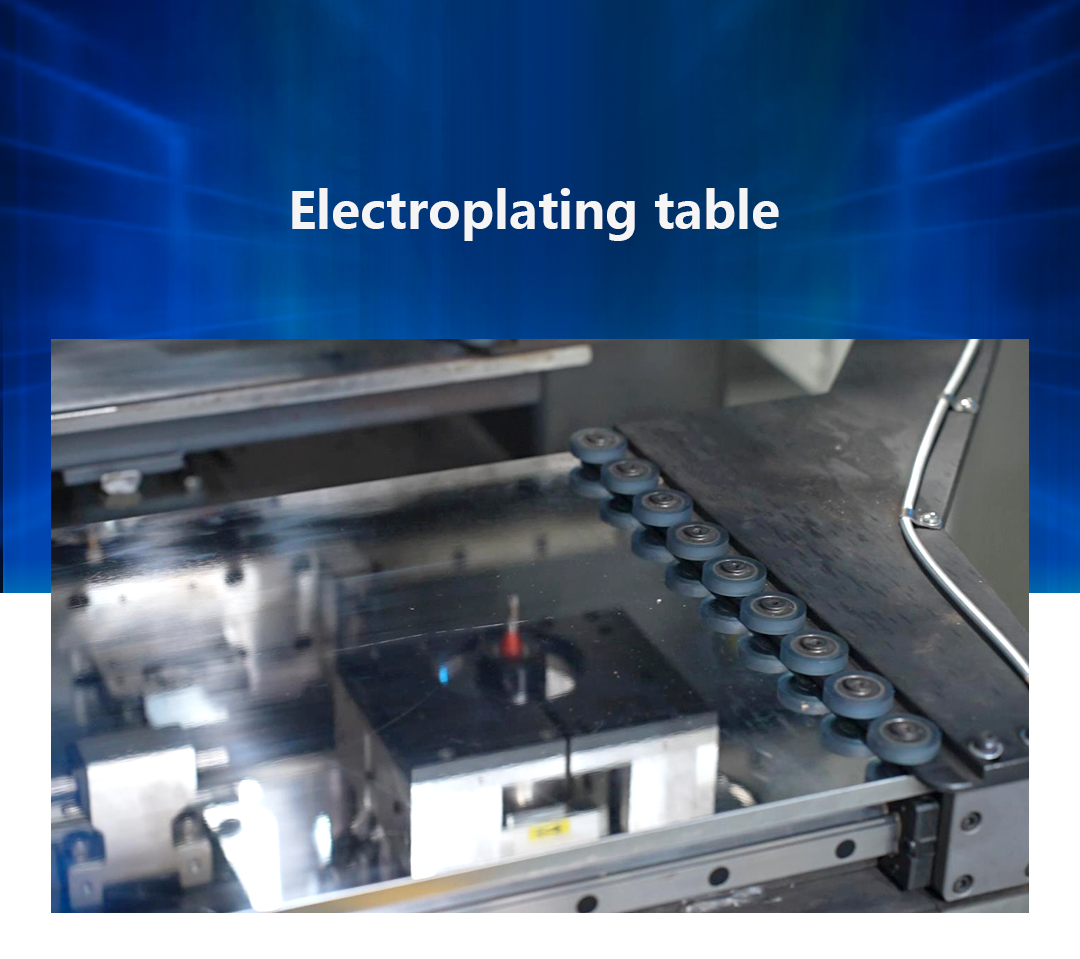

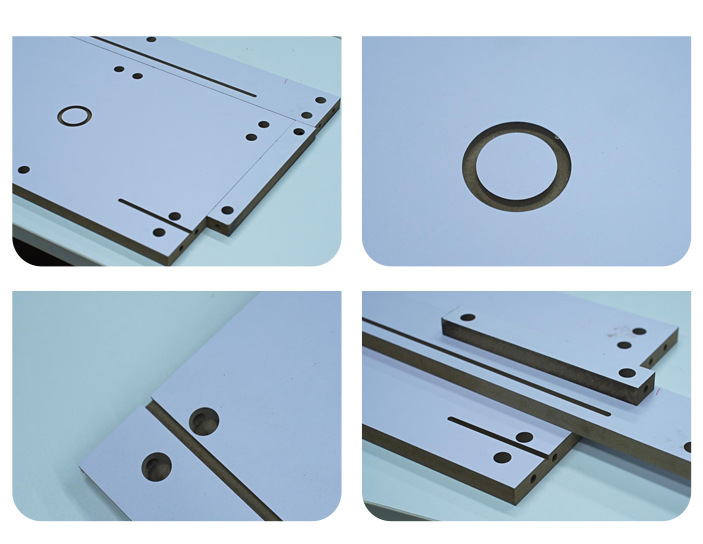

Electroplated processing table, the surface is hardened, with high precision, smoothness, flatness and hardness, will not scratch the board, not easy to deform and more durable

