HK6 CNC router machine

Product Video

Technical parameters

| X axis working arrange | 1300mm |

| Y axis working arrange | 2800mm |

| Z axis working arrange | 250mm |

| Max Air Move Speed | 10000mm/min |

| effective processing speed | 30000mm/min |

| Axis rotation speed | 0-18000rpm |

| Processing presicion | ±0.03mm |

| Main spindle power | HQD 9kw air cold high speed spindle |

| Servo motor power | 1.5kw*4pcs |

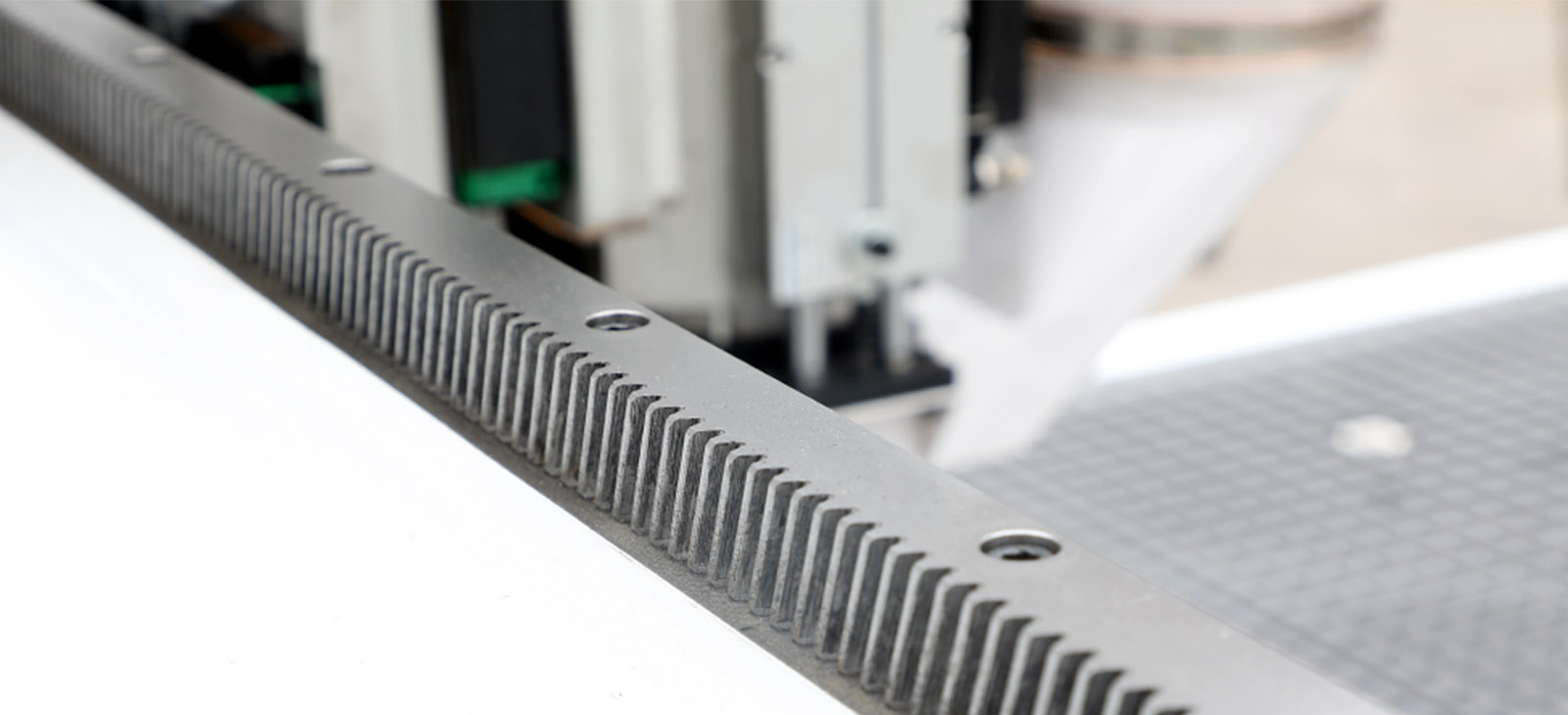

| Mode of X/Y axis drive | German 2-ground high-precision rack and pinion |

| Mode of Z axis drive | Taiwan High Precision Ball Screw |

| Effective machining speed | 10000-250000mm |

| Table structure | Vacuum adsorption of 24 holes in 7 regions |

| Machine body structure | heavy-duty rigid frame |

| reduction gears box | Japanese Nidec Gearbox |

| Positioning System | Automatic positioning |

