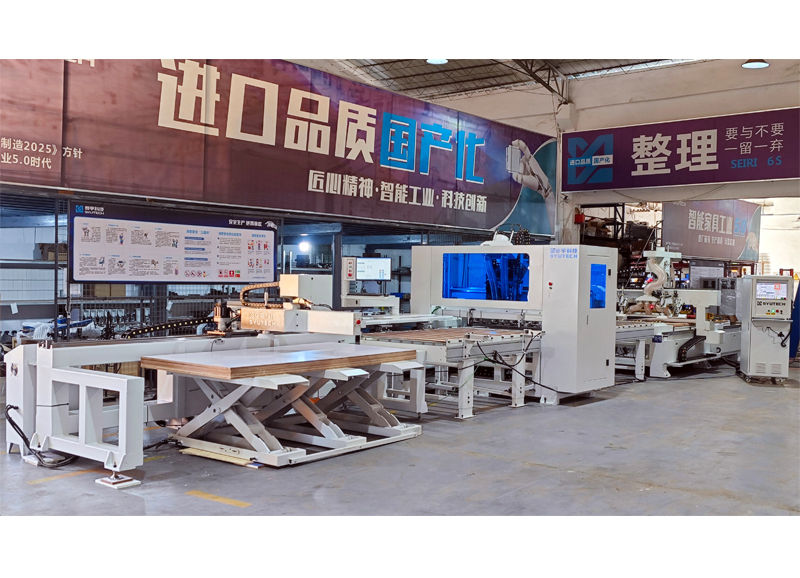

Intelligent Drilling and cutting all-in-one production line

Product Video

1.Labeling, punching, grooving, and cutting simultaneously;

2.8 hours can produce 120 pieces panels ;

3.One person manages one production line, and the board does not touch the ground to complete all processes;

4.Reduce the damage rate of the boards;

5.Reduce the chances of damage during handling, processing, and board deformation affecting accuracy;

6.Effectively reduce the probability of hole accuracy issues;

7.Great potential for future upgrades;

8.Can be connected in a production line or operated as a standalone machine;

9.Integrated control system, stable, with great potential for future development.

Machine Details

The operation interface is simple and can be connected to common design and Furniture disassembly software to automatically arrange orders for production, detect plate and workstation data in all directions in real time, and provide a clear view of processing information.

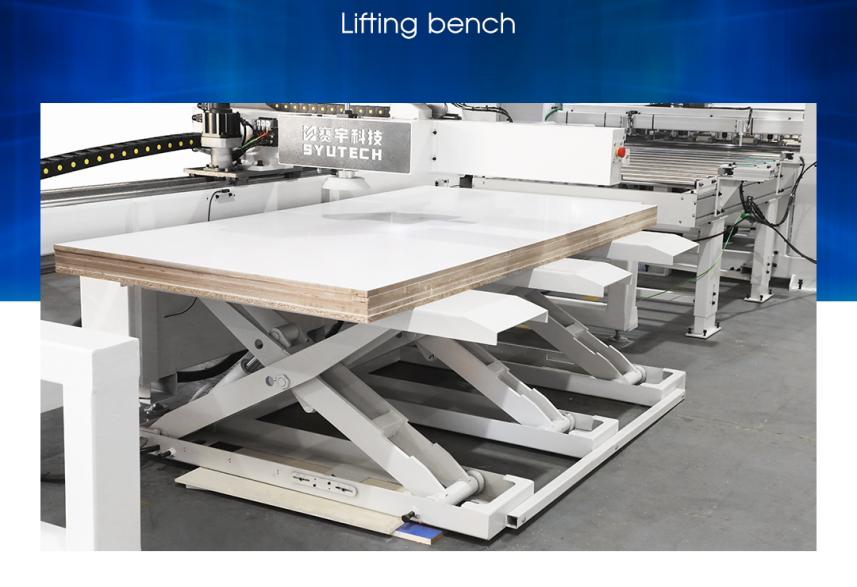

The lifting platform is convenient for loading large plates. It is equipped with a suction cup to ensure stable feeding without dropping the plate.

