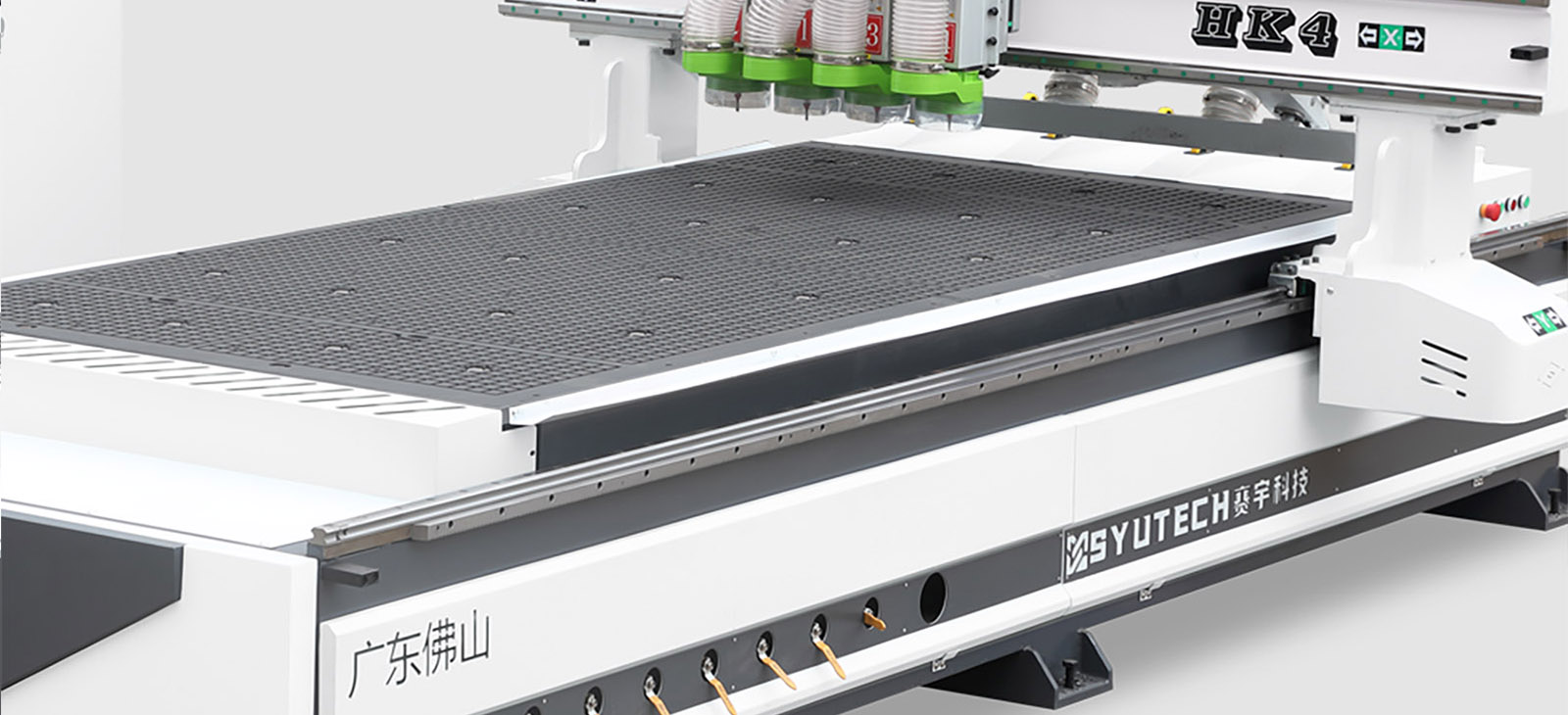

HK4 CNC router machine

Product Video

For the cnc router machine, we have two model, HK4 and HK6. HK6 can automatic change machine tools. HK 4 cannot automatic change machine tools.