| Machine size | 4300x2300x2500mm |

| Machine weight | 3000kg |

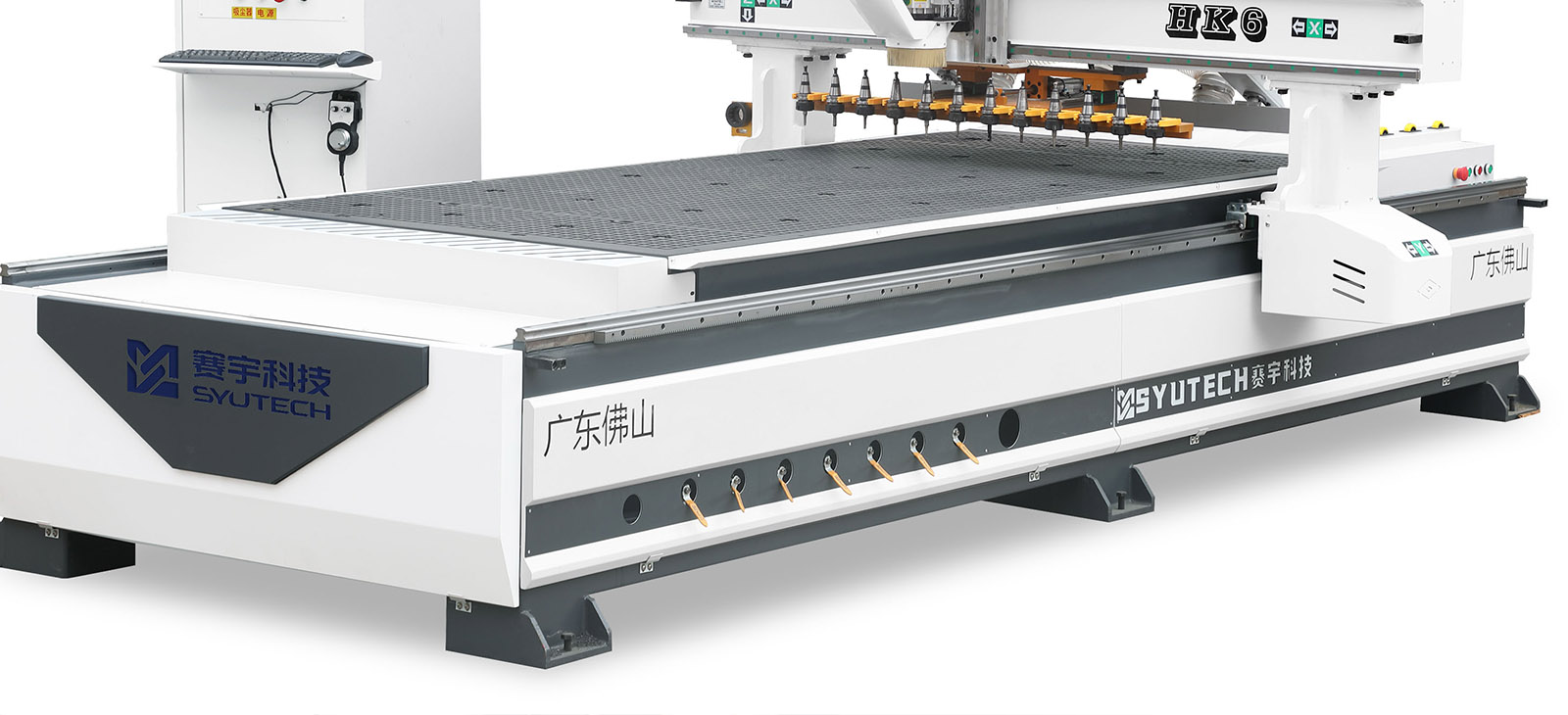

Heavy machine body

Our cnc router machine thickened frame, five-axis milling machine processing

High-temperature quenching treatment

The total length of the machine is 4.3 meters and weighs 3.5 tons

The whole board vacuum adsorption table, stable and not warping

Can process standard four nine-foot large boards

Heavy machine body

Thickened frame, five-axis milling machine processing

High-temperature quenching treatment

The total length of the machine is 4.3 meters and weighs 3.5 tons

The whole board vacuum adsorption table, stable and not warping

Can process standard four nine-foot large boards

Automatic tool changer

12 straight-line tool changer, complete with various tools

Multiple tools can be freely switched for continuous production without stopping the machine.

