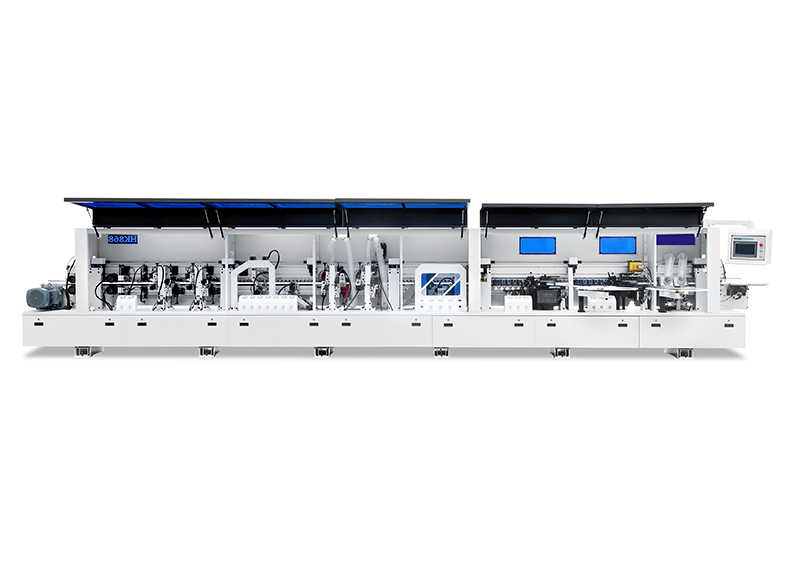

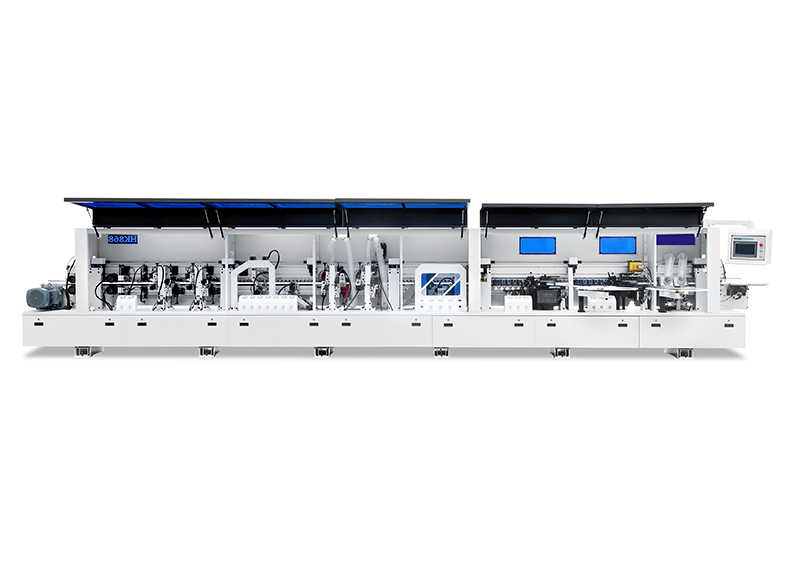

HK868P Edge Bander machine automatic

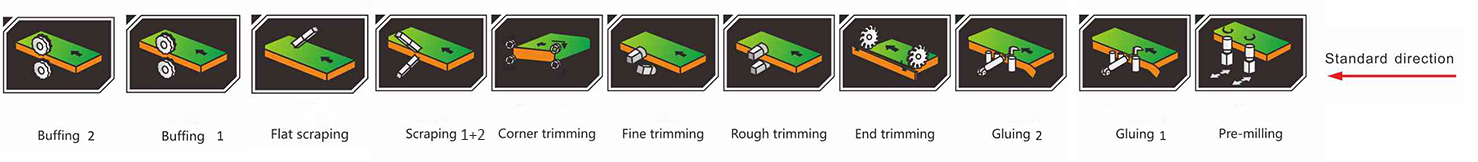

The edge banding machine is an alternative to manual edge banding procedures: conveying - gluing and welting - cutting - front and rear alignment - upper and lower trimming - upper and lower trimming - upper and lower scraping - polishing for a high degree of automation