Technical parameters

| X axis working arrange | 1300mm |

| Y axis working arrange | 2800mm |

| Z axis working arrange | 250mm |

| Max Air Move Speed | 80000mm/min |

| Axis rotation speed | 0-18000rpm |

| Axis motor power | 6kw*4pcs |

| Servo motor power | 1.5kw*4pcs |

| Inverter power | 7.5kw |

| Mode of X/Y axis drive | German 2-ground high-precision rack and pinion |

| Mode of Z axis drive | Taiwan High Precision Ball Screw |

| Effective machining speed | 10000-250000mm |

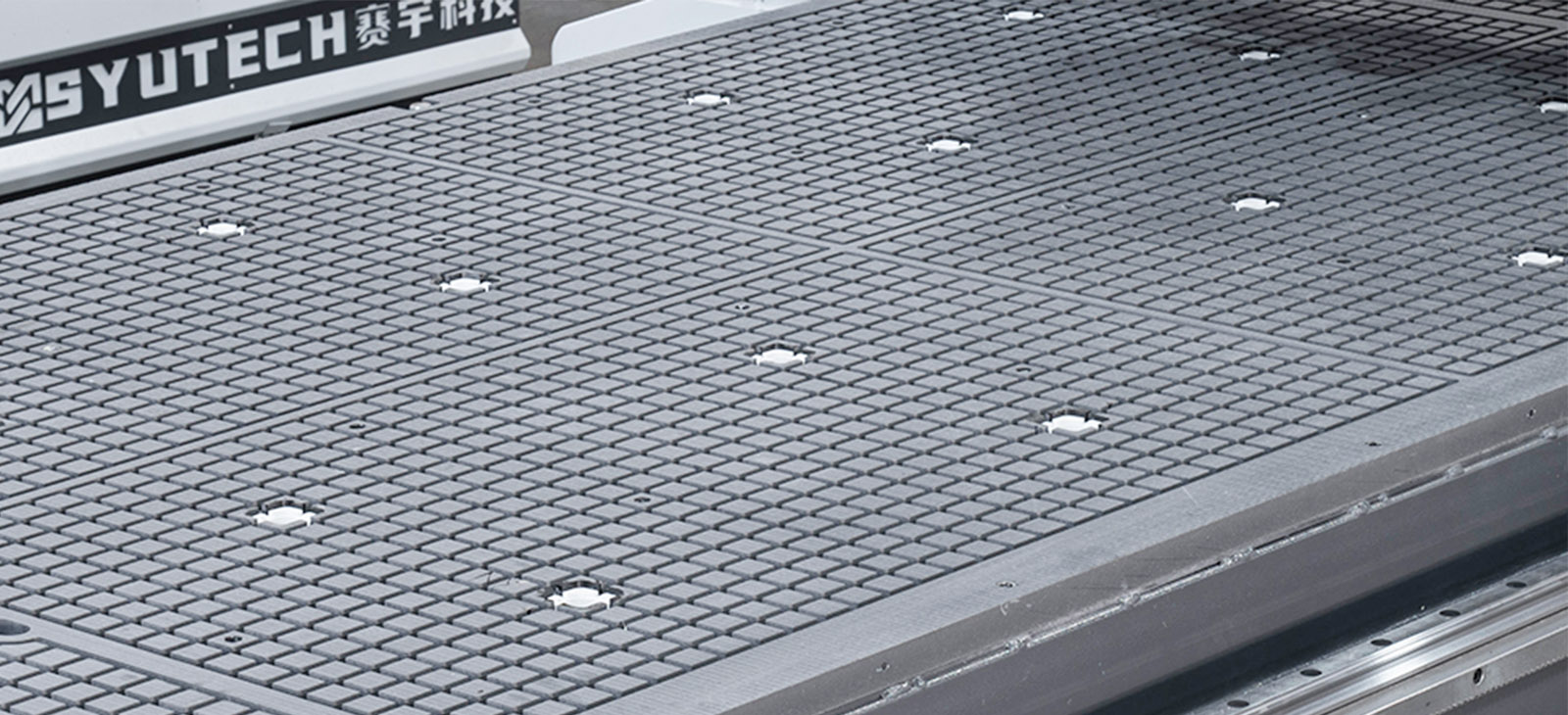

| Table structure | Vacuum adsorption of 24 holes in 7 regions |

| Machine body structure | heavy-duty rigid frame |

| reduction gears box | Japanese Nidec Gearbox |

| Positioning System | Automatic positioning |

| Machine size | 4300x2300x2500mm |

| Machine weight | 3000kg |

Heavy machine body

The overall frame undergoes annealing treatment to release stress, enhance ductility and toughness, and improve stability, making it less prone to deformation.

Vacuum adsorption table

The workbench has seven main sections that can be controlled independently. It is equipped with a high-power suction pump, which can be used for targeted patching and cutting of excess materials. It ensures that small boards can be processed without shifting.

