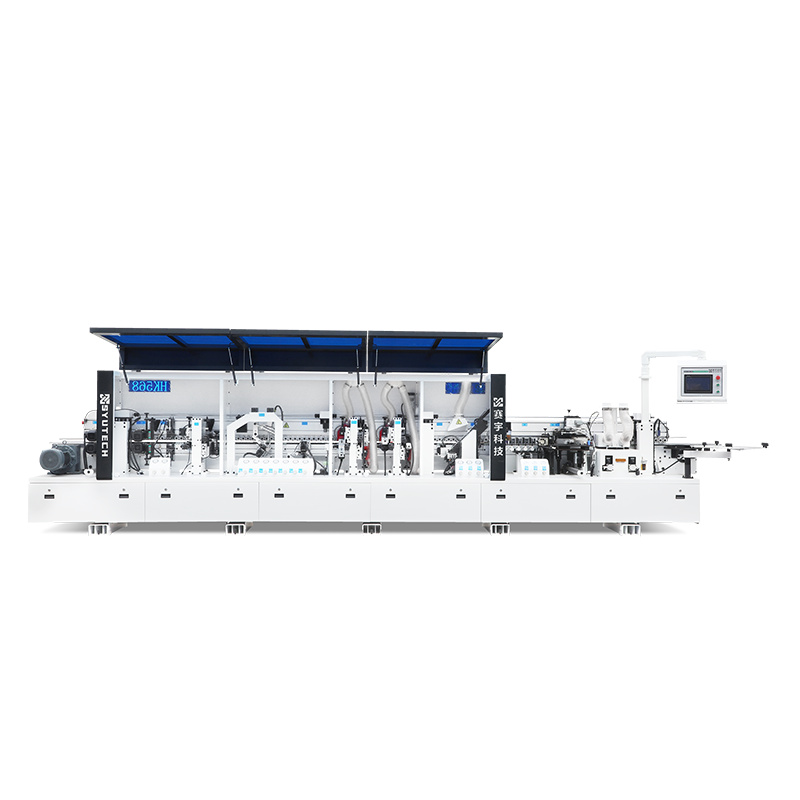

The fully automatic edge banding machine is mainly used for the production of panel furniture and wooden doors, and has a very important effect on various wooden furniture, wooden doors and other products. Functions include pre-milling, gluing, end trimming, rough trimming, fine trimming, scraping, corner rounding, polishing, grooving, etc. It is a good helper for the production of wooden products.

Pre-milling :Use double milling cutters to retouch the ripple marks, burrs or non-vertical phenomena caused by panel sawing and cutting saw processing to achieve better edge sealing effects. The bonding between the edge strip and the board becomes tighter and the integrity and beauty are better.

Gluing :Through a special structure, the edge-banding board and edge-banding material are evenly coated with glue on both sides, ensuring a stronger adhesion.。

End trimming :Through precise linear guide motion, the automatic tracking of the model and the rapid cutting structure of high-frequency and high-speed motors are used to ensure that the cutting surface is flat and smooth.

Rough trimming、fine trimming:They all use model automatic tracking and high-frequency high-speed motor structure to ensure that the upper and lower parts of the trimmed plate are flat and smooth. It is used to repair and remove the remaining edge banding material on the upper and lower sides of the edge banding strip of the processed board. The rough trimming knife is a flat knife. In order to process the remaining parts of the sealing veneer. Because when sealing the veneer, you cannot directly use the R-shaped finishing knife. The veneer is generally 0.4mm thick. If you use the finishing knife directly, it will easily cause cracks. In addition, rough repair can also be used to seal PVC and acrylic. Click the document link to check more information. Click the document link to check more information about the first flat repair process. The finishing knife is an R-shaped knife. It is mainly used for PVC and acrylic edge strips of panel furniture. Edge strips with a thickness of 0.8mm or more are preferred.

Corner rounding :The upper and lower rounding equipment can make the end face of the plate smoother and more beautiful

Scraping :It is used to eliminate the ripple marks caused by the non-linear cutting process of trimming, making the upper and lower parts of the plate smoother and neater;

Polishing:Use a cotton polishing wheel to clean up the processed plate and polish it to make the edge end surface smoother.

Grooving:It is used for direct grooving of wardrobe side panels, bottom panels, etc., which reduces the process of panel sawing and is more convenient and faster; it can also be used for grooving aluminum edging of door panels.

Maintenance precautions:

1. First of all, it is necessary to perform regular maintenance on the edge banding machine. Generally, the maintenance cycle of the edge banding machine is about 20 days. It should be noted that during the maintenance process, the wear and tear of bearings, gears, eccentric bodies and other parts should be recorded in detail(Edge Banding Machinery).

2. The edge banding machine (Wood Edge Banding Machine)must be cleaned to a certain extent after the work is completed to clean up some impurities generated during the working process to avoid clogging the next time it is used.

3. Regularly perform lubrication system treatment on the edge banding machine. When selecting lubricating oil, pay attention to choosing good quality.

4. After the edge banding machine has been used for a period of time, all parts of the edge banding machine should be inspected. If there is any slack, it should be dealt with in time. The protection and maintenance of the edge banding machine plays a vital role in the use of the edge banding machine. Therefore, when using the edge banding machine daily, do not forget to perform regular maintenance on the edge banding machine.

If you have any specific questions about this information, please feel free to ask!

We are specialized in producing all kinds woodworking machine,cnc six side drilling machine,computer panel saw,nesting cnc router,edge banding machine,table saw,drilling machine,etc.

Tel/whatsapp/wechat:+8615019677504/+8613929919431

Email:zywoodmachine@163.com/vanessa293199@139.com

Post time: Mar-27-2024