Parameters

| Model | HK868 |

| Panel length | Min.150mm(corner trimming45x200MM) |

| Panel width | Min.40mm |

| Edge band width | 10-60mm |

| Edge band thickness | 0.4-3mm |

| Feeding speed | 18-22-25m/min |

| Installed power | 21KW380V50HZ |

| Pneumatic power | 0.7-0.9Mpa |

| Overall dimension | 9500*1200*1650mm |

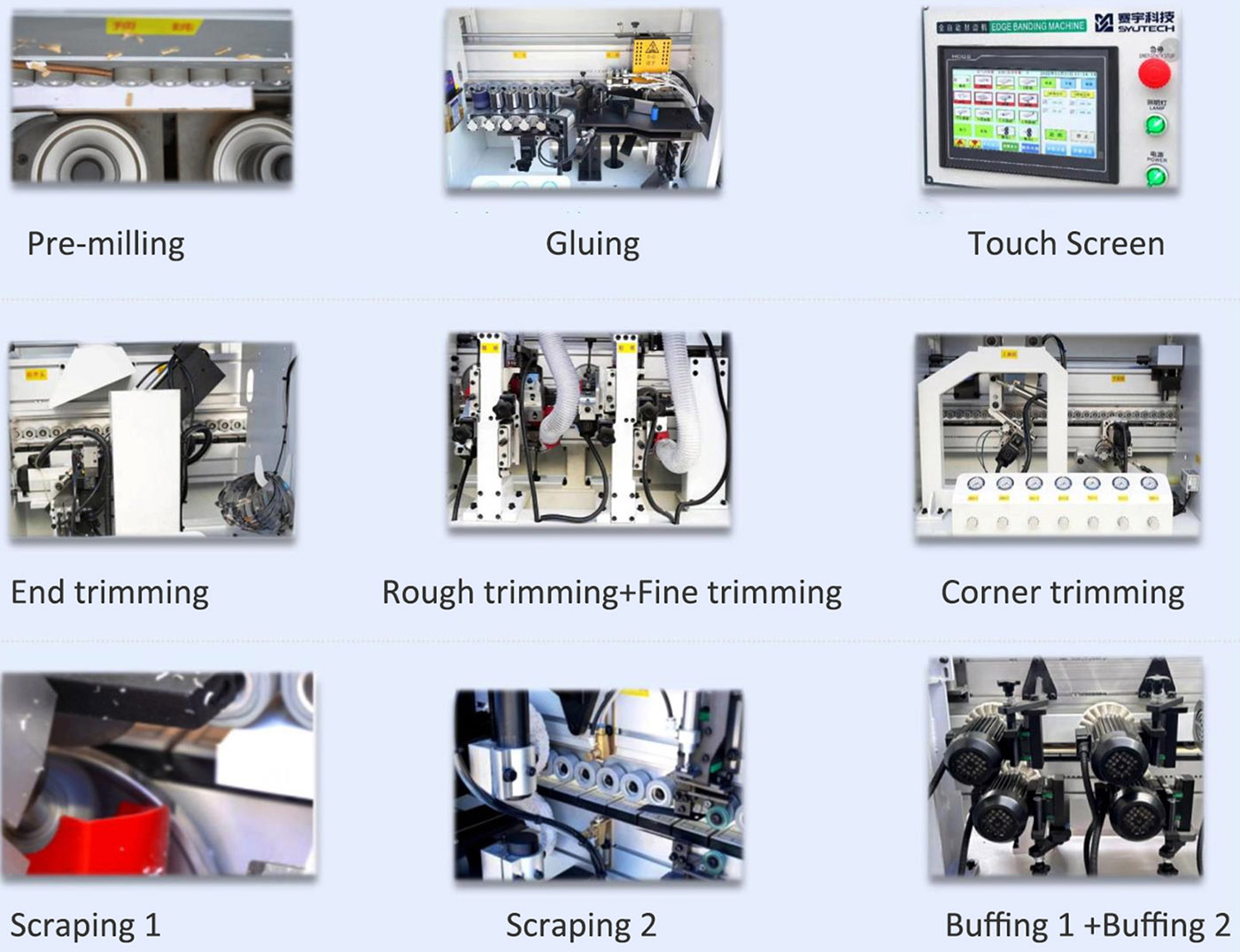

Product Function

Machine characteristics

Fully enclosed heavy-duty frame with reinforced zigzag support feet

The entire machine body has undergone annealing treatment

6 large columns+11 small columns+7 lifting boxes

Dual motor lifting enhances stability

Machine characteristics

Fully enclosed heavy-duty frame with reinforced zigzag support feet

The entire machine body has undergone annealing treatment

6 large columns+11 small columns+7 lifting boxes

Dual motor lifting enhances stability

Haisen conveying roller and chain block

Strong and durable without deformation, with a longer lifespan

Large board auxiliary bracket with four fluent strips

Equipped with narrow edge auxiliary wheels for stable plate feeding

Internet remote control system

Can be networked for temperature control and preheating in advance

Intelligent touch screen with memory function

Real time statistics of full day production capacity and recording of production situation

