HK612B-C Six side cnc drilling machine

Product Video

Technical Parameters

| Model | HK612B-C |

| Length of X-axis clamp guide rail | 5400mm |

| Y-axis stroke | 1200mm |

| X-axis stroke | 150mm |

| Max speed of X-axis | 54000mm/min |

| Max speed of Y-axis | 54000mm/min |

| Max speed of Z-axis | 15000mm/min |

| Min processing size | 200*50mm |

| Max processing size | 2800*1200mm |

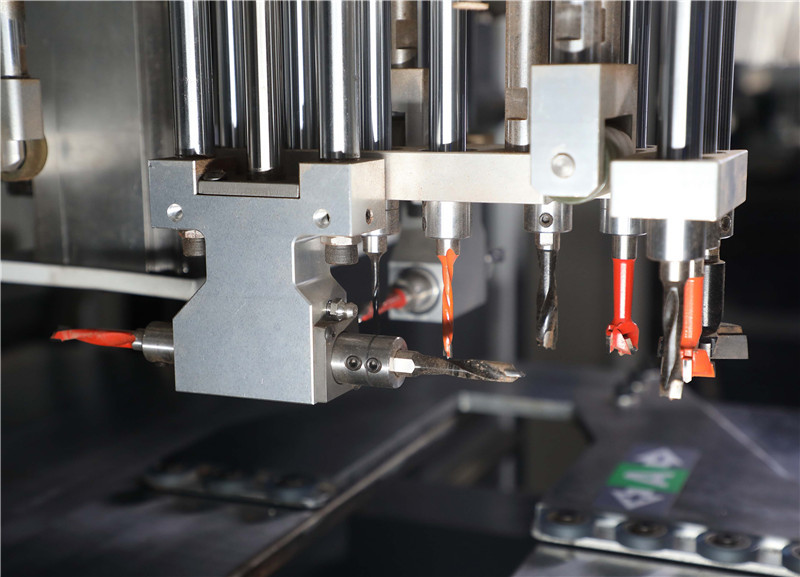

| Number of top drilling tools | Vertical drilling tools 9pcs*2 |

| Number of top drilling tools | Horizontal drilling tools 4pcs*2(XY) |

| Number of bottom drilling tools | Vertical drilling tools 6pcs |

| inverter | inovance inverter380V 4kw* 2 set |

| Main spindle | HQD 380V 4kw* 2 set |

| Workpiece thickness | 12-30mm |