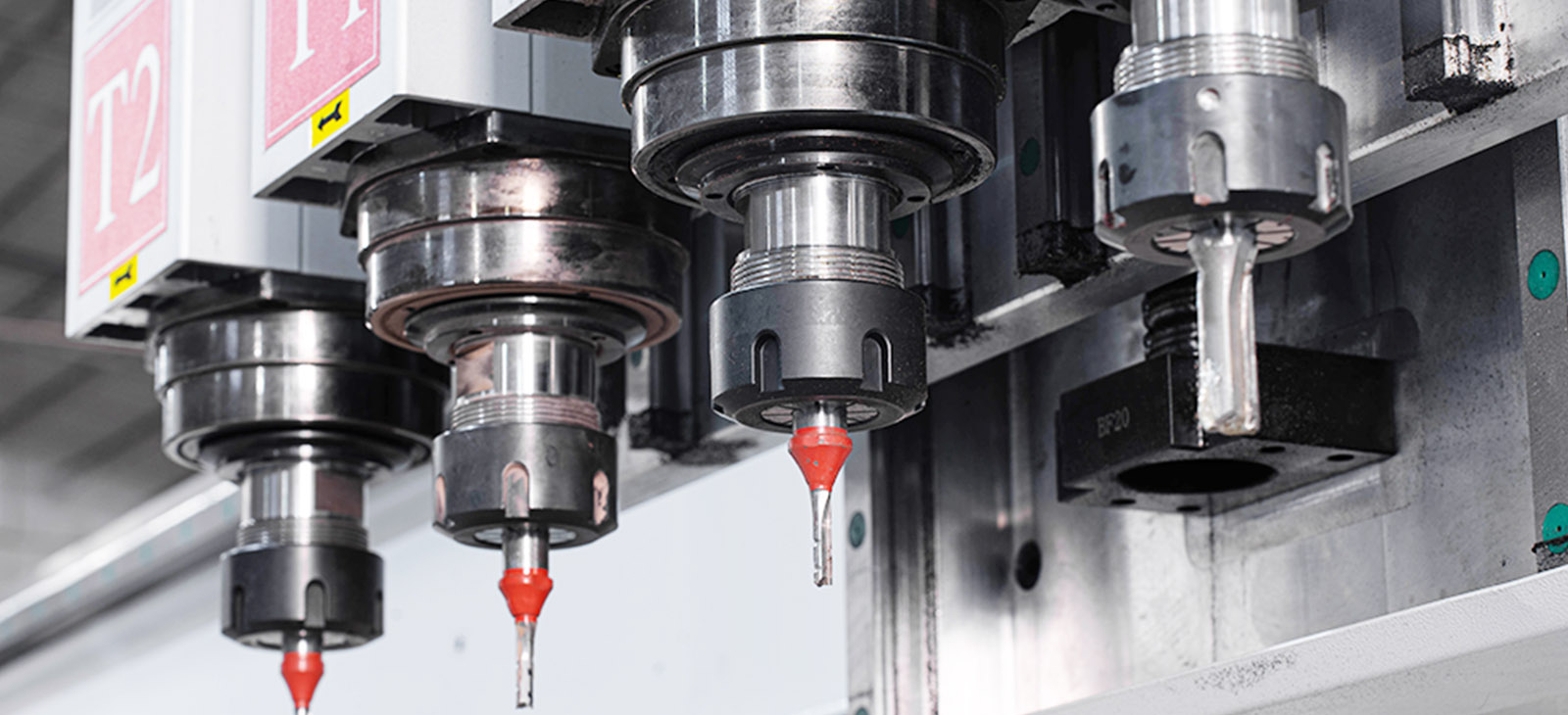

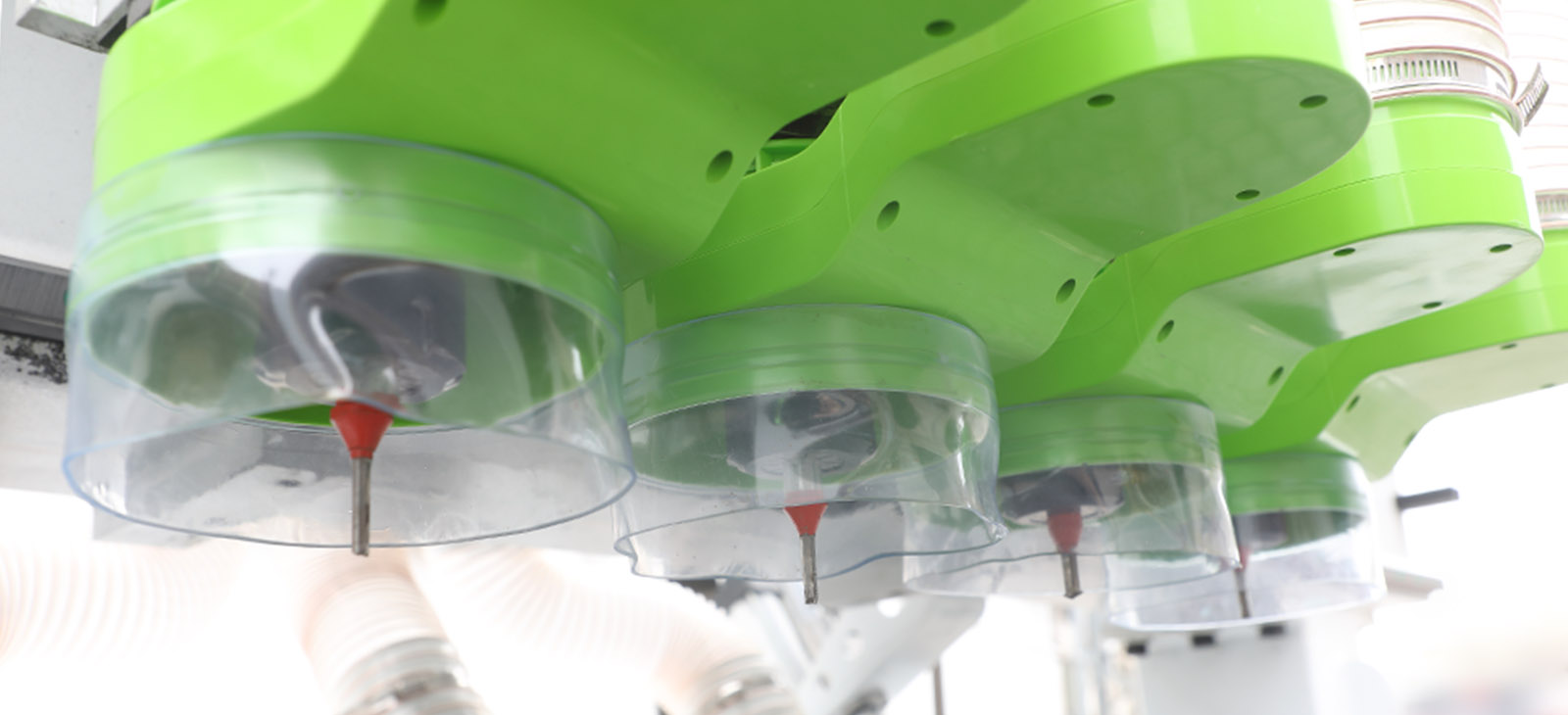

Ultra-fast tool change

The four-spindle change tools speed is fast, allowing for continuous processing. This saves time and effort, and improves production efficiency.

