01 Automated production

The processes of cutting, edge banding, drilling, grooving, etc. are integrated to realize automated production, reduce manual operations, lower production costs and improve precision.

02 Increase production capacity

The connection of cutting machine + edge banding machine + six-sided drill can reduce the pause and waiting time in the production process, improve the continuity and stability of the production line, save labor and increase production capacity.

03 Good flexibility

According to different production needs, the parameters and processes of each process can be flexibly adjusted to meet diverse production needs.

04 Save board materials

By optimizing layout and cutting methods, the utilization rate of sheets can be improved, waste can be reduced, and production costs can be lowered.

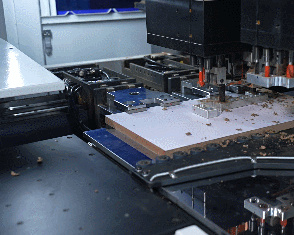

HK-6

Multi-functional,high efficiency;province of labor,less waste!

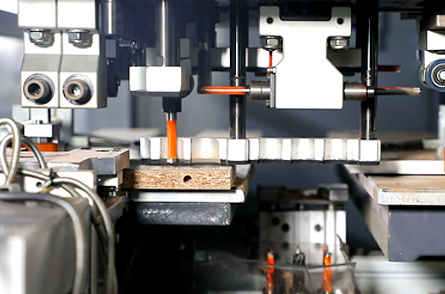

12pcs tool change,complete technology,multi-tool free switch,continuous production without stopping.

12 in-line knife changers, complete technology, multiple knives can be switched freely, and continuous production without stopping.