| Drilling package brand | Taiwan brand |

| Machine with automatic tool change | 0.4kw |

| Machine size | 5400*2750*2200mm |

| Machine weight | 3900kg |

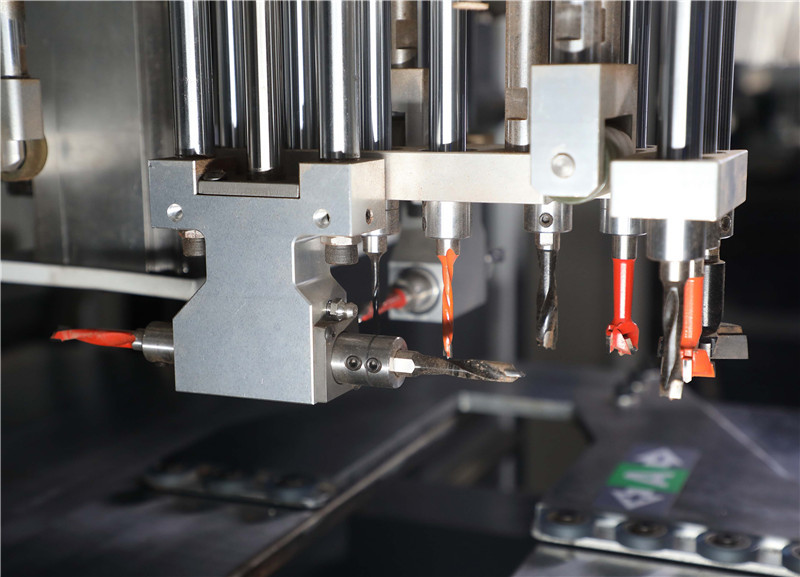

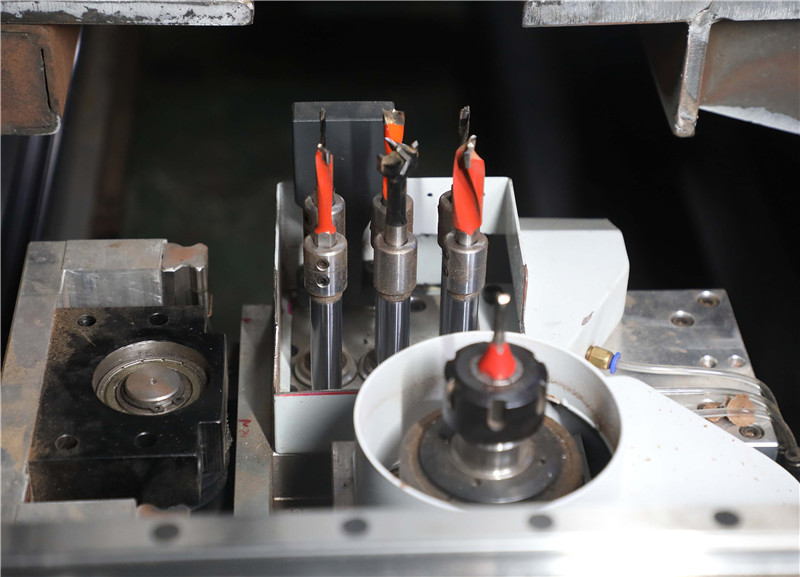

Direct automatic tools change library (can install 5 pcs tools)

Automatically changes to the tool, The function help the six side cnc drilling machine meet the variety of processing needs

Direct automatic tools change library (can install 5 pcs tools)

Direct discharge tool library automatically changes to the tool, continuous and efficient processing to meet a variety of processing needs

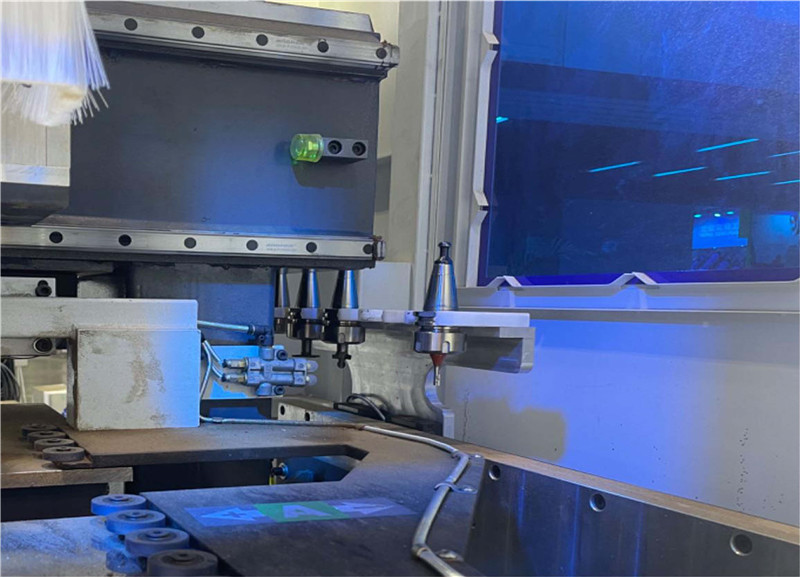

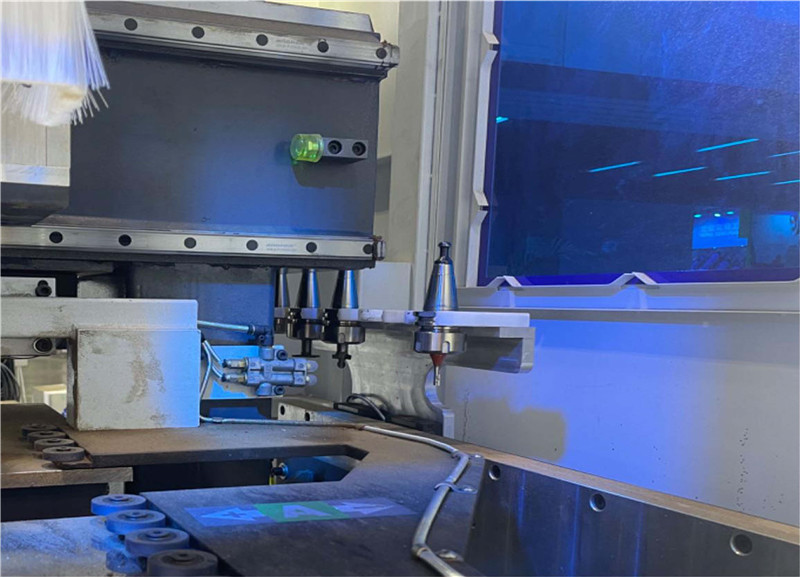

Machine consist of two drilling bags + one bottom drilling bag.