Inovance servo motor

Advanced precision intelligent compensation function

Reducing equipment failure rate

High-speed spindle motor

HQD6KW air-cooled high-speed spindle motor

High precision, low noise, and stability

Faster cutting and get smoother surface

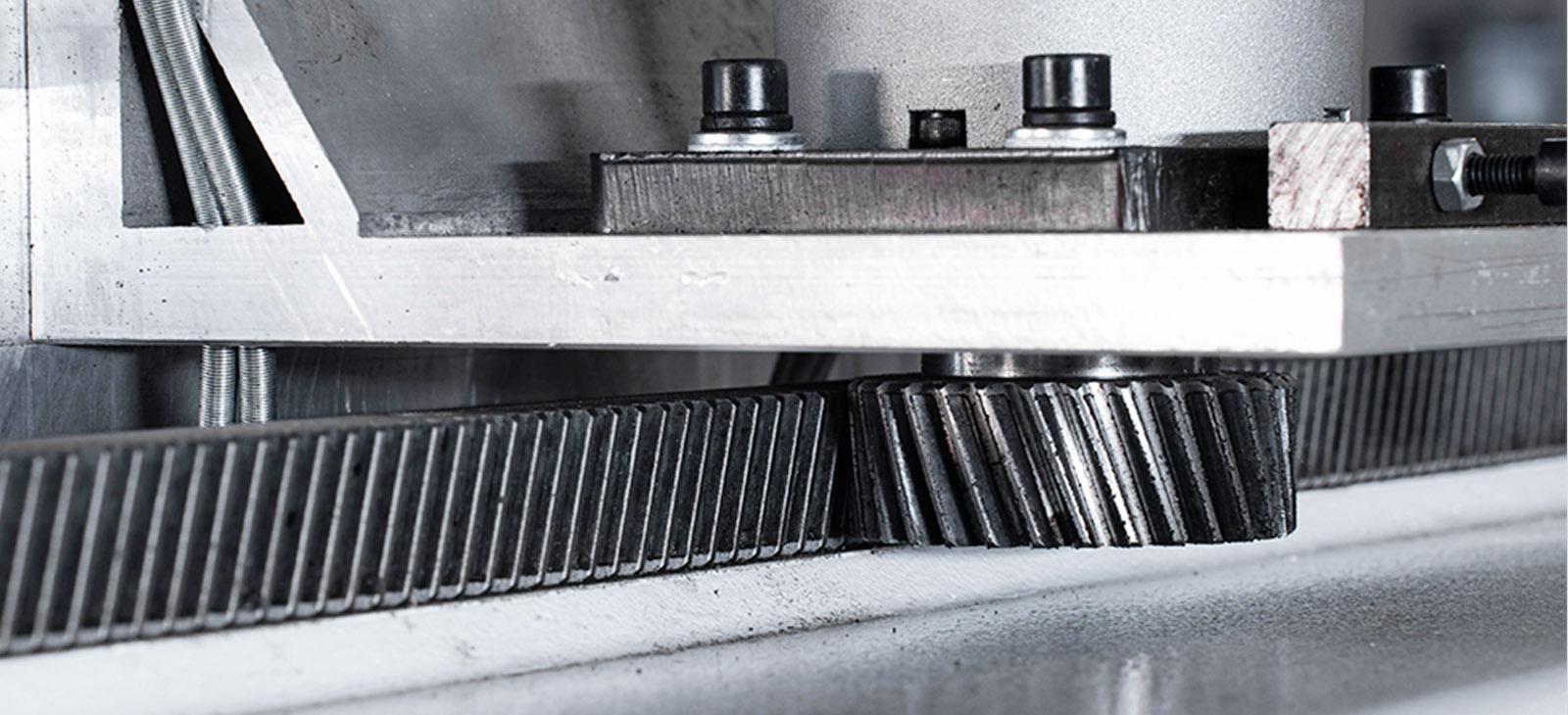

Japanese Nidec gearbox

Japanese Nidec gearbox, smooth operation

