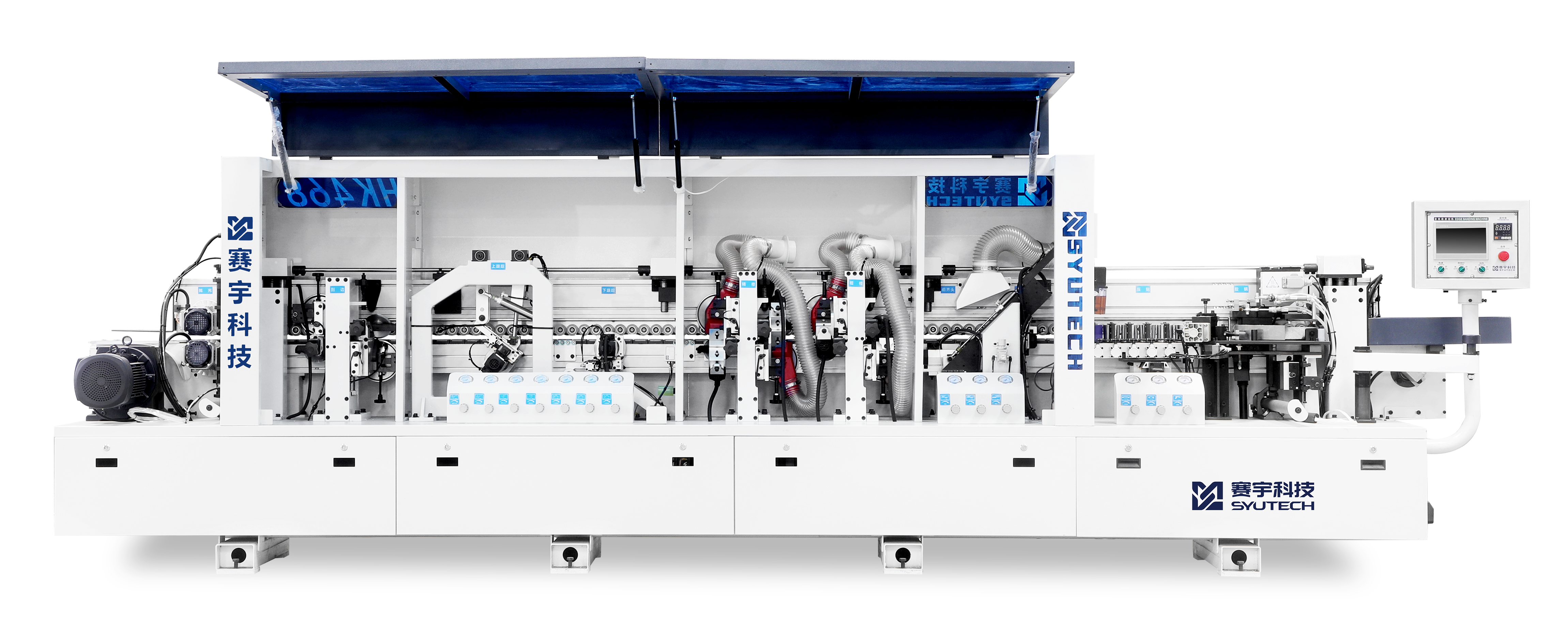

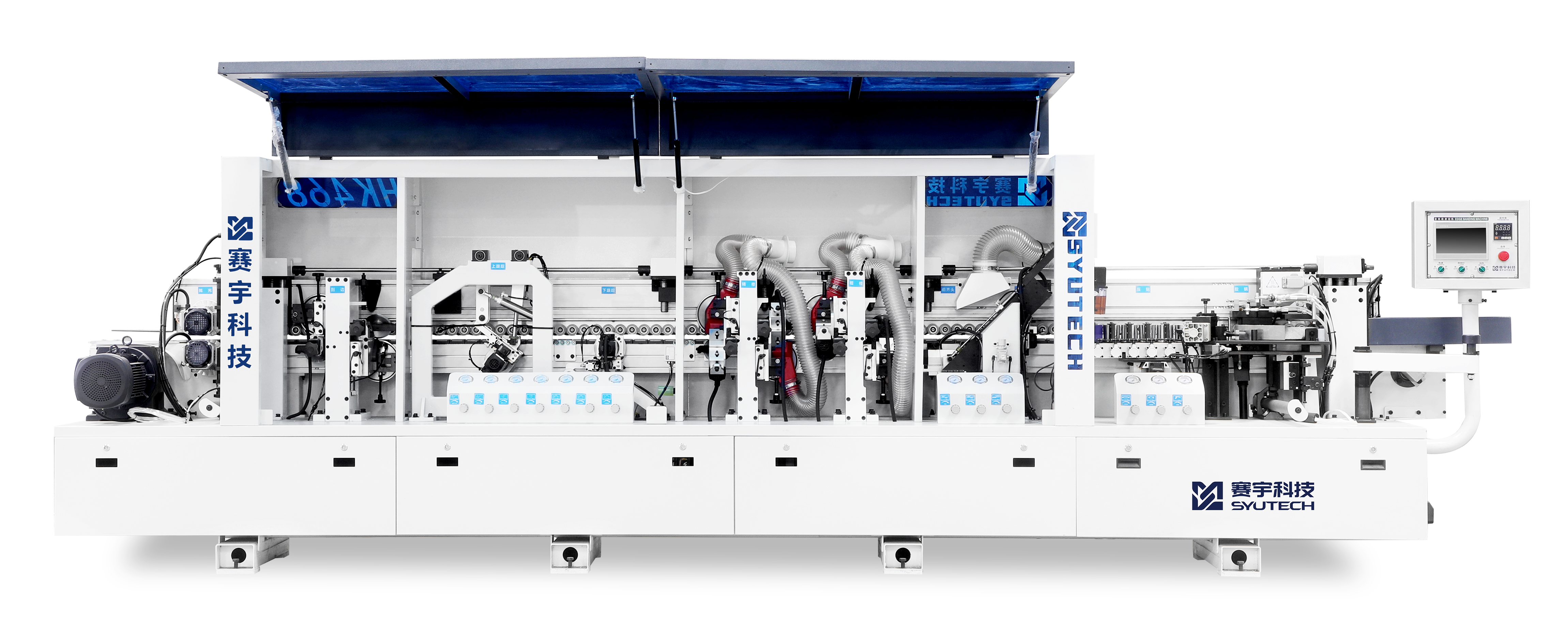

HK468 Edge Banding machine

Product Video

Parameters

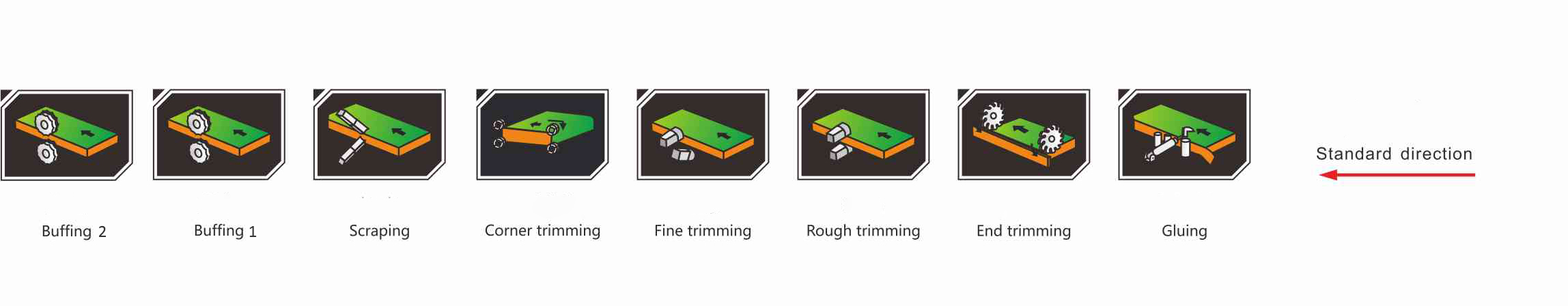

This automatic edge banding machine has 7 functions including Gluing, End trimming, Rough trimming, Fine trimming, scraping, Buffing1, Buffing1

| Model | HK468 |

| Panel length | Min.150mm(corner trimming45x200MM) |

| Panel width | Min.40mm |

| Edge band width | 10-60mm |

| Edge band thickness | 0.4-3mm |

| Feeding speed | 18-22-25m/min |

| Installed power | 10kw 380V50HZ |

| Pneumatic power | 0.7-0.9Mpa |

| Overall dimension | 6100*1000*1650mmmm |

Product Function

Huichuan Electric Control System

Stable and durable

Huichuan Electric Control System

Stable and durable

Multifunctional narrow board edge bander

Widely used in top cabinet sealing boards, closing boards, front and back braces for cabinets and floor cabinets, as well as corner lines for basic cabinets, it efficiently solves the edge sealing process at the end and easily handles narrow board edge sealing.

