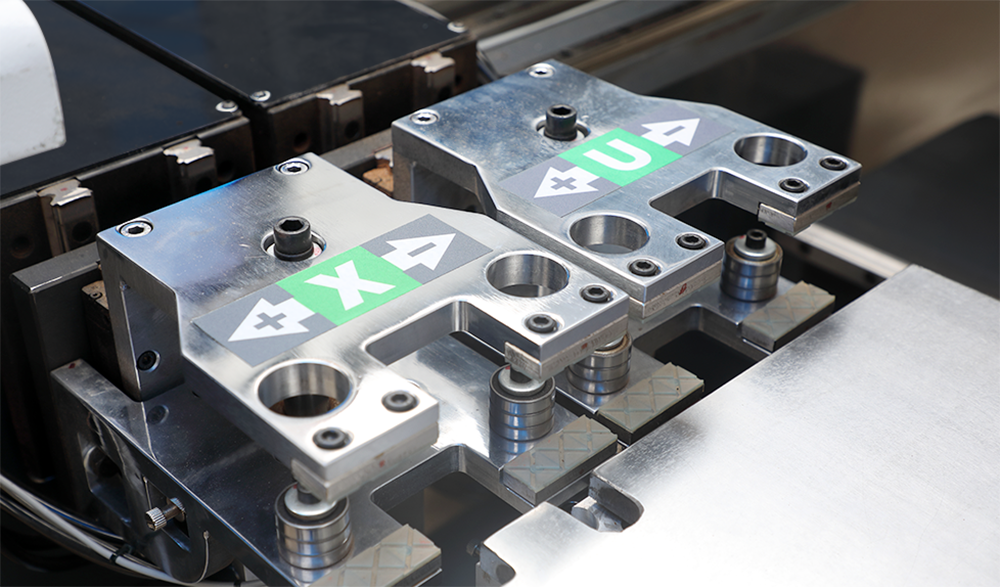

The upper drilling bag:( top vertical drilling 9pcs + top horizontal drilling 6pcs)

Now we have update cnc six side drilling machine,new model is 10PCS+8pcs

The bottom drilling bag:(6pcs)

Now we have update machine,new model is 9PCS

The upper and lower beams adopt an integrated frame structure, which has strong stability and precise processing.

The drilling machine body is very important for the machine stable.

Safety dust shields are installed at the front and rear of the gripper feeding beam to prevent dust from falling into the rack.

It can protect the safety of the operator and avoid being injured when the hand is moved by the clamp.

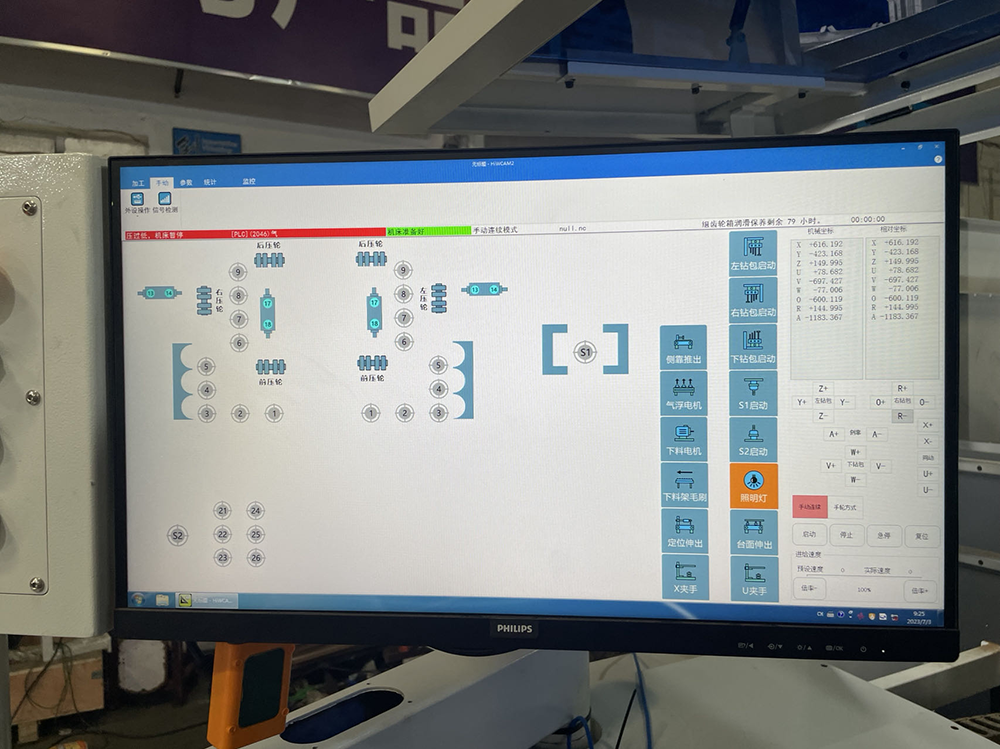

Compatible with Multiple Data Formats

CNC six side drilling machine connect with all kinds data formats,like the MPR,BAN,XML,BPP,XXL,DXF ect.