Low noise, wear-resistant, and more precise transmission

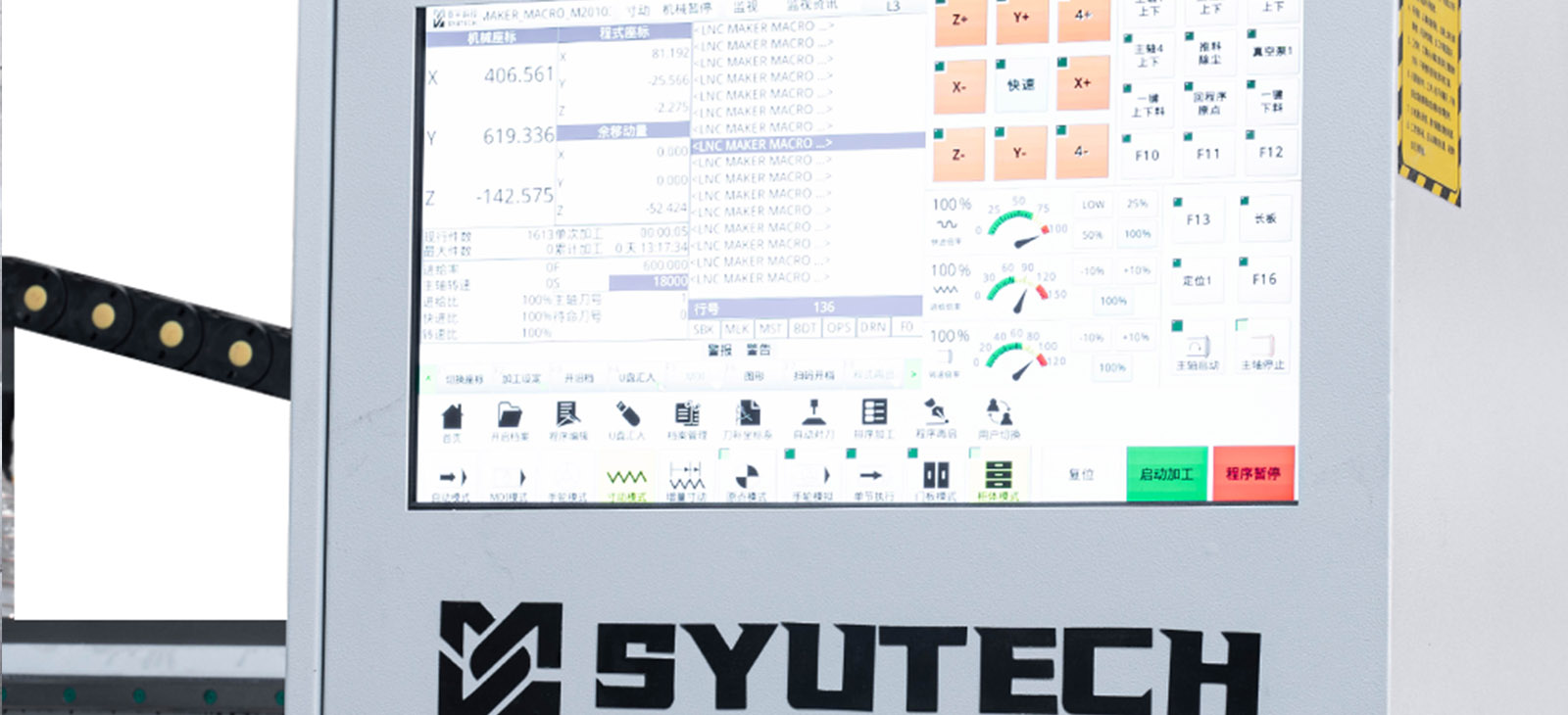

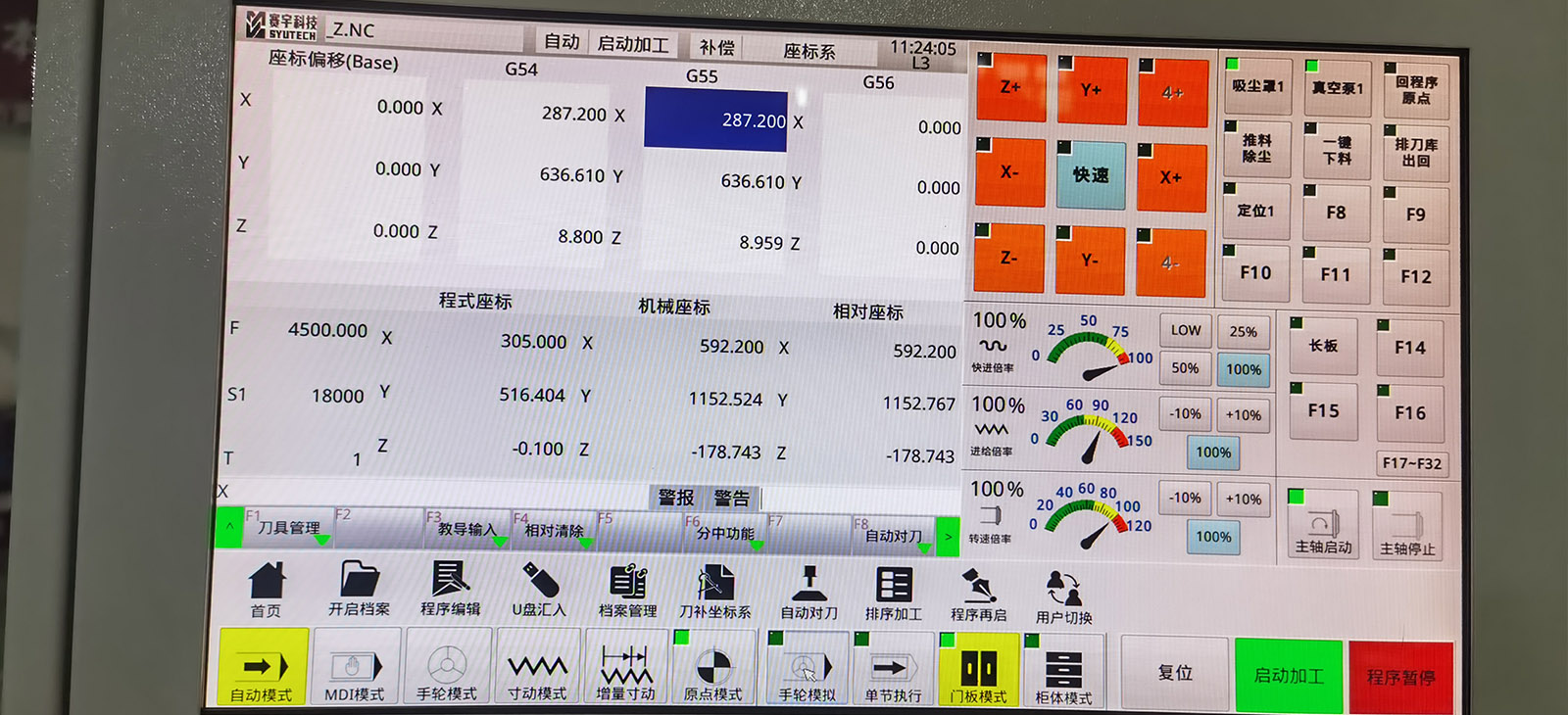

Yuanbao Control System

Taiwan Yuanbao Control System

Simple user interface, high stability

Used for high-end equipment or automatic production line.

Transmission accuracy

German high-precision rack + Taiwanese high-precision ball screw + Taiwanese linear guide