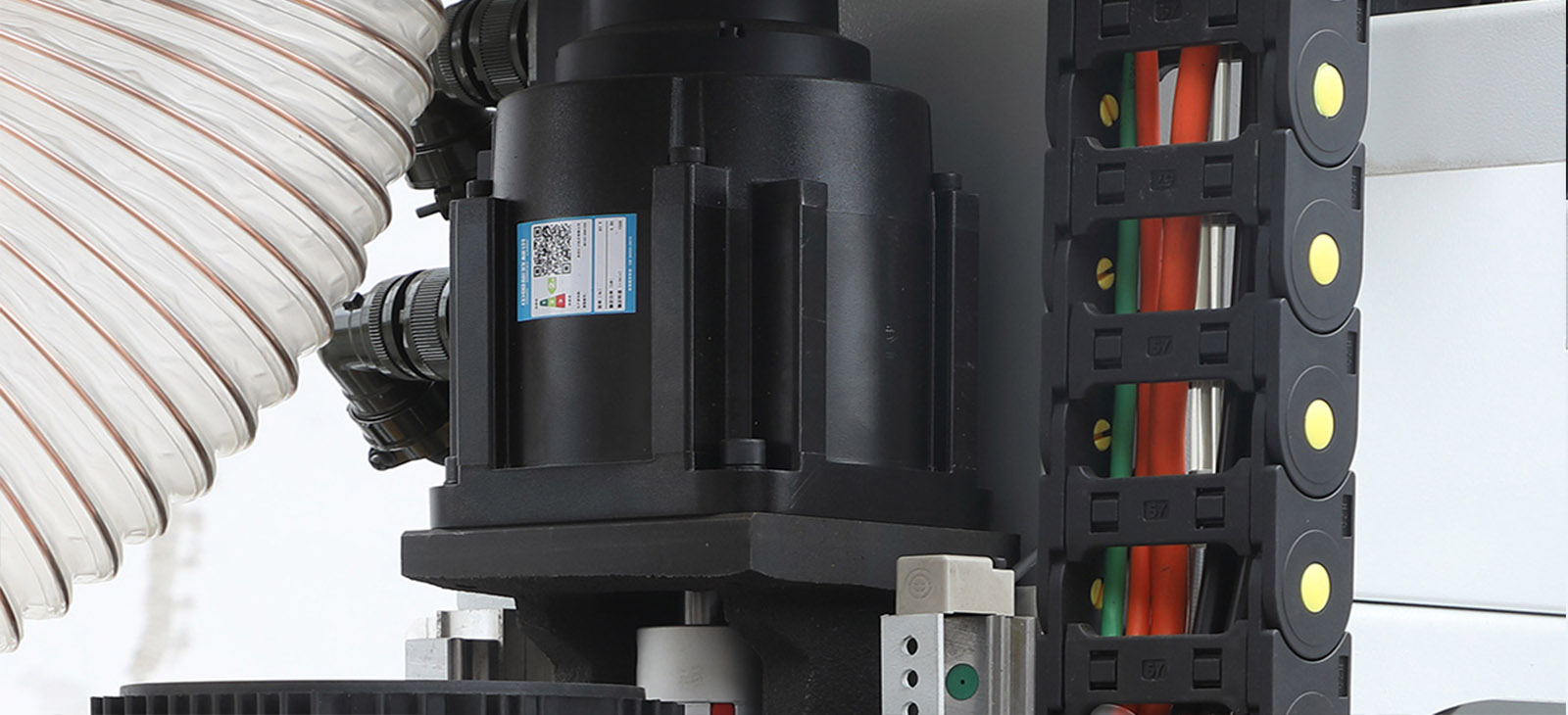

Inovance servo motor

Adopting Inovance servo motor, with strong control performance, high precision, and reduced equipment failure rate.

Complete set of Inovance configuration, including Inovance inverter + driver + specially matched imported cables, durable and long-lasting.