Two high -precision upper drill bags, efficient processing

CNC Six -sided double drilling bag increases processing efficiency of more than 20% compare with the single drilling bag.

Six-sided processing

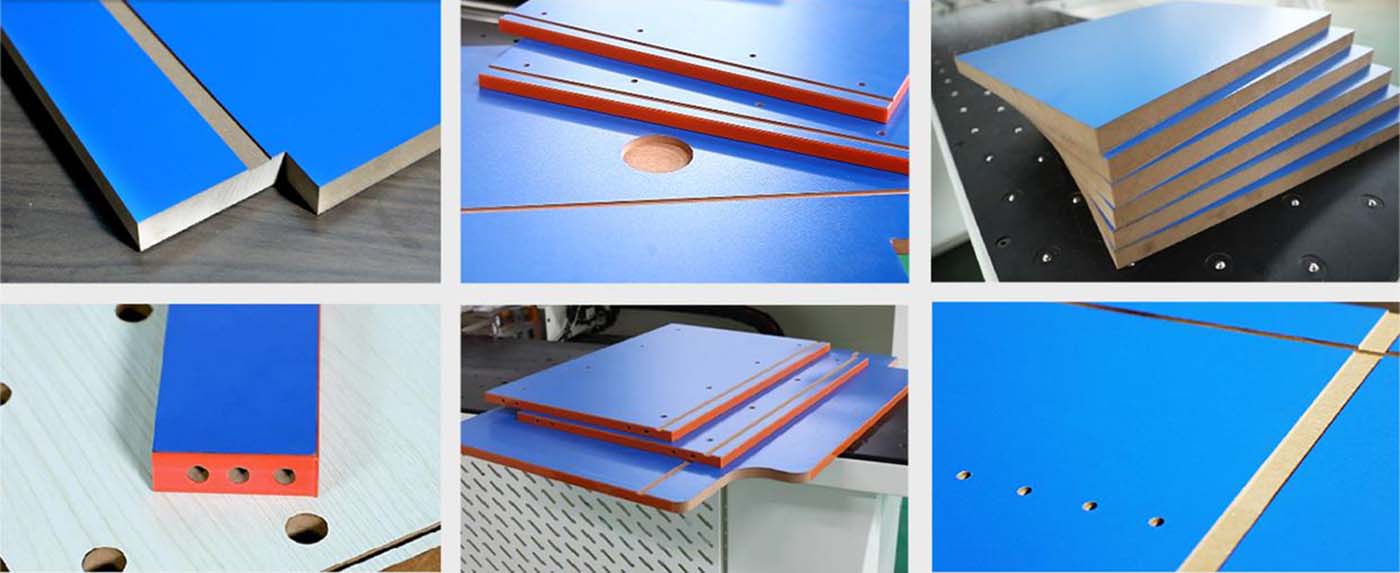

One time processing can complete panel 6-side drilling & 2-side grooving, and 4 sides slotting or Lamello works.Minimum processing size for the plate is 40*180mm

Dual drilling package can process with a minimum hole spacing of 75mm.

The upper drilling bag((9 pcs top vertical drilling 9pcs*2pcs + top horizontal drilling 6pcs)

For the new model cnc drilling machines,we have update top vertical drilling 10 pcs+8 horizotal drillings

The upper drilling bag((9 pcs top vertical drilling 9pcs*2pcs + top horizontal drilling 6pcs))

The bottom drilling bag:(6pcs)