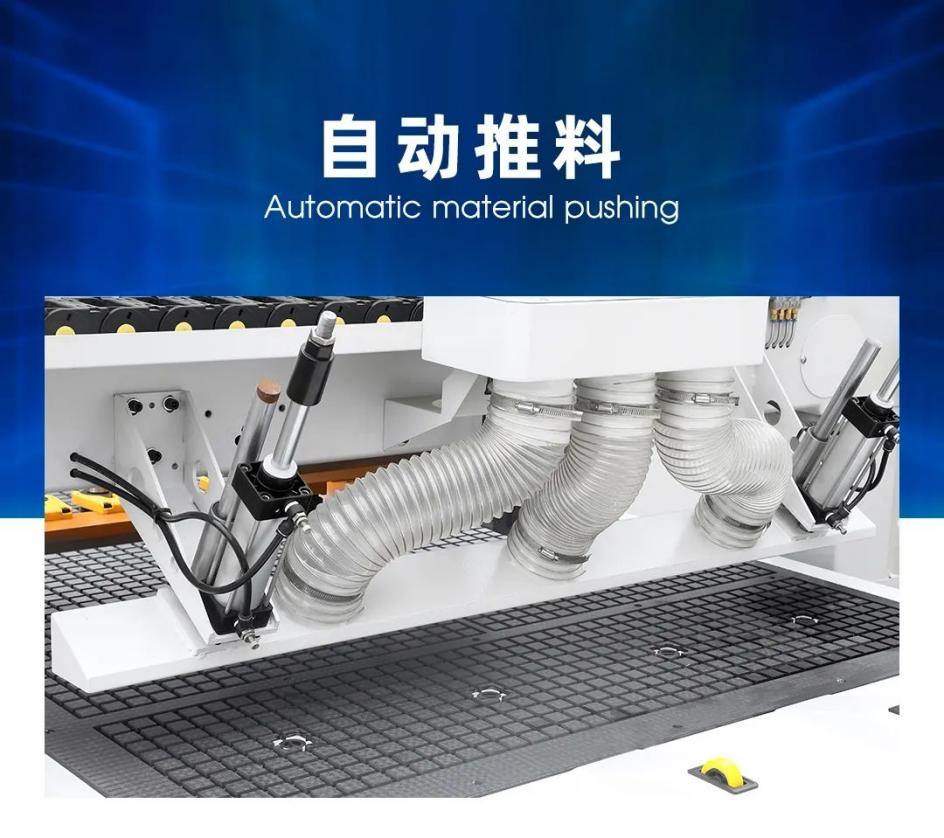

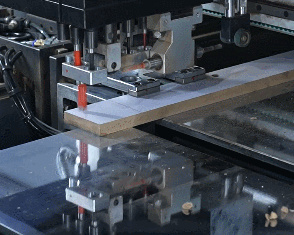

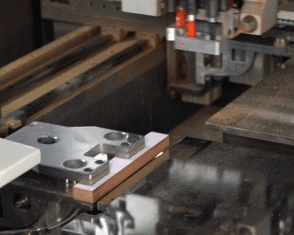

Cylinder pusher, added welding guide column, more stable pushing, one-key dust removal, and rubber wheel to assist loading.

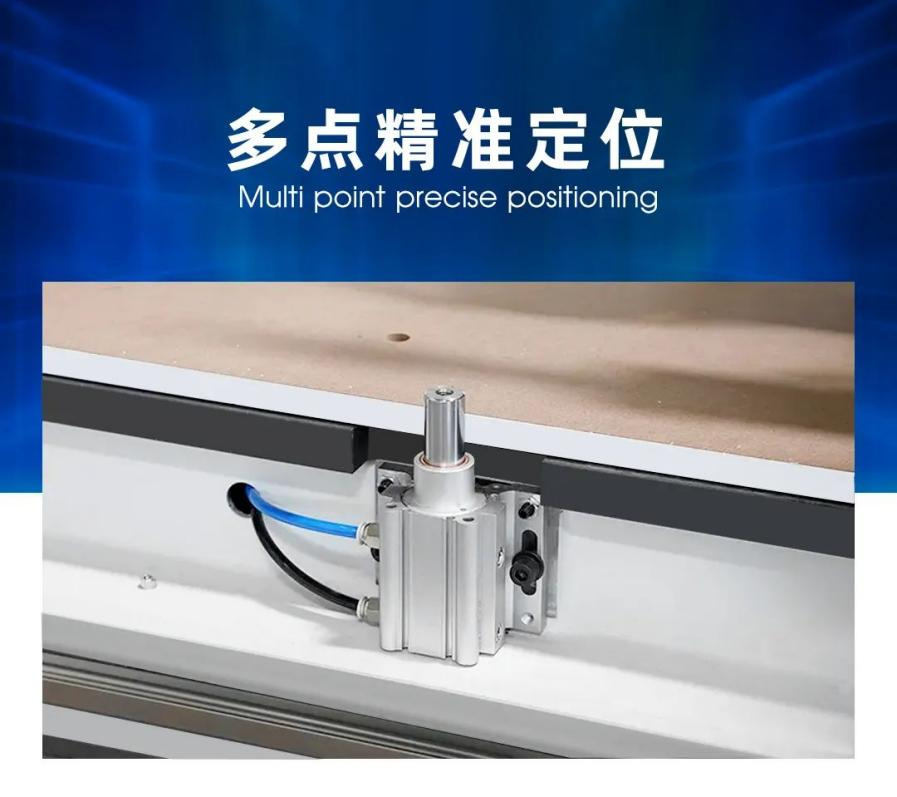

Repeated positioning structure, 3+2+2 automatic positioning cylinder, accuracy controlled within ±0.03mm

Adopt Inovance servo motor, strong control performance, high precision, full set of Inovance configuration, Inovance inverter + drive