High-power tool change spindle

Adopting HQD9KW air-cooled high-speed spindle motor

Switching tools is more convenient

Japanese Nidec Gearbox

High precision, low noise, and strong rigidity

Easy maintenance and long service life

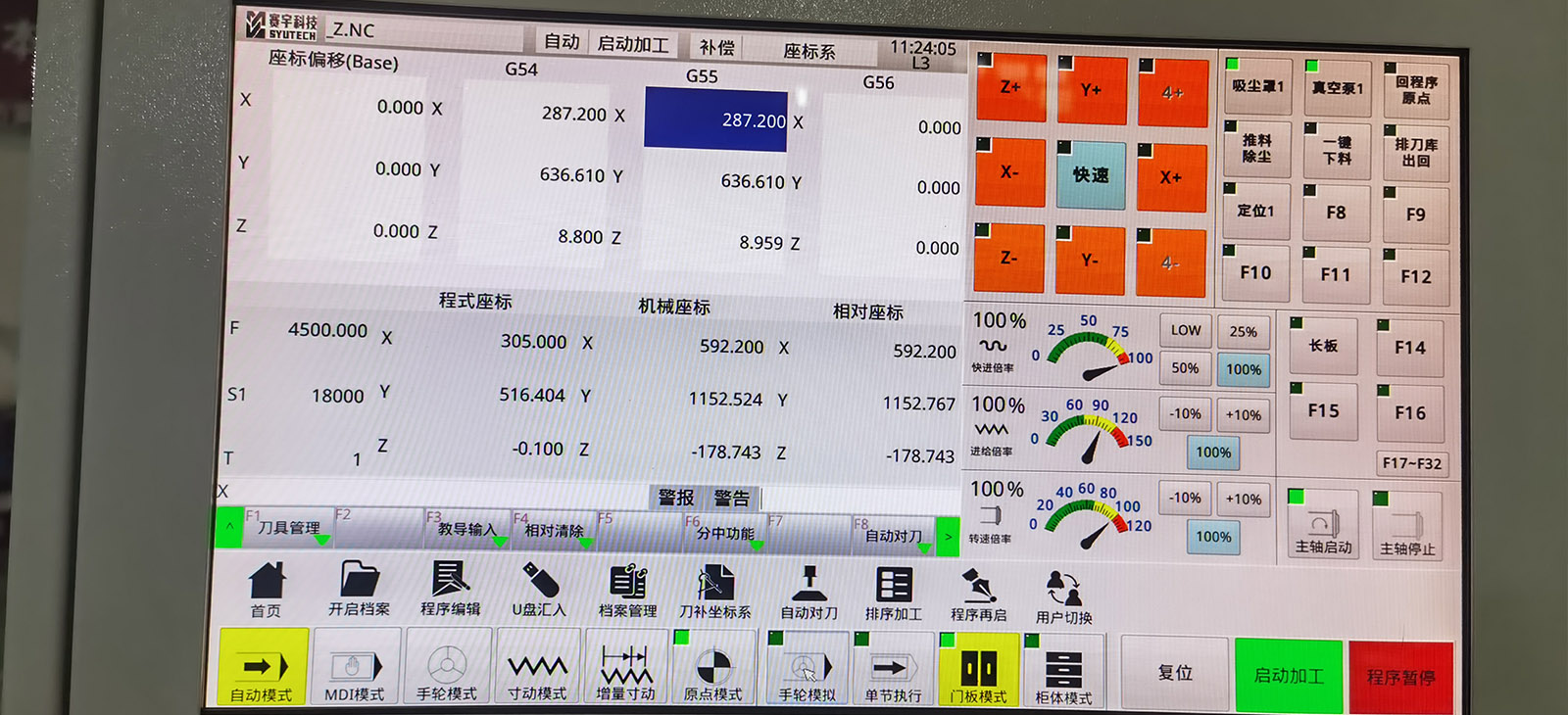

Taiwan Bao Yuan Control System

Simple user interface, high stability

Used for high-end equipment or automatic production line.

Transmission accuracy

German high-precision rack + Taiwanese high-precision ball screw + Taiwanese linear guide.

Low loss, long-lasting durability.