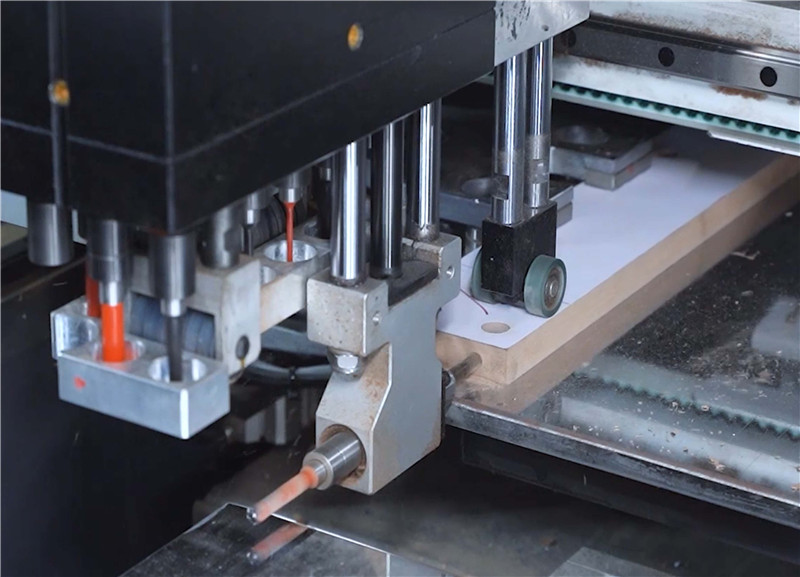

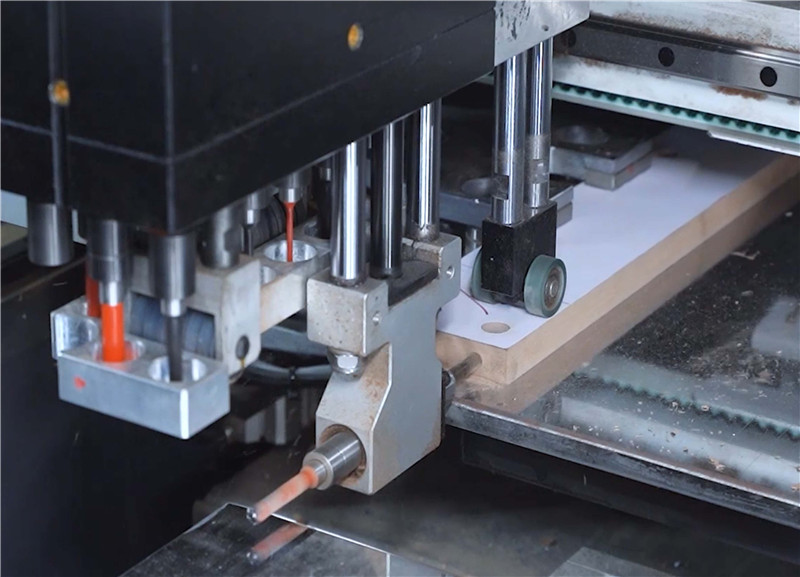

Press wheel pressure plate integrated molding

The drilling bag comes with a pressure wheel pressure plate, which is integrated and tightly. It can instantly press the board in the instant when processing, so that the board is always straight and the processing is more accurate

Press wheel pressure plate integrated molding

The drilling bag comes with a pressure wheel pressure plate, which is integrated and tightly. It can instantly press the board in the instant when processing, so that the board is always straight and the processing is more accurate

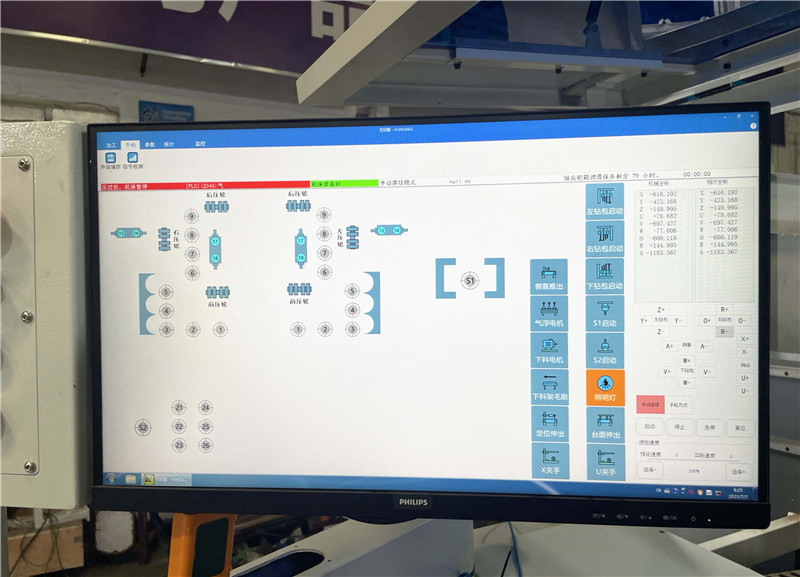

19 inch large screen control, Hydemon control system,matched with CAM software

Equipped with CAM software, can be connected to cutting machine/edge banding machine