Low loss, long-lasting durability

Automatic Tool Setter

Up-and-down floating automatic tool setter

Accurate machining, reducing machine downtime

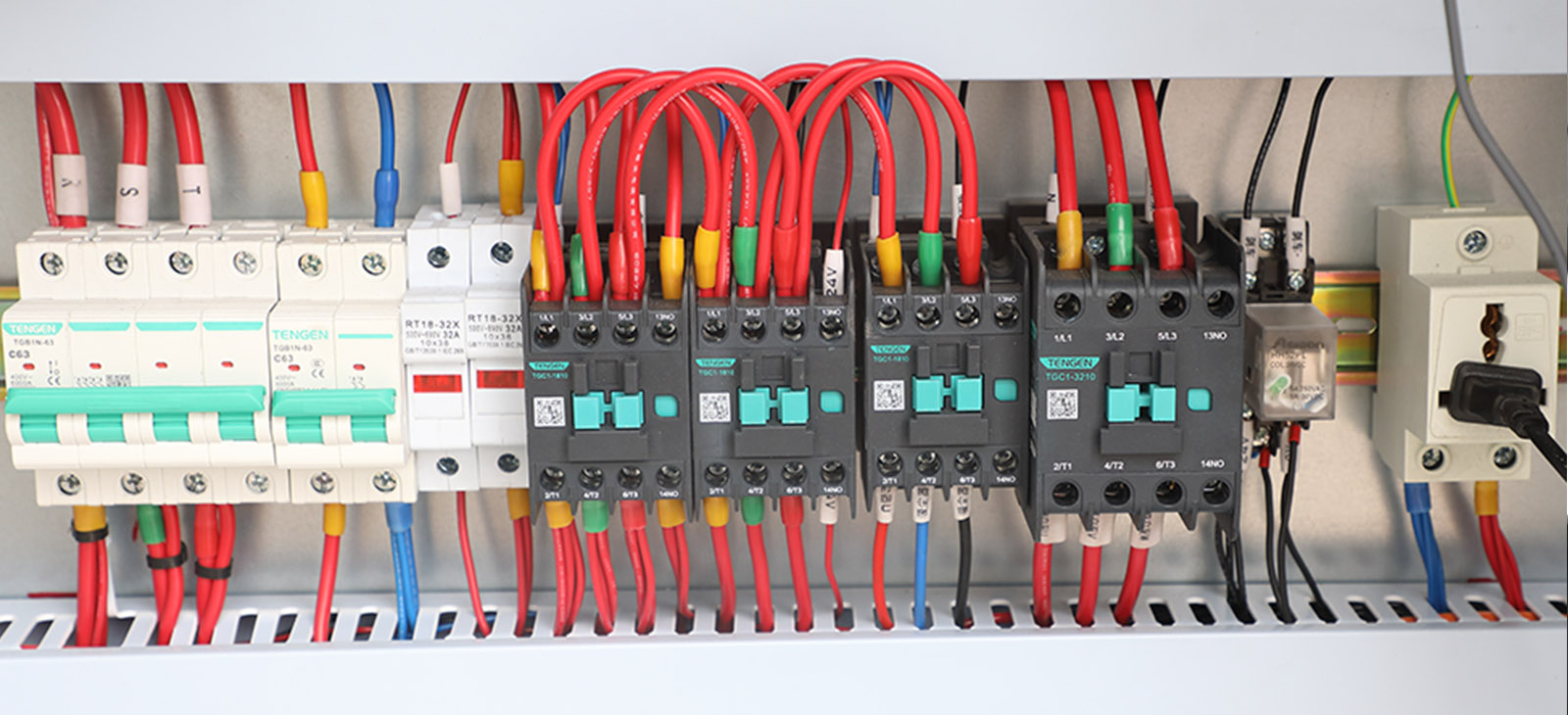

Precision electronic components

Inovance inverter, high efficiency and energy saving

Start-stop time of 3s, stable high-speed operation

France Schneider contactor

Flame retardant, safe and stable, high sensitivity

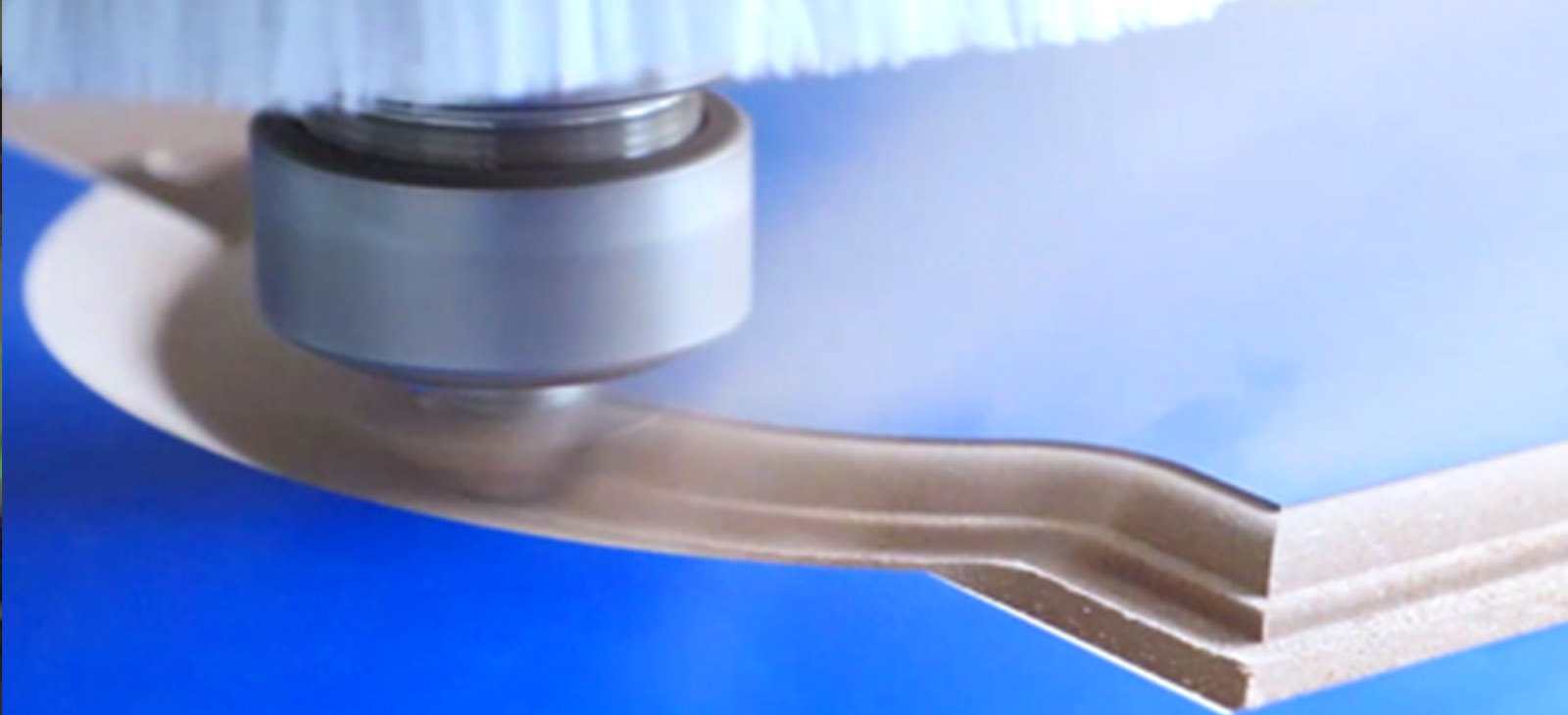

Auto cylinder feeding

Cylinder feeding, adding welding guide pillars