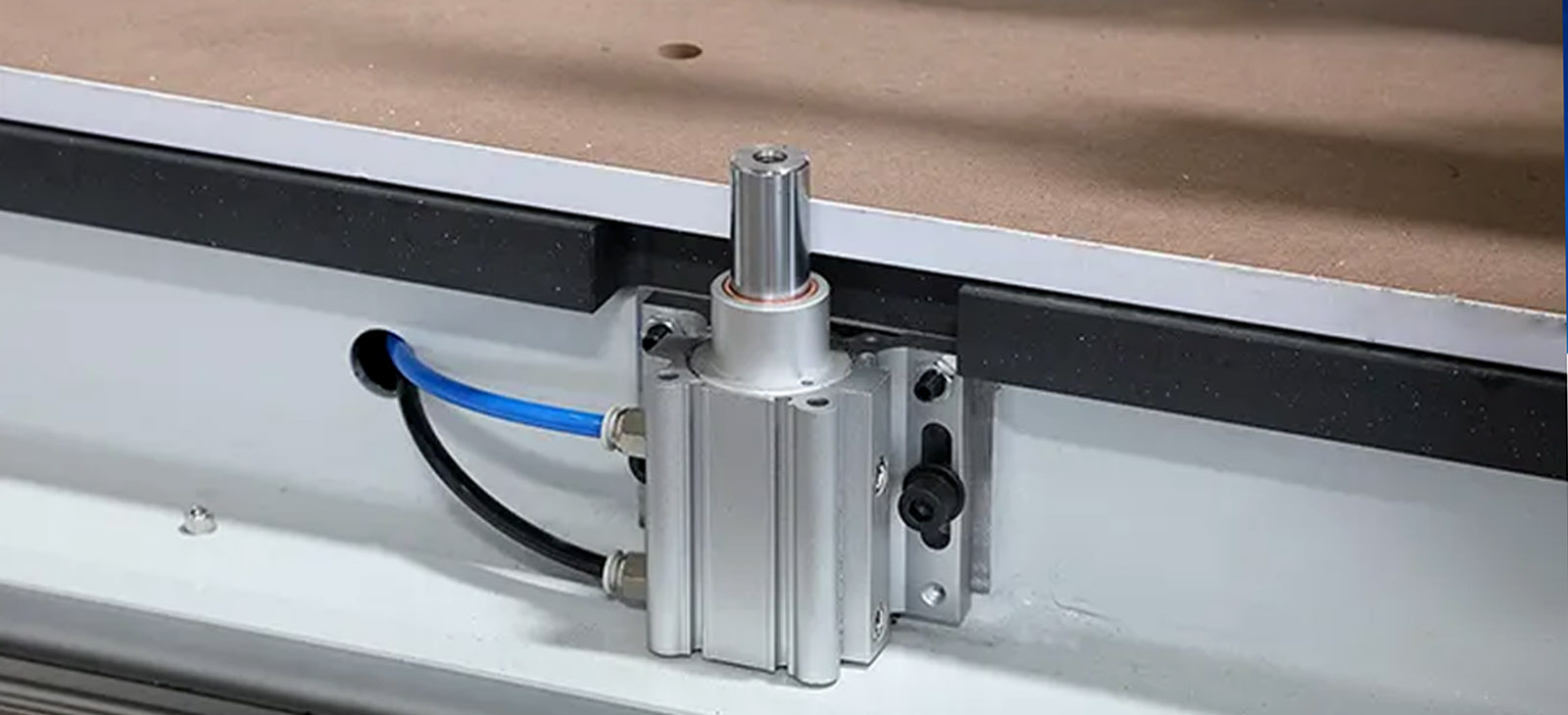

Precise positioning

repetitive positioning structure, 3+2+2 automatic positioning cylinders

accuracy can be controlled within ±0.03mm

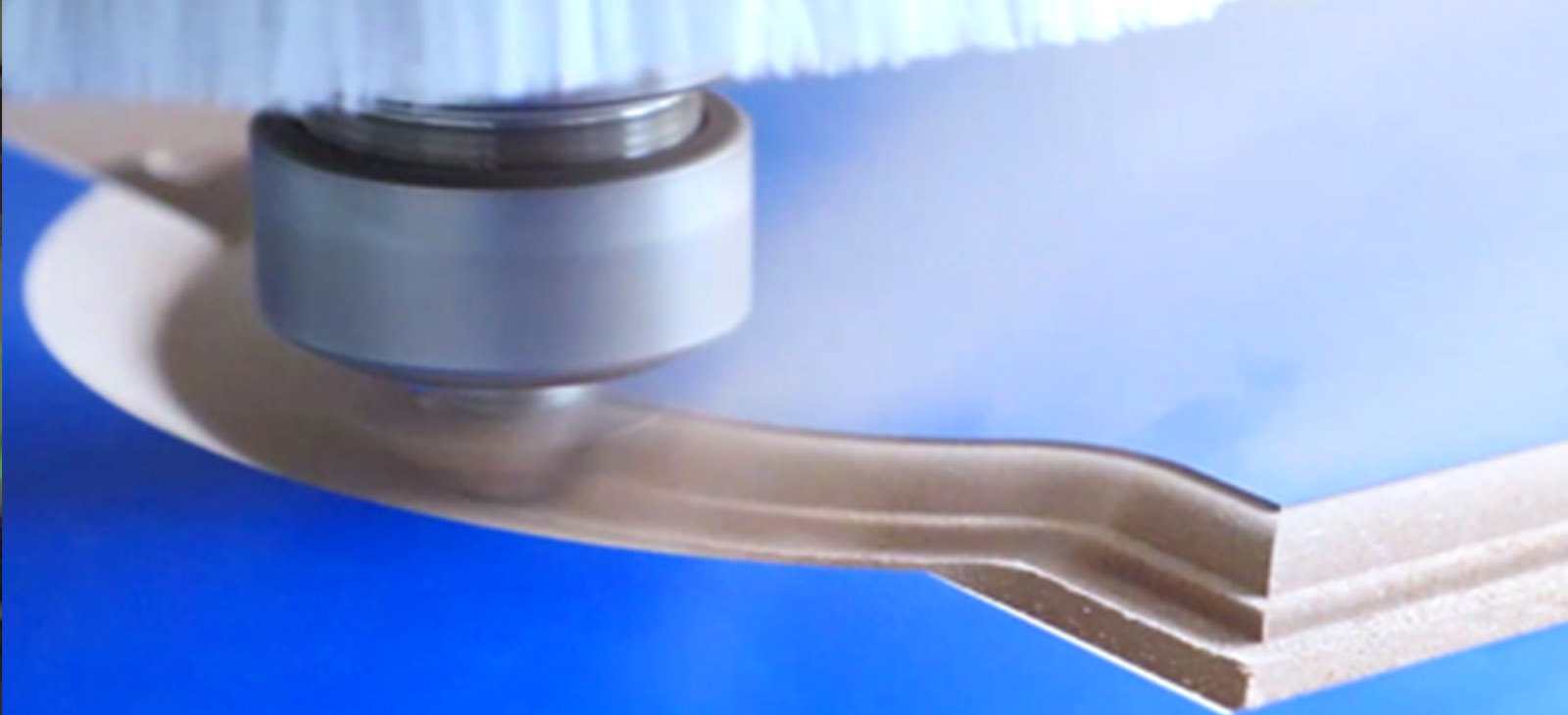

Automatic Tool Setter

Up-and-down floating automatic tool setter

Accurate machining, reducing machine downtime