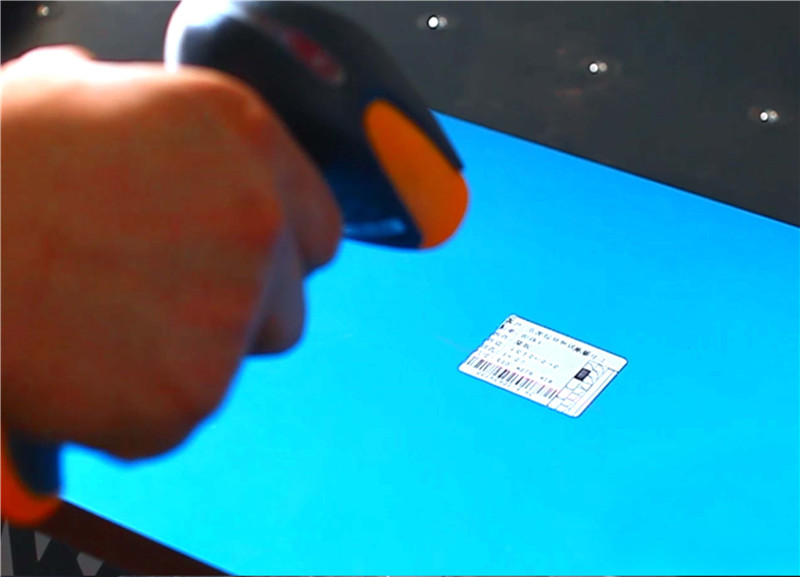

Intelligent industrial control integration

code scanning processing,high degree of automation

Intelligent industrial control integration

code scanning processing,high degree of automation

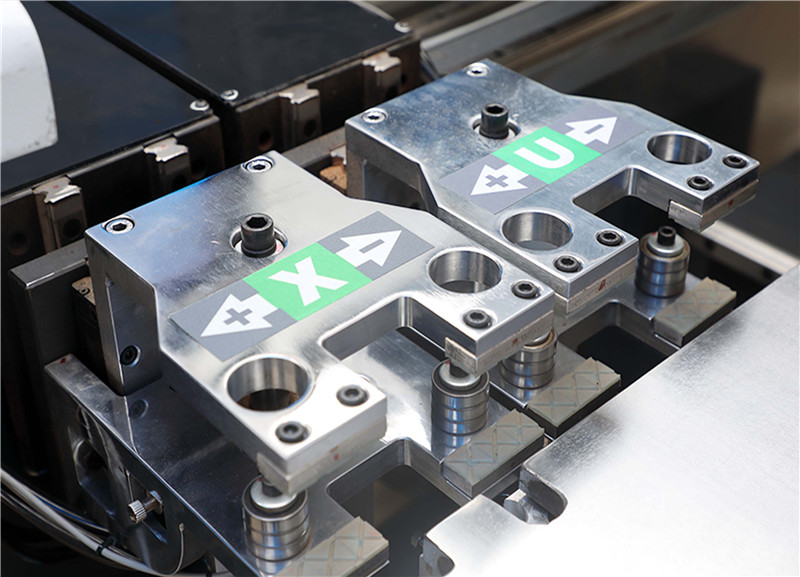

Double clamps

The double gripper mechanism is adopted to automatically control the feeding and positioning of the panel according to the computer drilling program.

The frame is precision machined using a machining center.

The heavy-duty machine body is meticulously welded and undergoes annealing and aging treatment.

The 5.4-meter extended beam is made of thickened box-section beams.

It is welded to form a strong and rigid structure.

The frame is precision machined using a machining center.

The heavy-duty machine body is meticulously welded and undergoes annealing and aging treatment.

The 5.4-meter extended beam is made of thickened box-section beams.

It is welded to form a strong and rigid structure.

Inovance servo motor

Inovance absolute value AC servo control, paired with Xinbao reducer, with an accuracy of ±0.1mm.

Taiwan Ande Guide Rail

Lightweight Slider Rail Smooth and precise operation, strong wear resistance and rigidity

High load-bearing capacity

Taiwan Ande Guide Rail

Lightweight Slider Rail Smooth and precise operation, strong wear resistance and rigidity