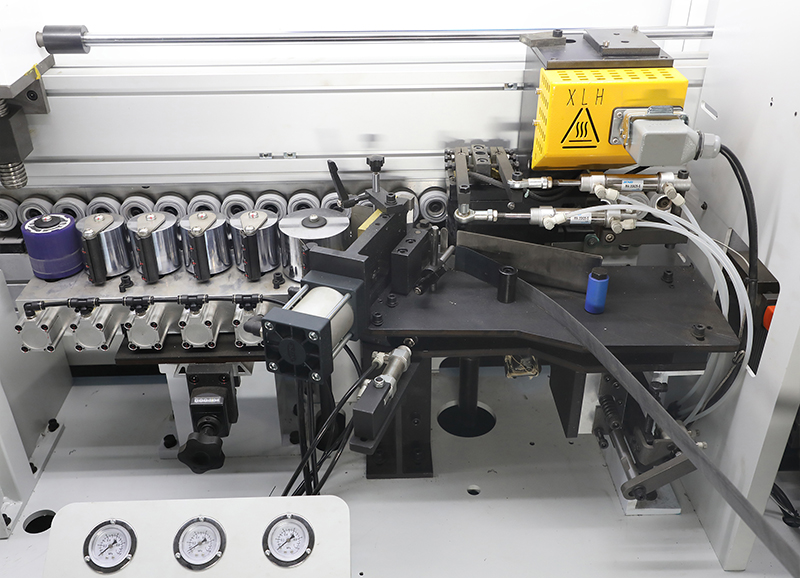

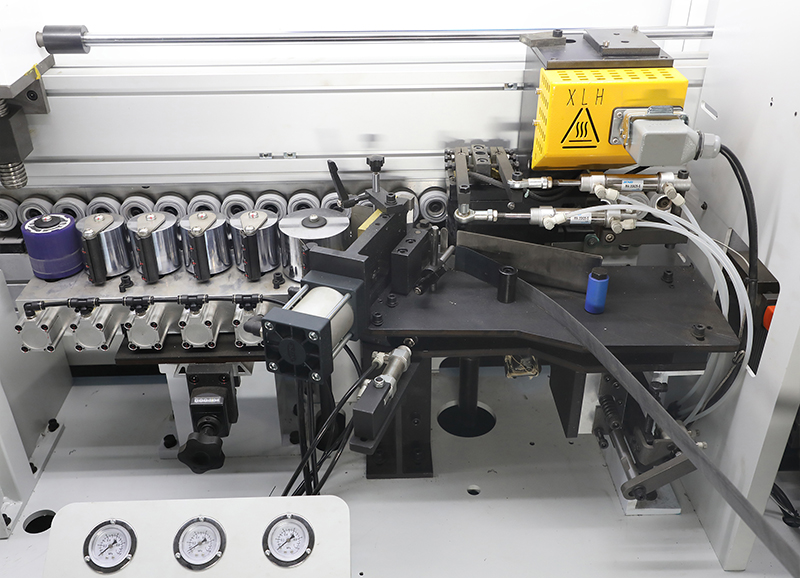

Upper gluing box

It is a standard pneumatic switch with a glue pot for gluing, paired with six rounds of pressing and pasting to improve edge sealing efficiency.

Upper gluing box

It is a standard pneumatic switch with a glue pot for gluing, paired with six rounds of pressing and pasting to improve edge sealing efficiency.

Haisen brand small roller chain block

The machine adopts Heisen small pressure wheels and chain blocks to ensure stable and durable edge sealing during plate transportation, ensuring the edge sealing effect.

Heavy Duty Rack

The machine has strong rigidity and deformation resistance, and after welding, the frame undergoes multiple processes such as aging, annealing, shot peening, and five axis machine tool processing to ensure processing accuracy and long-term stability.

Heavy Duty Rack

The machine has strong rigidity and deformation resistance, and after welding, the frame undergoes multiple processes such as aging, annealing, shot peening, and five axis machine tool processing to ensure processing accuracy and long-term stability.

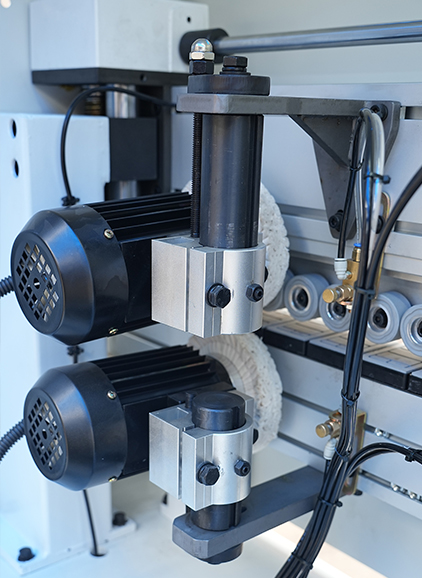

Syutech Patent Convenient Polishing

Two sets of polishing devices for better display of edge sealing effect,edge banding machine price

Samples