Assisted feeding with wheels for more stable material feeding

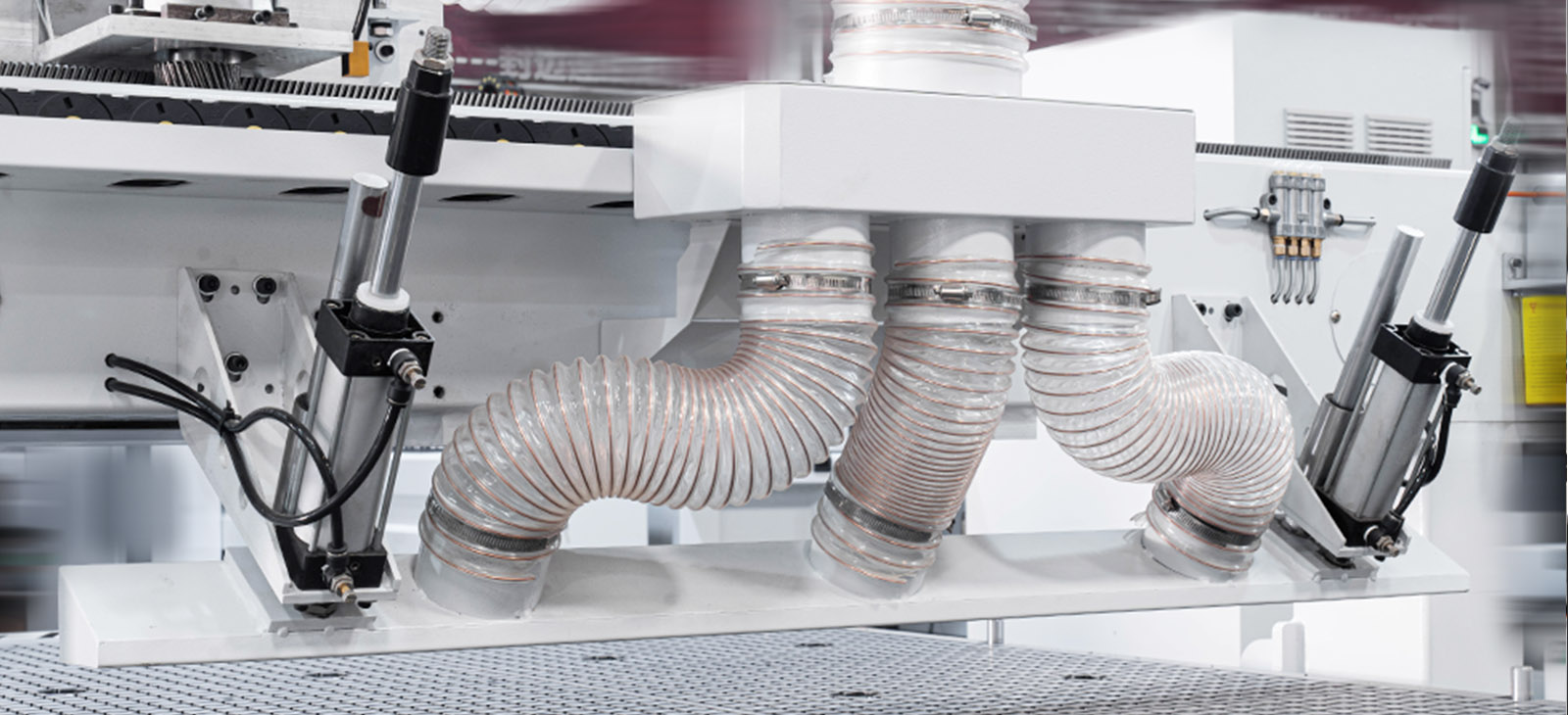

Dust removal device

X-axis spindle automatic partition full coverage dust suction method

Central dust collection + secondary dust removal

Ensure production environment.

Core Advantages

Intelligent Operation

Computer drawing, software comes with a large number of templates, intelligent operation is simple and convenient.

Optimize typesetting, improve the utilization rate of materials, reduce waste, and save costs.