Taiwan LNC control system, intelligent control panel, easy to operate

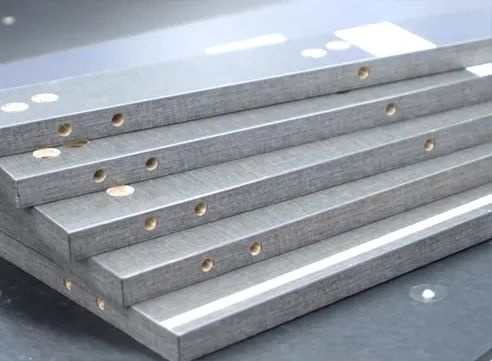

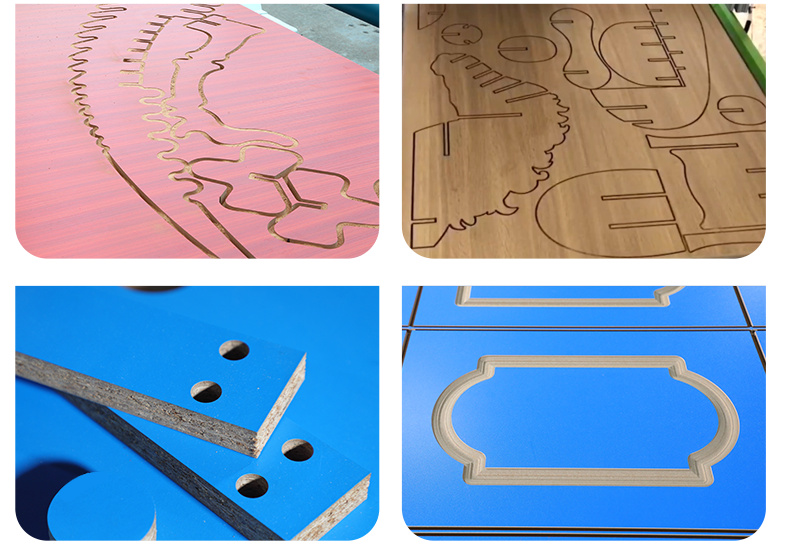

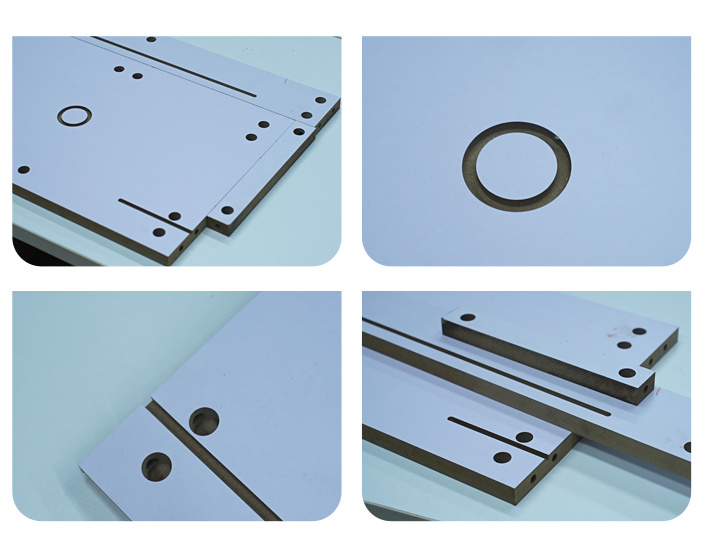

Finished product display

HK-968-V1

PUR heavy-duty fully automatic high-speed edge banding machine

Cabinet doors and cabinets, switch with one click!