Internet remote control system

Can be networked for temperature control and preheating in advance

Intelligent touch screen with memory function

Real time statistics of full day production capacity and recording of production situation

The circuit adopts a Chinese English system

Convenient for power check and subsequent maintenance

Two sets of six wheel press stickers, equipped with a rubber wheel and scraper blade, automatically cleaning and non sticking adhesive residue

Two sets of six wheel press stickers, equipped with a rubber wheel and scraper blade, automatically cleaning and non sticking adhesive residue

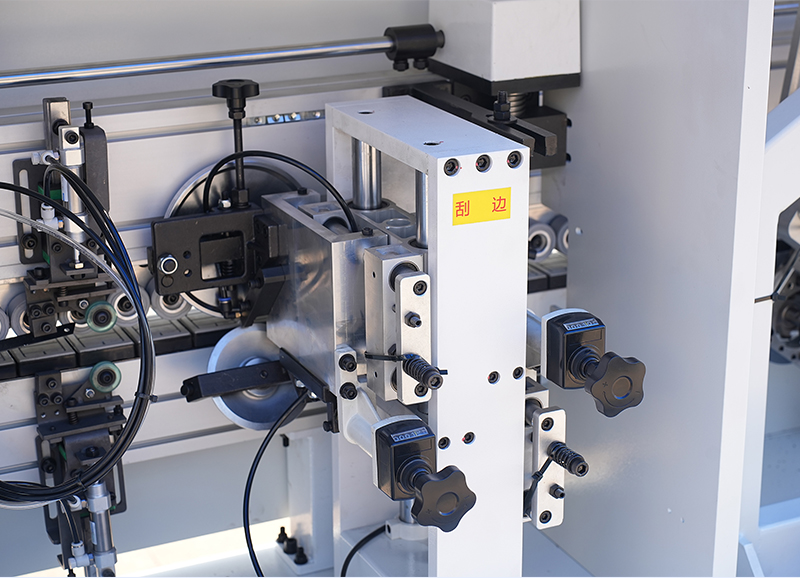

1) Two sets of upper and lower edge scraping, cabinet door and body mode can be switched with one button, without adjusting the machine

2) With directional wire blowing to prevent residual wire adhesion and prevent unstable scraping edges from causing knife jumping

Heavy Duty Rack

The machine has strong rigidity and deformation resistance, and after welding, the frame undergoes multiple processes such as aging, annealing, and five axis machine tool processing to ensure processing accuracy and long-term stability.

Heavy Duty Rack

The machine has strong rigidity and deformation resistance, and after welding, the frame undergoes multiple processes such as aging, annealing, and five axis machine tool processing to ensure processing accuracy and long-term stability.

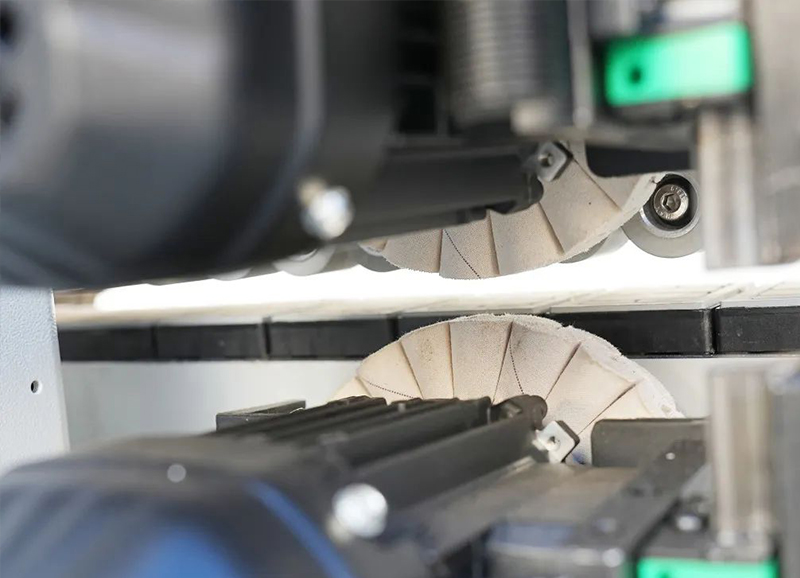

Syutech Patent Convenient Polishing

Double polishing, removing dust and adhesive residue, keeping the board surface clean

Samples