The lifting platform is equipped with two sets of infrared sensors to sense the position of the plate, allowing precise positioning to ensure the safety of plate delivery.

Honeywell label printer is easy to operate, prints clear labels, 90° intelligent rotation labeling, automatically adjusts the direction according to the panel for fast labeling, is efficient and stable, and can avoid the cutting area of the panel to protect the label.

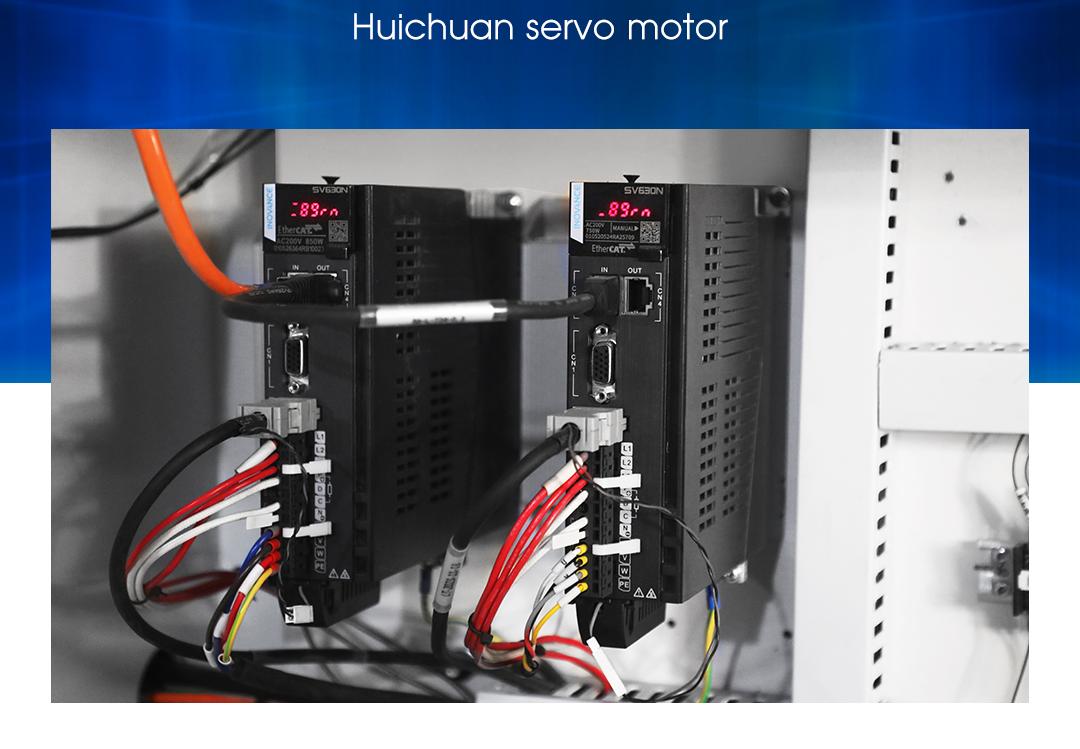

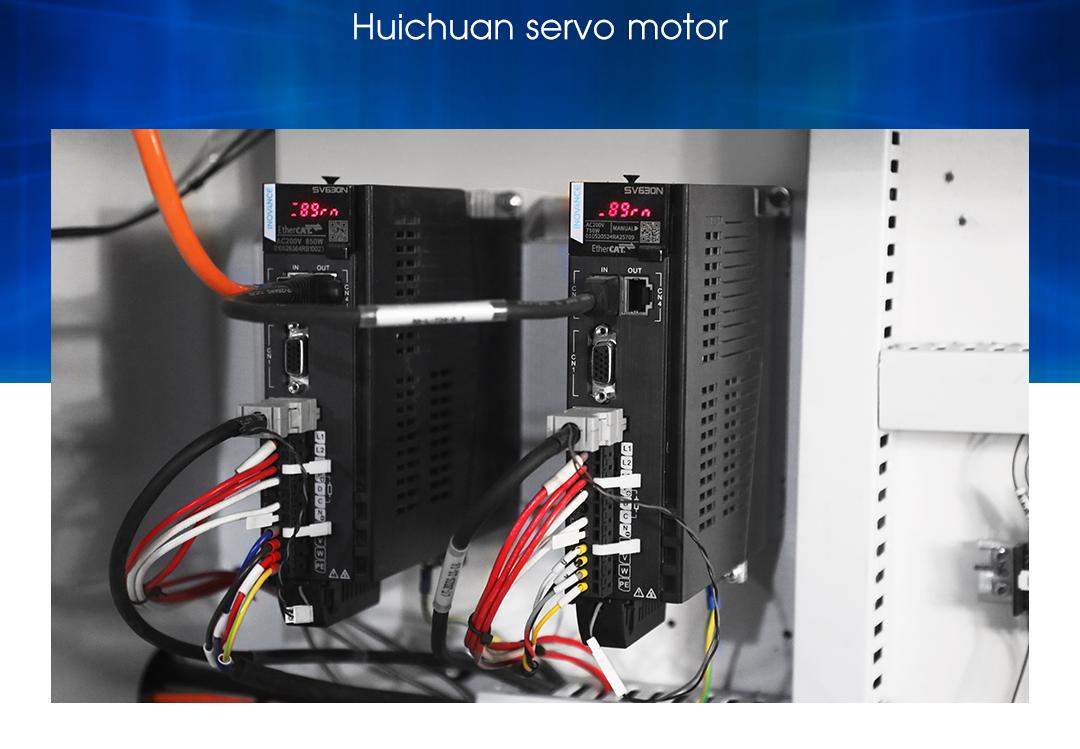

Powerful, efficient, fast, stable and durable, it can improve production efficiency and product quality.

Widen and thicken the clamps to feed the plate smoothly, and automatically adjust the clamping position according to the length of the plate.

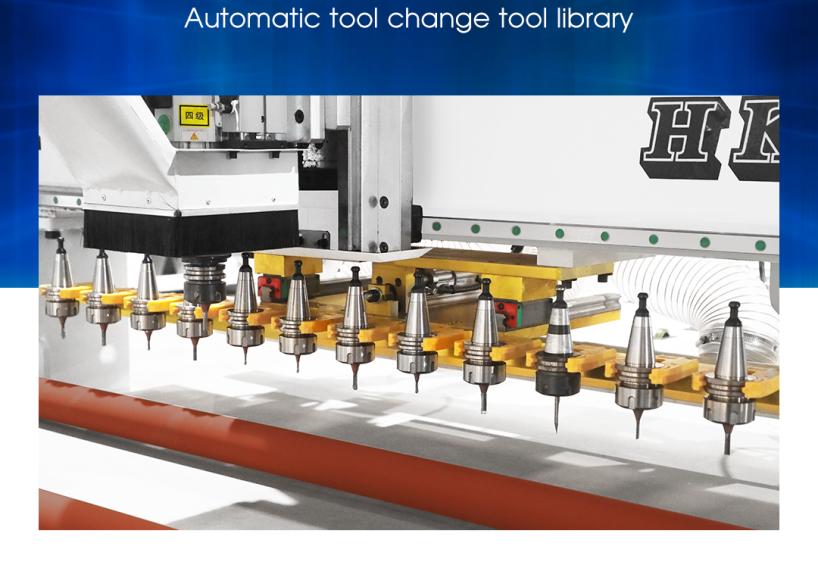

The high-speed spindle motor and in-line tool magazine can quickly and automatically change tools, enable continuous production without stopping the machine, and realize various processing processes such as engraving, milling, hollowing, and special-shaped cutting.

The upper and lower drilling packages are processed together, controlled by a servo motor, and equipped with a pressure wheel and pressure plate. The processing is stable, and the plate does not deviate or warp.

Automatic blanking and conveying saves labor, improves efficiency, seamlessly connects post-processing processes, and enables large-scale production of customized furniture in large quantities.

Applications

Parameter

|

Intelligent Drilling and cutting all-in-one production line |

|

|

Size of production line |

16500*2850*2250mm |

|

Working size |

2850*1220mm |

|

Total power |

35KW |

.Please infrom us your production requirements, quantity demands and all details, we will design best suit machine for you.