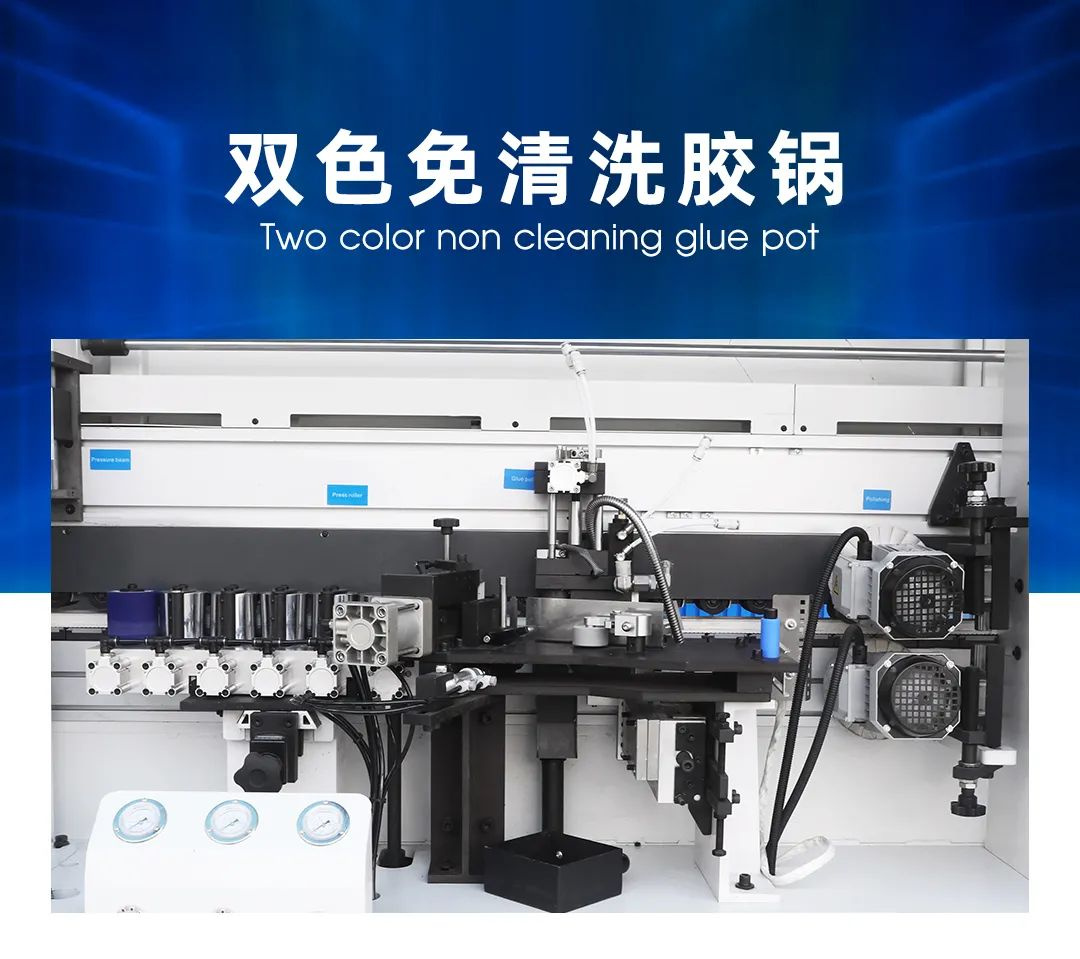

Two-color no-clean glue pot,Save time, effort and efficiency,Save glue and avoid waste,full functioning,Two sets of scraping edges,Convenient cabinet door and cabinet edge banding,One-click switch

The two-color PUR no-clean glue pot is easy, simple and quick to clean. It can switch between two colors of glue to meet different needs, discharge glue evenly, ensure high-quality edge banding effect while reducing the amount of excess glue.

The operation is simple and convenient, with aluminum and wood edge banding, dual-purpose machine, large and bold display screen, intelligent control, which enables you to fully see the machine operation process, more stable transmission and higher efficiency.