Machine convenient and efficient operation

Six Sides Slotting and Lamello grooving process

6kw high speed spindle with 5pcs ATC tool changer.

Can process panel 6 sides slotting and lamello grooving production:

19 inch large screen control, Hydemon control system,matched with CAM software

Equipped with CAM software, can be connected to cutting machine/edge banding machine

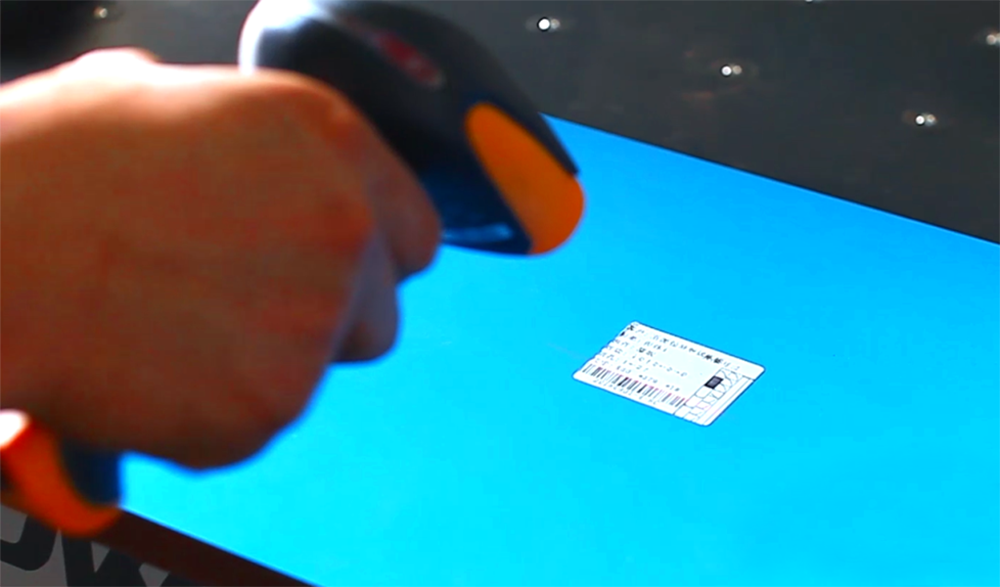

Intelligent industrial control integration, code scanning processing, and high degree of automation.

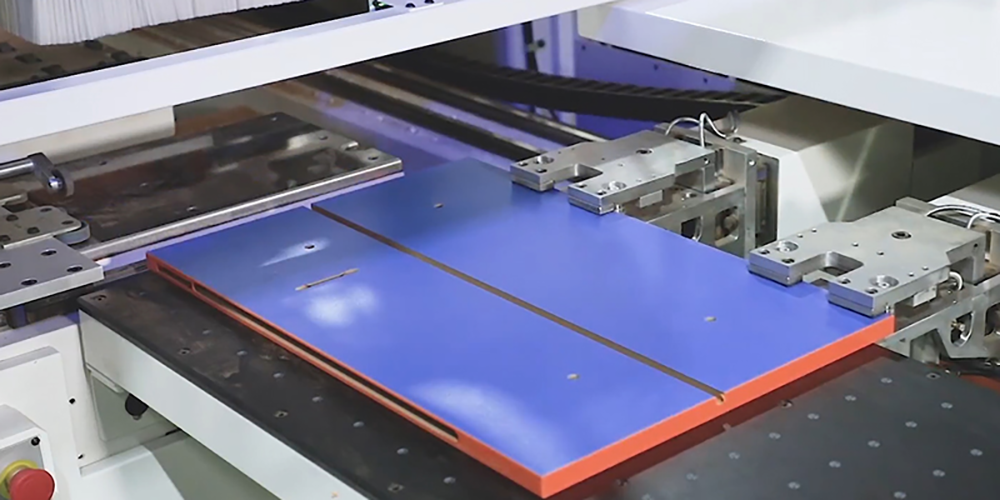

Double clamps

The double gripper mechanism is adopted to automatically control the feeding and positioning of the panel according to the computer drilling program.

Widened air flotation platform 2000*600mm widened air flotation platform

Effectively protects the surface of the sheet from scratching

Optional loading and unloading modes: front in/front out or rear out Can be connected to a rotating line.

Advantage

High efficiency and high productivity:

100 sheets can be processed in 8 hours per day with cnc six-sided boring machine