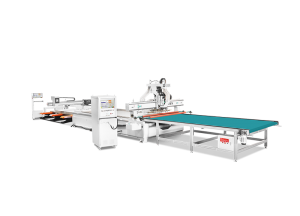

One-to-two connection for cutting machine Automatic tool change

One-to-two connection for cutting machine Automatic tool change

Used for cutting, milling and drilling (optional) of various furniture and wood products to achieve automated production and reduce manual dependence. Especially suitable for the processing of customized furniture parts, effectively improving production efficiency and product accuracy. Suitable for processing materials: fiberboard, particleboard, melamine board, solid wood board, gypsum board, cardboard, plexiglass board

Machine Function

Automatic feeding platform

The lifting platform is automatically loaded, equipped with double suction cups with strong adsorption force, and the loading is more stable

Larger table design

One-time positioning and fast cutting are achieved. At the same time, the thickened frame is used, which is stable, durable and not easy to deform.

Double limit

Loading on the lifting platform, cylinder limit + photoelectric limit sensing lifting position, double limit protection, safe and reliable

Automatic labeling

Honeywell label printer, prints clear labels 90° intelligent rotating labeling automatically adjusts the direction according to the plate, fast labeling, simple and fast, stable and reliable

Complete technology

Straight-row tool magazine, 12 knives can be switched freely, with complete processes, meeting invisible parts/three-in-one/Lamino/Mudeyi and other processes

Continuous processing

The cylinder pushes the material, and the material is unloaded and loaded at the same time, labeling and cutting do not affect each other, realizing uninterrupted processing, reducing the picking of plates, and improving processing efficiency

Powerful function

Human-machine integration, Baoyuan control system intelligent operation, simple and easy to understand, automatic layout can be sorted according to orders, automatic processing

Powerful cutting

HQD air-cooled high-speed spindle motor, fast automatic tool change, low noise and stability, strong cutting force, smooth cutting surface, suitable for cutting a variety of raw materials

Automatic unloading

Fully automatic unloading device replaces manual unloading, which is convenient and fast, increasing production and improving efficiency

Core Advantages

Various processes

It realizes various processing techniques such as drilling, grooving, special-shaped cutting, carving, milling, hollowing, etc., and the cabinets, door panels and cut boards will not have broken edges or burrs.

Excellent performance

Electrical components such as Huichuan servo motors, Delixi Electric, and Japan Shinpo reducers have excellent performance, are resistant to strong interference, and ensure high-precision processing effects.

Save labor

Automatic loading and unloading, fast cutting, the whole process can be completed by one person, realizing automated processing, saving labor costs, and reducing the difficulty and error rate of manual operation.

Strong compatibility

It can be connected to all order splitting software on the market, optimize layout, perform flexible processing, improve sheet material utilization and reduce waste.

Finished product display

Application

Particleboard, fiberboard, multilayer board, ecological board, oak board, finger-jointed board, straw board, solid wood board, PVC board, aluminum honeycomb board, etc.

Technical parameters

|

Workbench size |

2500x1250 mm |

Spindle power |

9kw |

|

Spindle speed |

24000r/min |

Air source pressure |

0.6~0.8MPa |

|

Vacuum hose size |

150mm、150mm |

Total Power |

23.7KW |

Customer Case

Exhivition

Loading and shipping