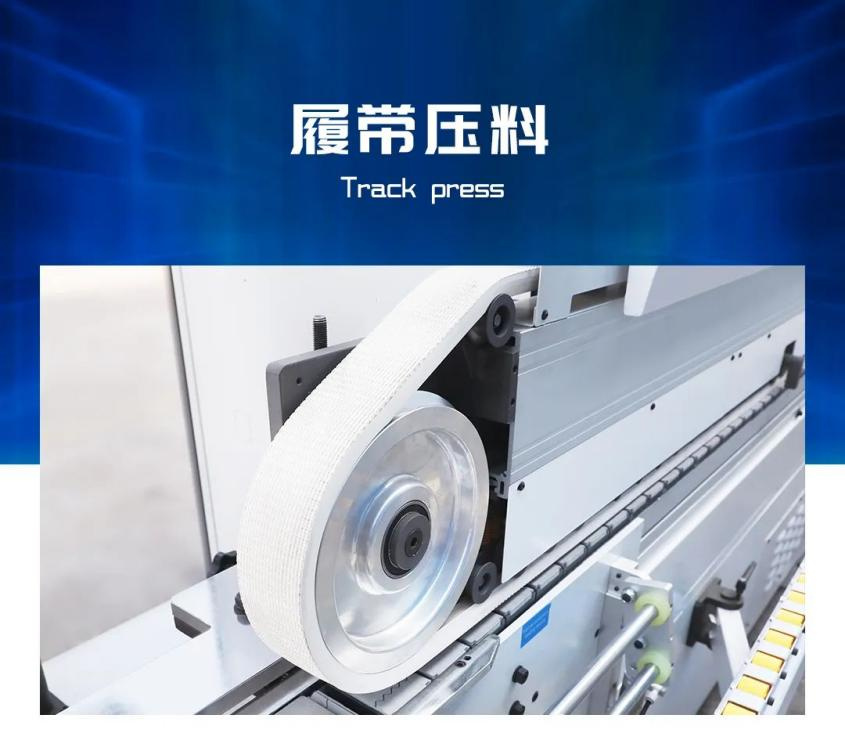

Features such as high transmission speed, smooth and automatic board movement, strong coverage, and stability without board running make the pressing more stable, ensuring the quality and stability of the edge banding process.

Finished product display

HK-612B-C

Double drill package CNC six-sided drilling machine

Air-floating table with built-in tool magazine

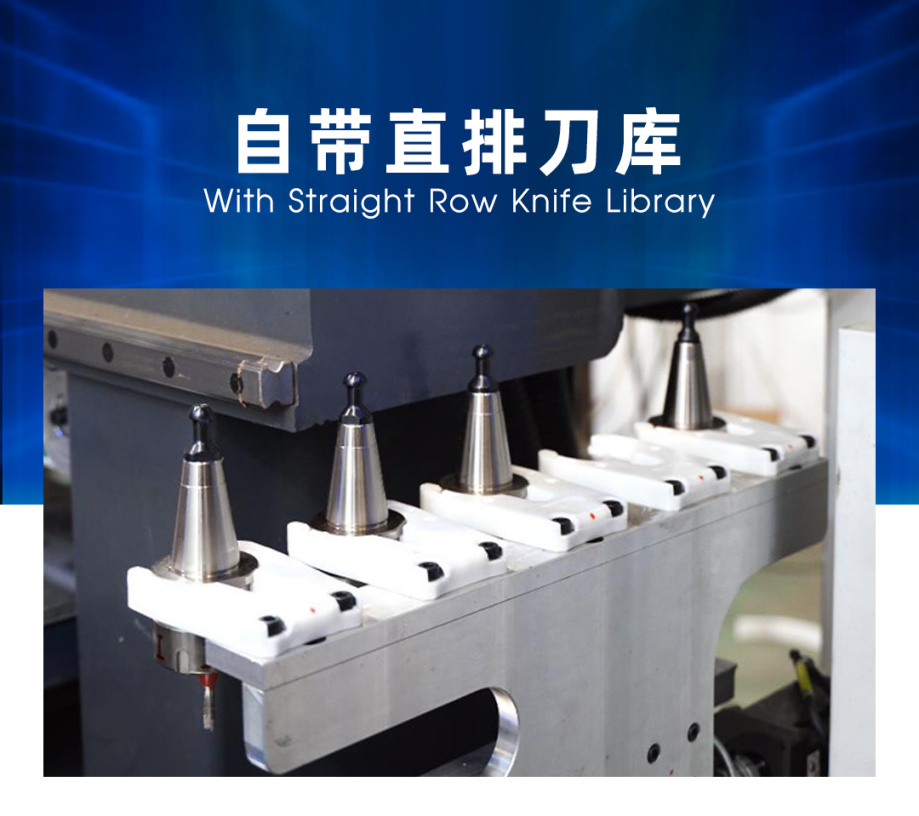

5-tool straight-row tool magazine, automatic tool change, continuous processing, meeting various processing needs

Process six sides at a time, including drilling, slotting, milling and cutting, to achieve diversified processing

Taiwan protean drilling bag, the interior of the drilling package is mainly made of imported accessories, stable processing, two upper drilling packages + 1 lower drilling package (with 6 drill bits), servo motor + screw drive