Core Advantages

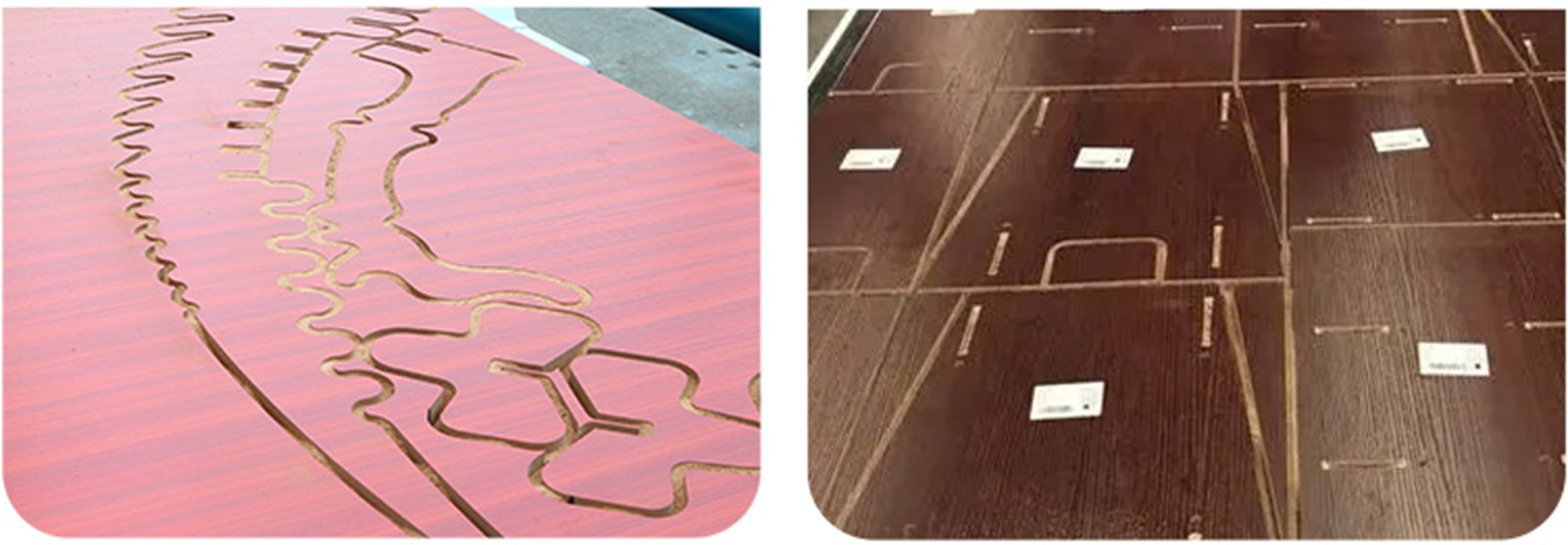

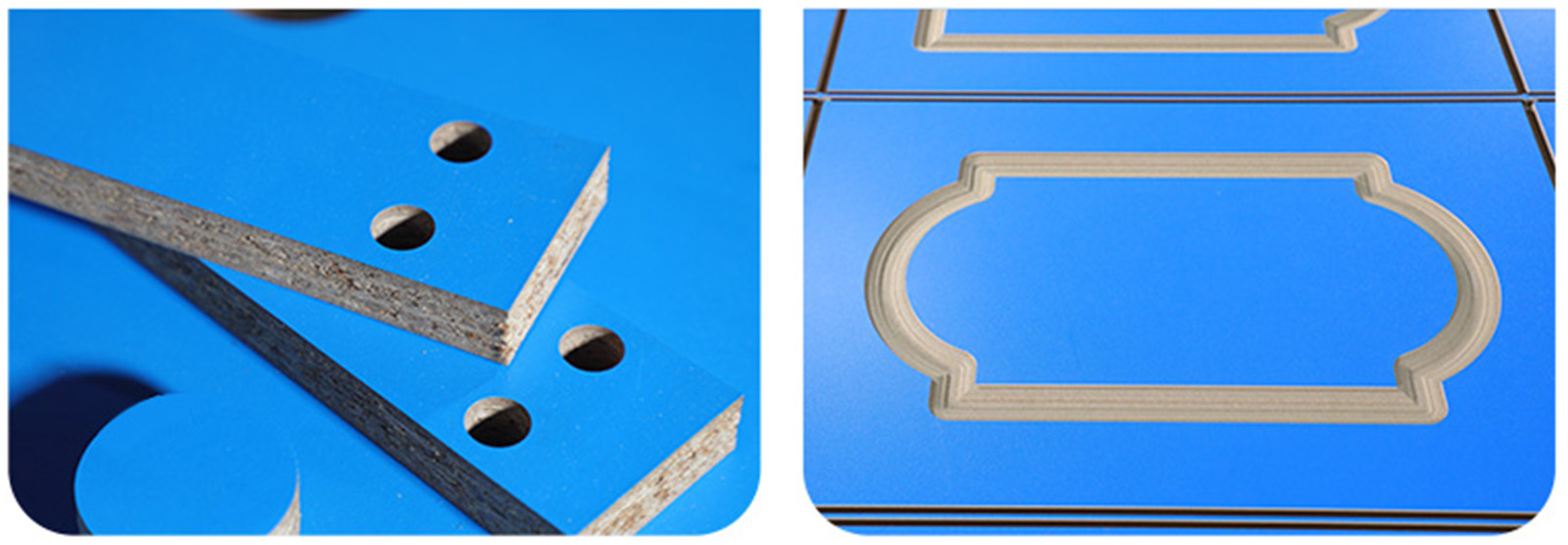

Widely used in various industries,

Can perform punching, slotting, material cutting, engraving, chamfering, and irregular shape cutting processing.

Application in different industries and fields, such as panel furniture, tables and chairs, wooden doors, cabinets, and sanitary ware.

Core Advantages

Efficient Processing Efficiency,

Improved recycling rate, time-saving, convenient, and suitable for all furniture processes.

The equipment has four main spindles, allowing for quick switching and high efficiency, making it capable of producing various cabinet or door panel designs.

Core Advantages

Dual Mode Switching

Between 48 feet and 49 feet with one click, fast and easy.

Cabinet mode is used for quick drilling, while door panel mode is used for corner shaping, meeting the needs of furniture production for end customers.

Core Advantages

Has strong compatibility

Can be integrated with any software on the market. It supports various furniture linking techniques, including hidden fittings, three-in-one fittings, laminates, wood-based easy fittings, and snap-on fittings.

Product Exhibition