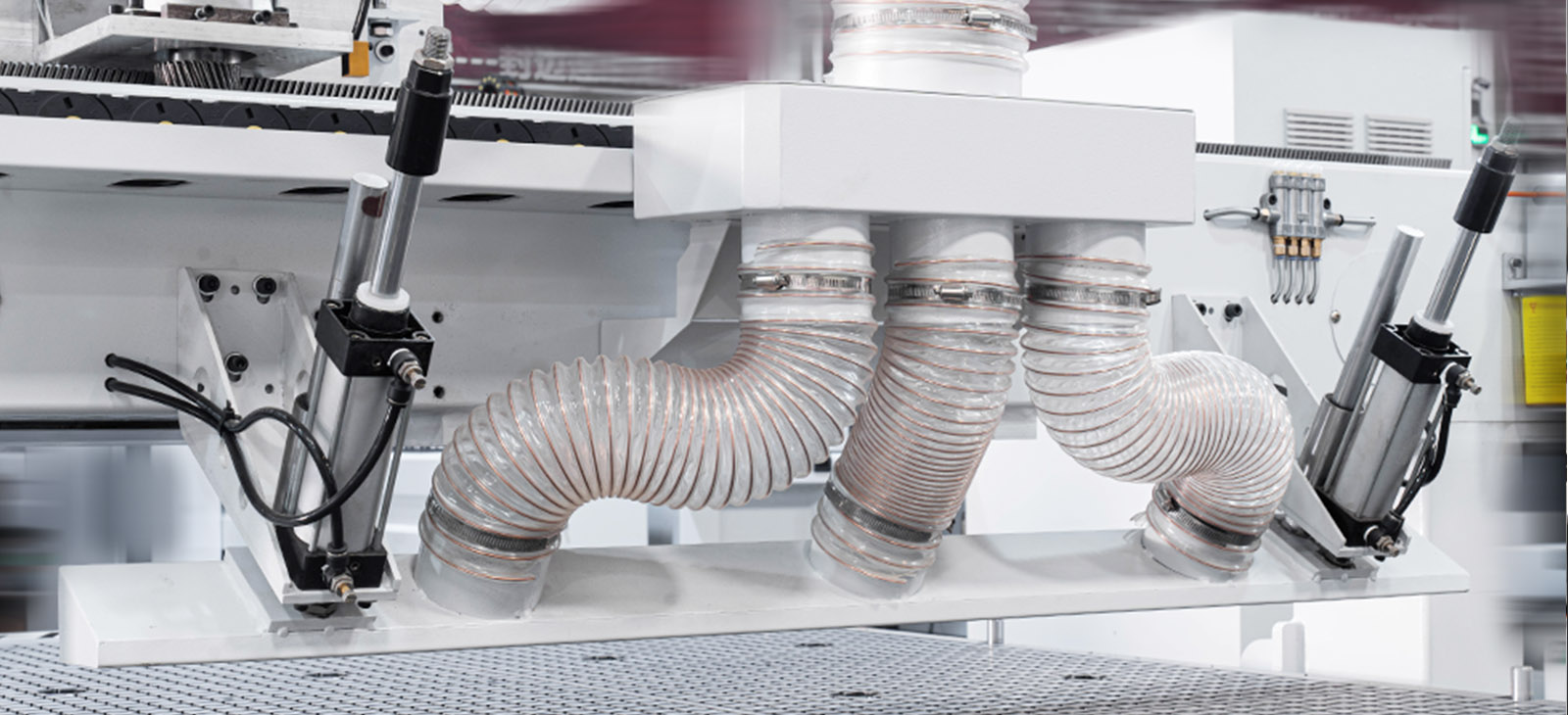

Auto cylinder feeding

Cylinder feeding, adding welding guide pillars

Assisted feeding with wheels for more stable material feeding

Automatic Fueling System

Automatic timed oil injection system, metered oil distribution

One-click operation, time-saving and worry-free.

Core Advantages

Reducing labor costs

By designing layouts, processing production, and handling materials, one person can operate multiple machines, saving a significant amount of labor expenses.

Core Advantages

Save on Sheet Materials

Automated cutting software that automatically splits and intelligently arranges materials, increasing sheet material utilization, reducing waste, and saving production costs.

