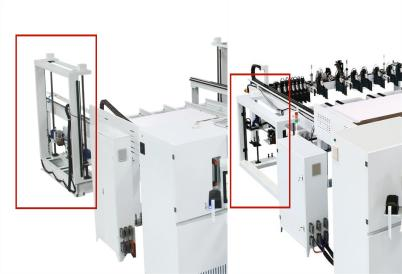

Rear loading double push beam CNC computer saw

Functions and features

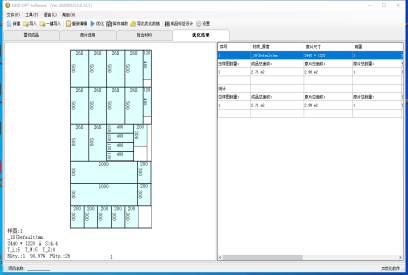

Processing software description (optional)

It retains the flexibility of random manual arrangement of cutting data of traditional electronic saws, and expands the features of intelligent data import, wireless remote control start and stop operation, remote monitoring, etc., and adds practical functions such as order design, order splitting optimization, surplus material management, layout optimization, barcode printing, etc. At the same time, it is open to all software ports, such as Yuan Fang, Hua Guang, CV, 1010, Wei Lun, Hai Xun, Sanweijia, Yunxi, Shangchuan and other design software, and supports Microsoft Excel handmade material list, with powerful optimization layout programming function, and can construct real-life operation to simulate real problems. When workers operate the equipment, they only need to place the workpiece and cut the size data according to the prompts on the computer interface. It is refreshed by computer intelligence (scanning code) to achieve one-click operation, and generally only needs 2 hours of training to start work.

Accessories Brand

Configuration List

| Serial No. |

Structure Name |

Specific instructions |

Function |

|

1 |

Body structure |

Table: The table is made of 25mm steel plate and square tube welded together.

Machine body: Square tube reinforcement welding, zero critical temperature annealing。 |

It ensures the long-term sawing accuracy of the machine and also ensures that the machine body will never deform and is durable. |

|

2 |

Electrical structure |

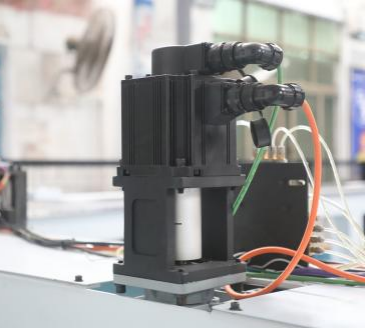

Pneumatic: Saw blade lifting cylinder diameter 80*125mm | The pressure is greater and multiple boards are less likely to slide. |

| Large saw motor: 16.5kw

Small saw motor: 2.2kw Saw traction (servo) motor: 2.0KW. |

High power, sufficient power |

||

|

Electrical appliances: Taiwan Yonghong PLC programming controller/touch screen; imported Schneider contactors, INVT servo motors, inverters; E-day pneumatic components, which extend the service life of the machine |

Electrical stability extends the service life of the machine |

||

| Trolley running limit device: magnetic sensor control | It replaces the previous rod-type travel switch which is easy to get stuck due to dust. | ||

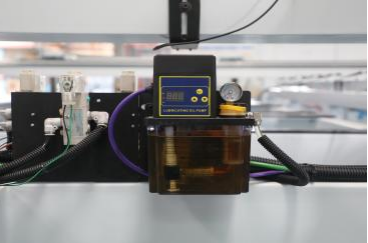

| Air pressure: The air pressure of this equipment should be maintained at 0.6-0.8MPA during use |

Higher pressure, stable air source, guaranteed cutting accuracy |

||

| Voltage: This equipment uses 380 volts 3 phase 50 Hz | According to customer needs, a transformer can be added to change the corresponding volts

(optional) |

||

|

3 |

Safety structure |

Adopt Taiwan imported aluminum bar anti-hand pressure device to ensure personnel safety |

Ensure the safety of the production process and reduce potential safety hazards |

|

4 |

Sub-station structure |

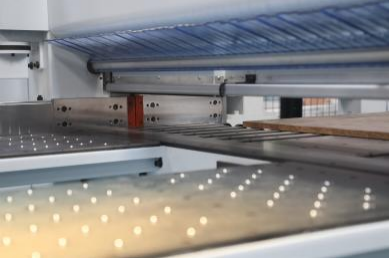

Air-floating steel ball table, high-pressure fan provides buoyancy |

The panels are easy to move, easy to load and unload, and protect the panel surface from scratches |

|

5 |

Transmission structure |

Positioning guide rail and saw blade lifting guide rail device: using Taiwan Yinchuang Technology, square steel belt linear precision guide rail |

Durable and wear-resistant, not easy to deform, not easy to hide dust and cause the saw to get stuck |

|

Rack traction drive |

The pulling force is more uniform and the strength is more stable |

||

|

The main saw uses Taiwan Samsung multi-groove belts, and the small saw V-belts use imported belts. |

The main saw multi-groove belt imported from Taiwan is 20 times more durable than the V-belt |

||

|

6 |

Saw shaft structure |

The large saw uses a φ360*φ75*4.0mm alloy saw blade. The small saw uses a φ180*φ50*3.8/4.8 alloy saw blade. |

(Optional according to customer needs) |

|

7 |

Dust-proof structure |

The up-and-down dust curtain makes the working environment cleaner and the sawing accuracy higher |

The entire cutting workshop is free of dust, which reduces harm to people, and the production environment is cleaner and less noisy. |

|

8 |

Control Structure |

19-inch touch/button integrated computer screen, the cabinet can be rotated 180º |

Suitable for operation at different angles, easy to use. |

Technical Parameters

|

Product Name/Model |

Double push beam rear loading MA-KS838 |

|

Main saw power |

16.5kw(Optional18.5kw) |

|

Vice saw motor power |

2.2kw |

|

Maximum sawing width |

3800mm |

|

Maximum stacking thickness |

100mm(Optional120mm) |

|

Minimum cross-cutting board size |

5mm |

|

Minimum board size for vertical cutting |

40mm |

|

Positioning method |

automatic |

|

Servo positioning accuracy |

0.02mm |

|

Sawing accuracy |

±0.1mm |

|

Main saw blade outer diameter |

360mm-400mm |

|

Main saw blade inner diameter |

75mm |

|

Main saw speed |

4800r/min |

|

Traction motor power (servo) |

2.0kw |

|

Robot motor power (servo) |

2.0kw |

|

Cutting speed |

0-100 m/min |

|

Return speed |

120 m/min |

|

Lifting platform power |

3kw |

|

High pressure blower |

4kw 2.2kw(Two) |

|

Side lean |

0.55kw |

|

Air pressure |

0.6-0.8mpa |

|

Air flotation table specifications |

1750*540mm (Four) |

|

Industrial control screen |

19寸 |

|

Total Power |

32kw(Optional34kw) |

|

Machine tool size |

9240*6270*2000mm |

|

Lifting platform size |

5680*2200*1200mm |