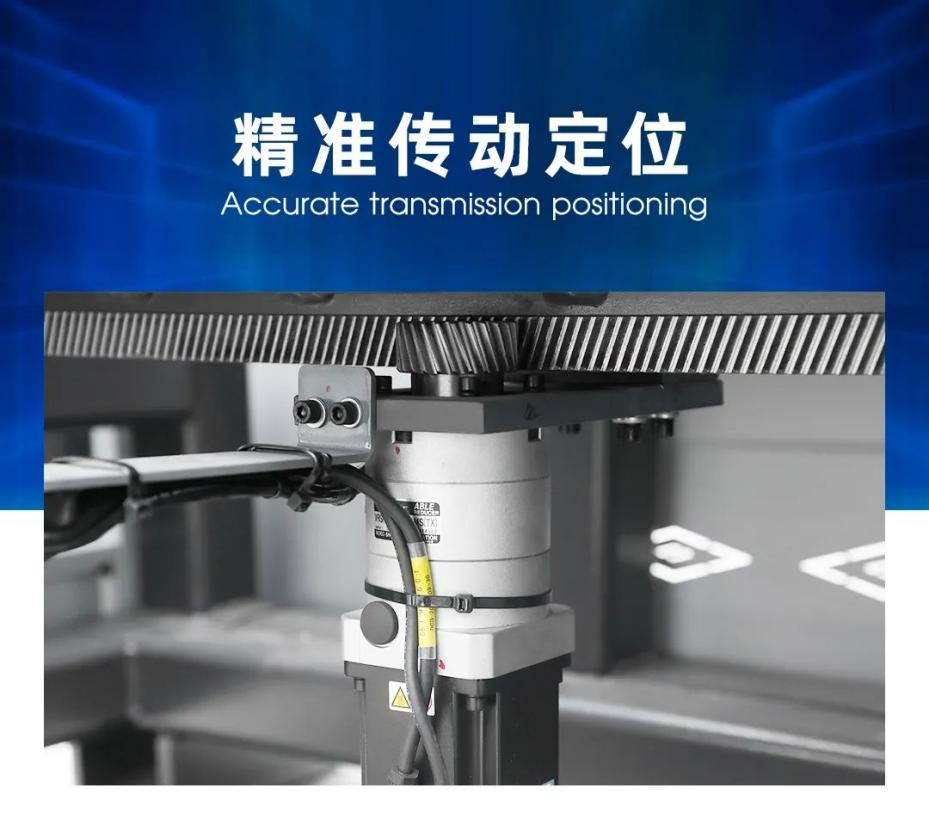

30mm diameter screw rod + German 2.0 die high-precision helical gear and large gear, good rigidity, more accurate, gapless copper guide sleeve positioning cylinder, lower beam double guide rail control is more stable

5-tool straight-row tool magazine, automatic tool change, continuous processing, meeting various processing needs