Core Advantages

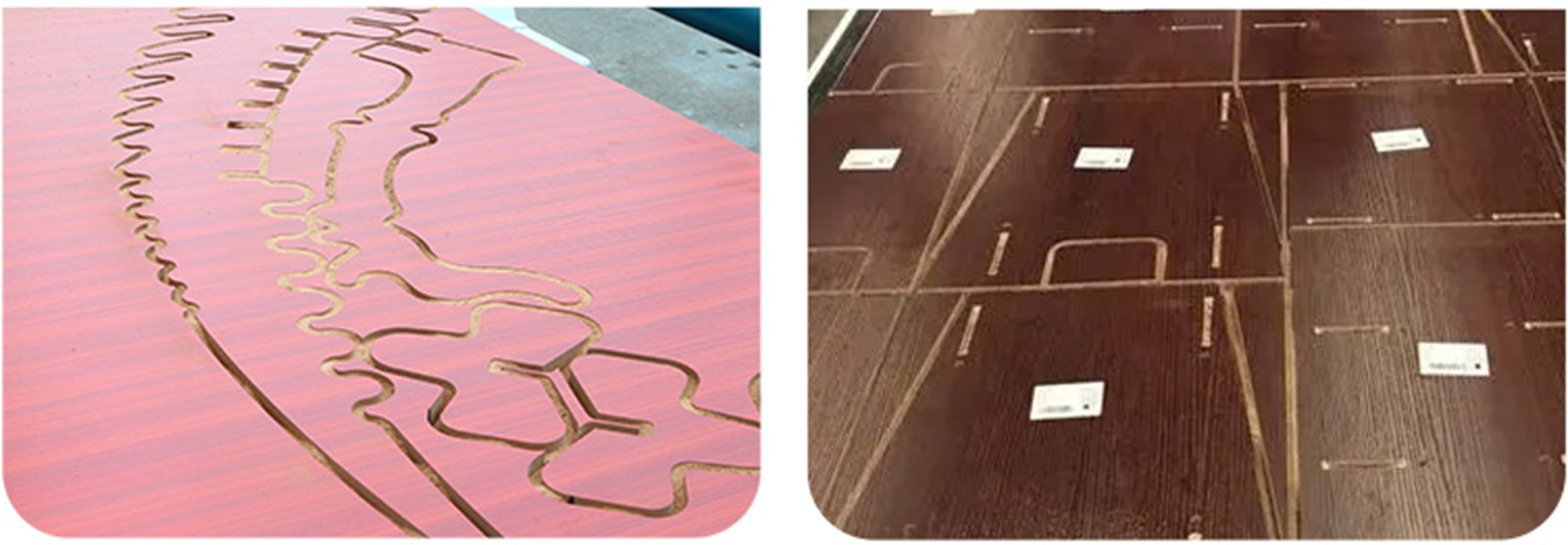

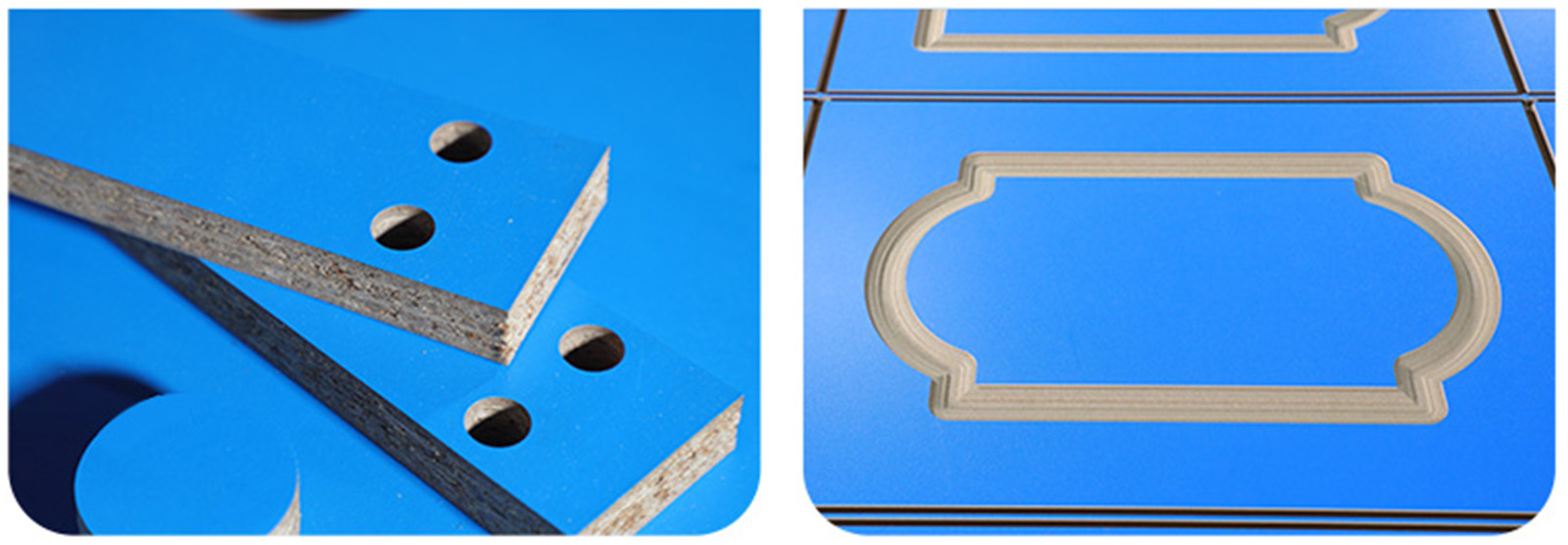

Multi-function

It can engrave, cut, mill, drill, slot, and chamfer. It can also cut irregular shapes. One machine can handle multiple processes.

Core Advantages

High Efficiency

Fast speed, high production capacity, accurate precision, minimal dust, automation, high efficiency and reliability.

Suitable for customized panel furniture production lines, wardrobes, cabinets, office furniture etc

Product Exhibition