HQD drill bag, two upper drill bags + one lower drill bag,

Precision ±0.15mm

Adopting servo motor control, the drill bag comes with a pressure wheel and pressure plate,

More stable processing

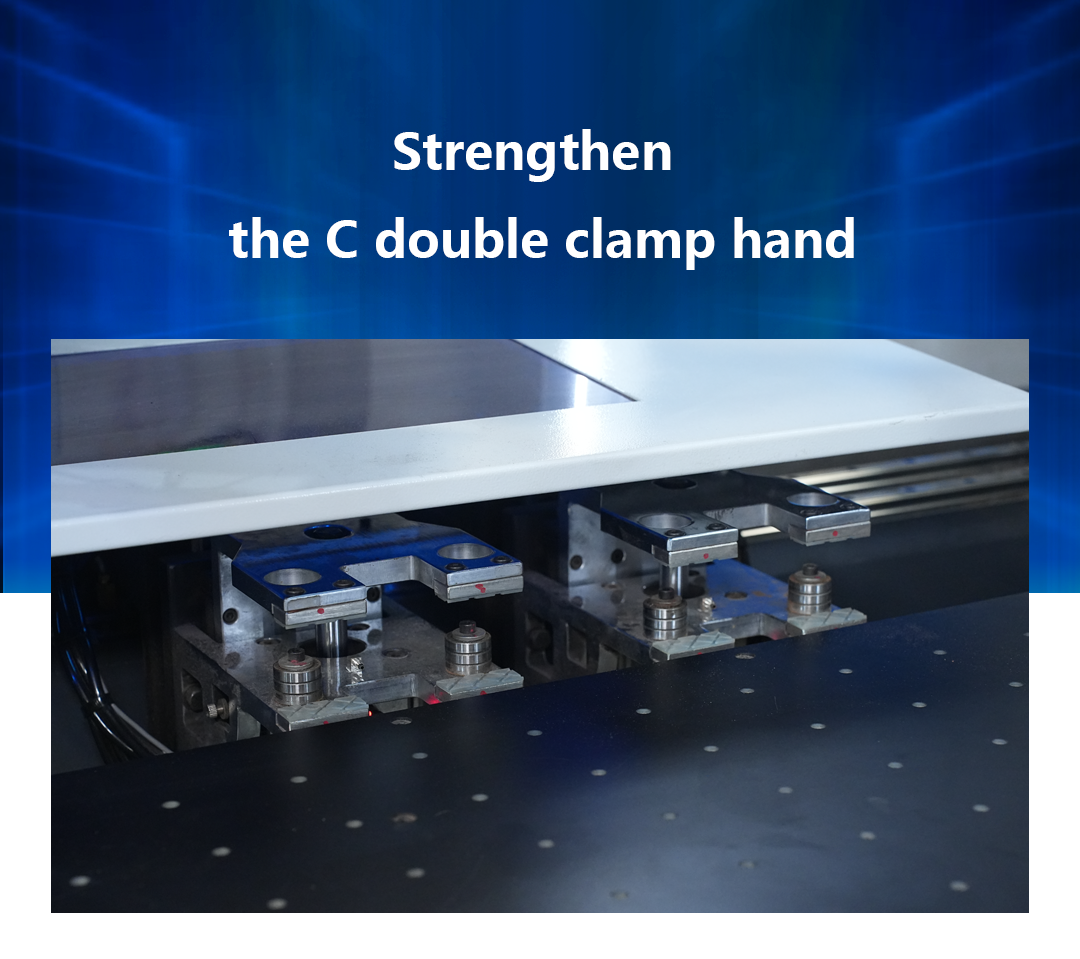

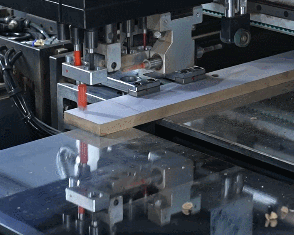

Reinforced C-type double clamps, can process narrow boards with a minimum width of 30m