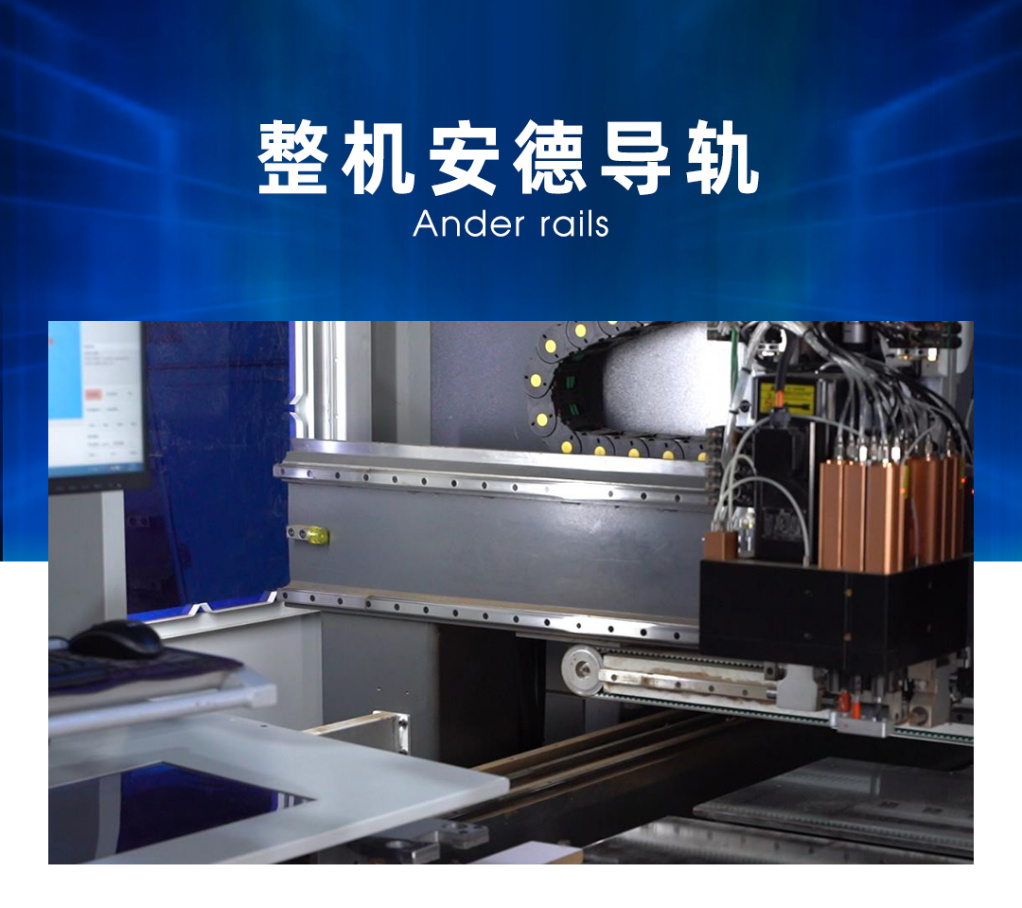

The six-sided drilling machine is equipped with Ande guide rails as standard, with strong load capacity and smooth operation

01 core advantages

Six-sided efficient processing

Basic functions such as drilling, milling, grooving, etc., continuous and efficient processing, high efficiency and high production capacity

02

Tool magazine + tool changing spindle

Automatic spindle tool change and five-tool magazine in a straight row to meet customers' different flexible processing needs

03

Invisible parts processing

The tool magazine can be equipped with saw blades, straight knives, milling cutters, lamino knives, T-type knives, etc., to process lamino, light wire trough, side trough, straightener, handle-free and other processes to solve the problem of slotting invisible parts

04

One person, one machine, multiple uses

A variety of discharge methods are available, including forward discharge, forward discharge, side discharge, and online operation. Only one person is needed to complete the processing of one machine, which is powerful and saves labor.

Finished product display

One-stop service, worry-free throughout the process

Whole-plant supporting, all-round creation

1) Customized solution: Provide whole-plant solution according to customer budget to meet production needs.

2) Assist in site selection: Provide customer production plant site selection service in the early stage.

3) Planning layout: Circuit and gas path planning and determine the wiring and placement of production line machines.

Equipment settled in, production started

1) The whole plant equipment is in place at one time, and the production line is delivered in full.

2) Professional installation and commissioning team provides on-site service, and the machine is tested and adjusted in one step.

3) Operation training is provided to ensure that employees are proficient in using the equipment.

4) Delivery is completed in 2-3 days, production is quickly put into production, cycle is shortened, and efficiency is improved.

After-sales guarantee, peace of mind

1) Establish file management to facilitate after-sales service.

2) Dedicated personnel to connect with after-sales, online communication at any time, and timely arrival 24 hours a day.

Saiyu Technology provides whole-plant production line supporting services

Applicable to whole-house customization, panel furniture,

whole-house decoration, office furniture and other production and processing

Successfully implemented multiple sets of mature production line solutions at home and abroad

Provide customers with excellent productivity and quality assurance

If you have any specific questions about this information, please feel free to ask!

We are specialized in producing all kinds woodworking machine,cnc six side drilling machine,computer panel saw,nesting cnc router,edge banding machine,table saw,drilling machine,etc.

Contact:

Tel/whatsapp/wechat:+8615019677504/+8613929919431

Post time: Jun-21-2024