High load-bearing capacity

Japanese Shinbao Reducer

High precision, low noise, strong rigidity

Easy maintenance, long service life

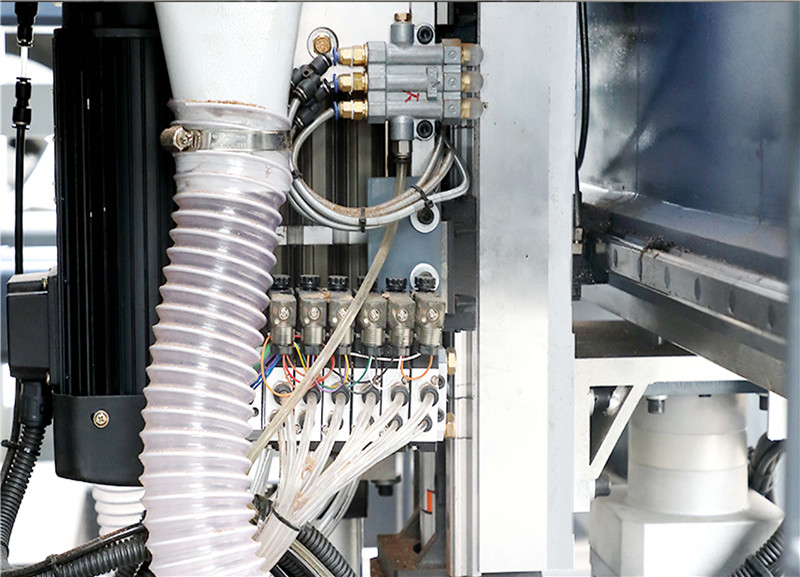

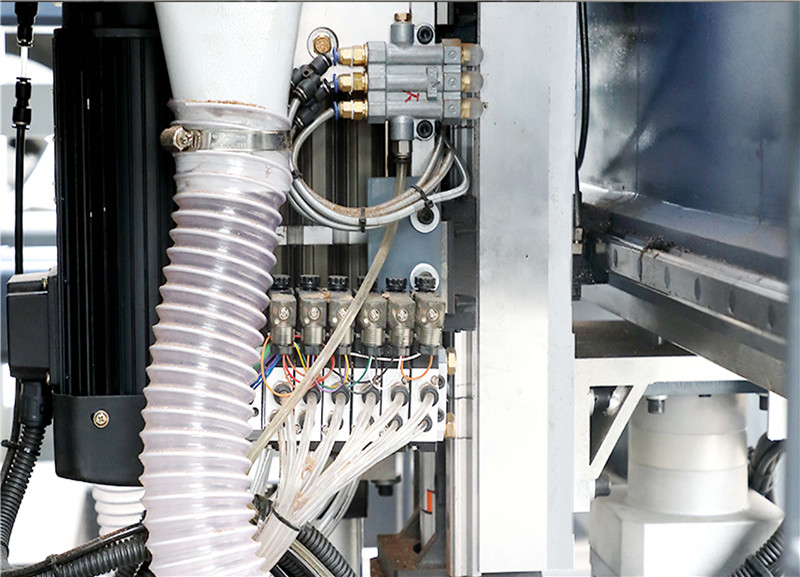

Exclusive Pneumatic Control

Traditional spring control is prone to wear and tear

Upgraded technology adopts pneumatic control for vertical movement

Maintains long-term precision

Thickened 6mm drill package with air pipe to prevent inconsistent drilling depth

Guaranteed drilling depth

Exclusive Pneumatic Control

Traditional spring control is prone to wear and tear

Upgraded technology adopts pneumatic control for vertical movement

Maintains long-term precision

Thickened 6mm drill package with air pipe to prevent inconsistent drilling depth

Guaranteed drilling depth

Accurate transmission positioning

Diameter 30mm lead screw + German 2.0 module high-precision helical gear, with better rigidity and higher precision

Gapless copper bushing for positioning cylinder

Lower beam adopts dual guide rails for more stability

Chrome-plated processing tabletop

The processing countertop is fixed as a whole in front.

When drilling horizontal holes, the back can be moved.

To prevent tilting and ensure stable processing.

Chrome-plated processing tabletop

The processing countertop is fixed as a whole in front.

When drilling horizontal holes, the back can be moved.

To prevent tilting and ensure stable processing.

Widened air flotation platform 2000*600mm widened air flotation platform

Effectively protects the surface of the sheet from scratching

Optional loading and unloading modes: front in/front out or rear out Can be connected to a rotating line.

Automatic oil supply system

Fully automatic high-pressure gear electric oil pump

Microcomputer-controlled automatic oil supply

Automatic oil supply system

Fully automatic high-pressure gear electric oil pump

Microcomputer-controlled automatic oil supply

Advantage

High efficiency and high productivity:

100 sheets can be processed in 8 hours per day with six-sided drilling and grooving.

Samples