Clamp groove design, can flexibly avoid, convenient for processing extreme holes

The six-sided drilling machine is equipped with Ande guide rails as standard, with strong load capacity and smooth operation

Grinding-grade gear racks, low noise and torque Stronger, more stable

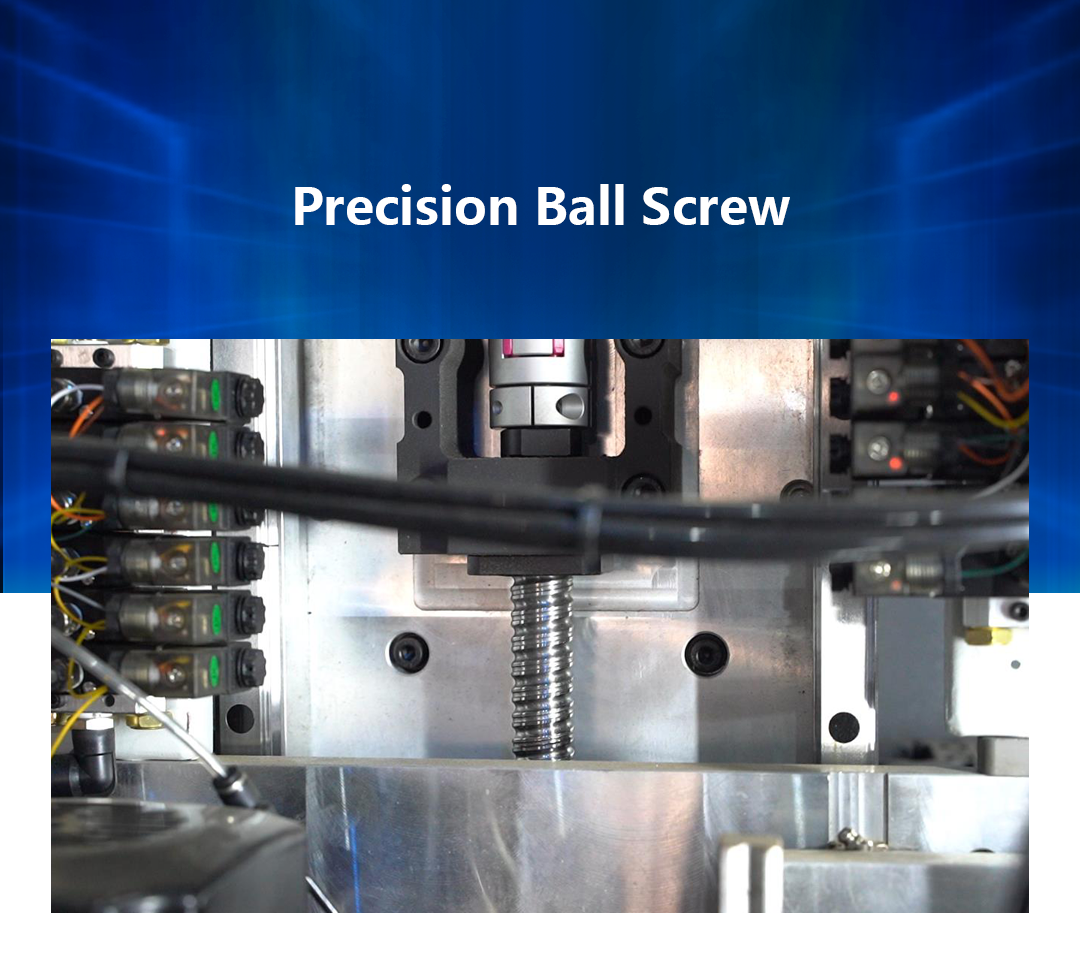

High-precision ball screw, high processing accuracy, low maintenance cost

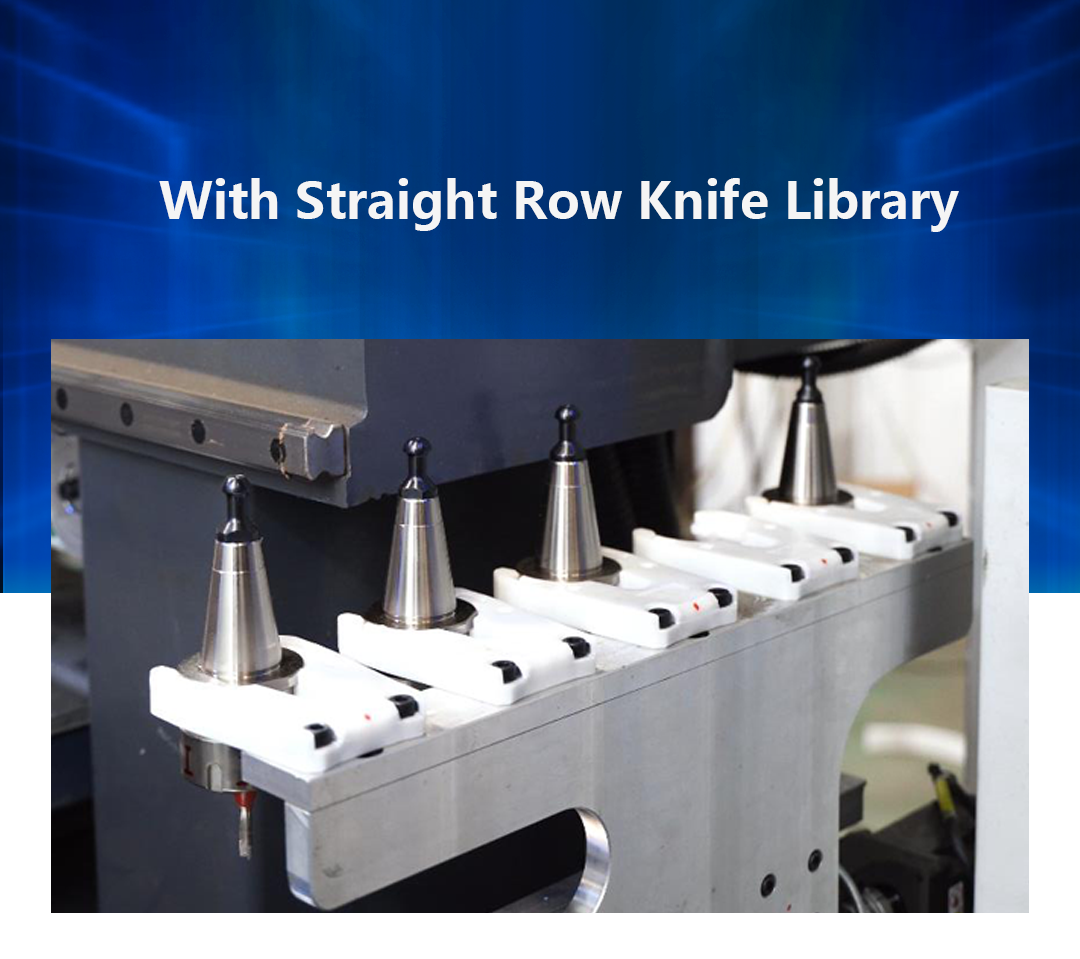

5-tool straight-row tool magazine, automatic tool change, continuous processing, meet a variety of processing needs

Suspended universal control panel, easy to rotate, easy to use

22-inch super large Philips full display, high definition

Air flotation table assists feeding and board movement, protecting the board surface from scratches

Air flotation port is different from air flotation beads, not easy to fall and get stuck, simple maintenance

Safety dust shields are installed before and after the clamping feed beam to prevent dust from falling into the rack

It can protect the safety of operators and avoid being hit by hands when moving

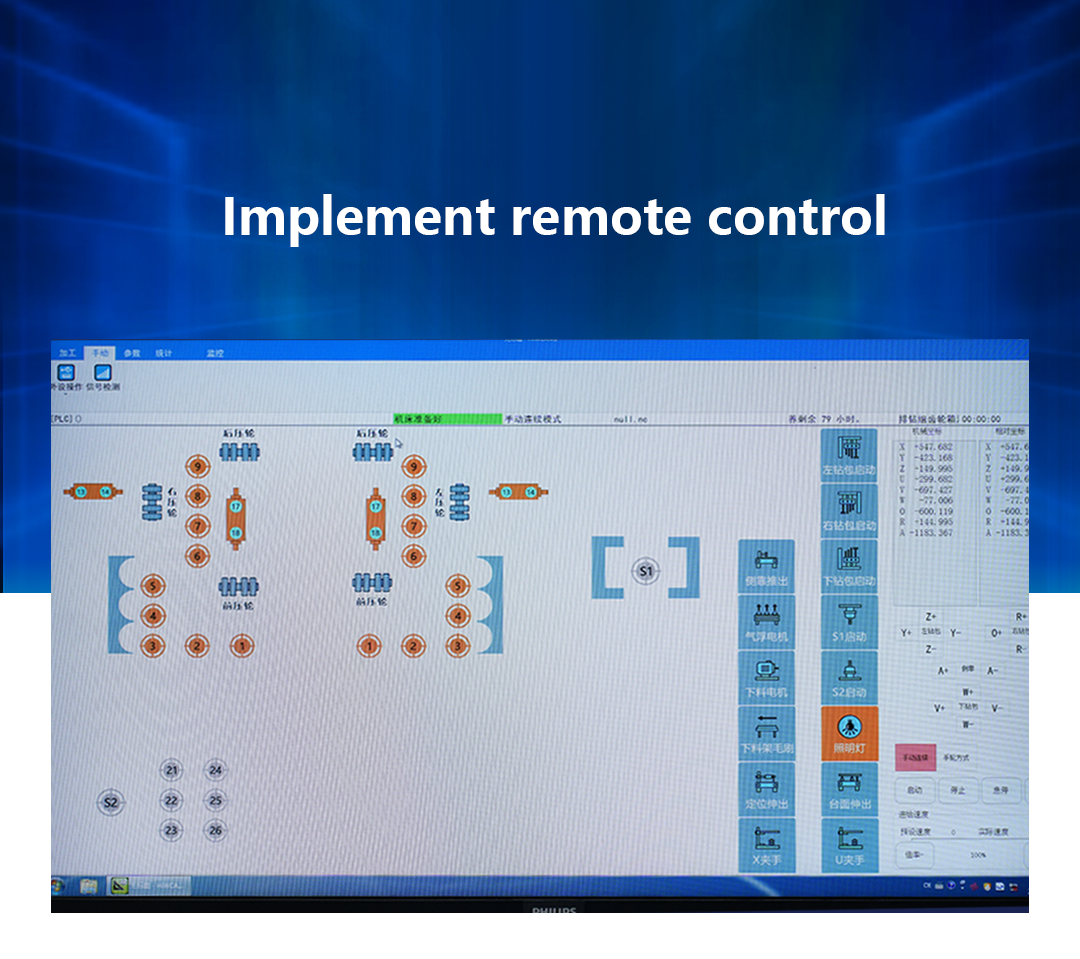

Can be connected to the Internet for remote operation, collaboration, maintenance and software upgrades

Punching, milling, grooving and other basic functions, continuous and efficient processing, high efficiency and high production capacity

Automatic spindle tool change, five straight tool magazines to meet customers' different flexible processing needs

The tool magazine can be equipped with saw blades、straight knives、 milling cutters、 lamino knives、T-type knives, etc,to process lamino,、light line grooves、side grooves、straighteners、handle-free and other processes to solve the problem of invisible parts grooving

A variety of discharge methods are available, forward front discharge, forward rear discharge, forward side discharge, and one machine can be connected to operate at least 1 person to complete the processing, powerful functions, saving labor

|

Upper horizontal drill |

4pcs*2+5 automatic tool changers |

|

Lower vertical drill |

9pcs*2 |

|

Spindle motor power |

6kw tool changer + 3kw |

|

Upper vertical drill |

6pcs |

|

X-axis clamp guide rail length |

5400mm |

|

Y-axis travel |

1200mm |

|

Z-axis travel |

150mm |

|

X-axis maximum speed |

54000mm/min |

|

Y-axis maximum speed |

54000mm/min |

|

Z-axis maximum speed |

15000mm/min |

|

Minimum processing size |

200*50mm |

|

Maximum processing size |

2800*1200mm |

|

Workpiece thickness |

12-30mm |

|

Machine dimensions |

5400*2750*2200mm |

Post time: Mar-18-2025