HK330 Computer CNC panel saw

Product Video

Computer CNC panel saw HK330

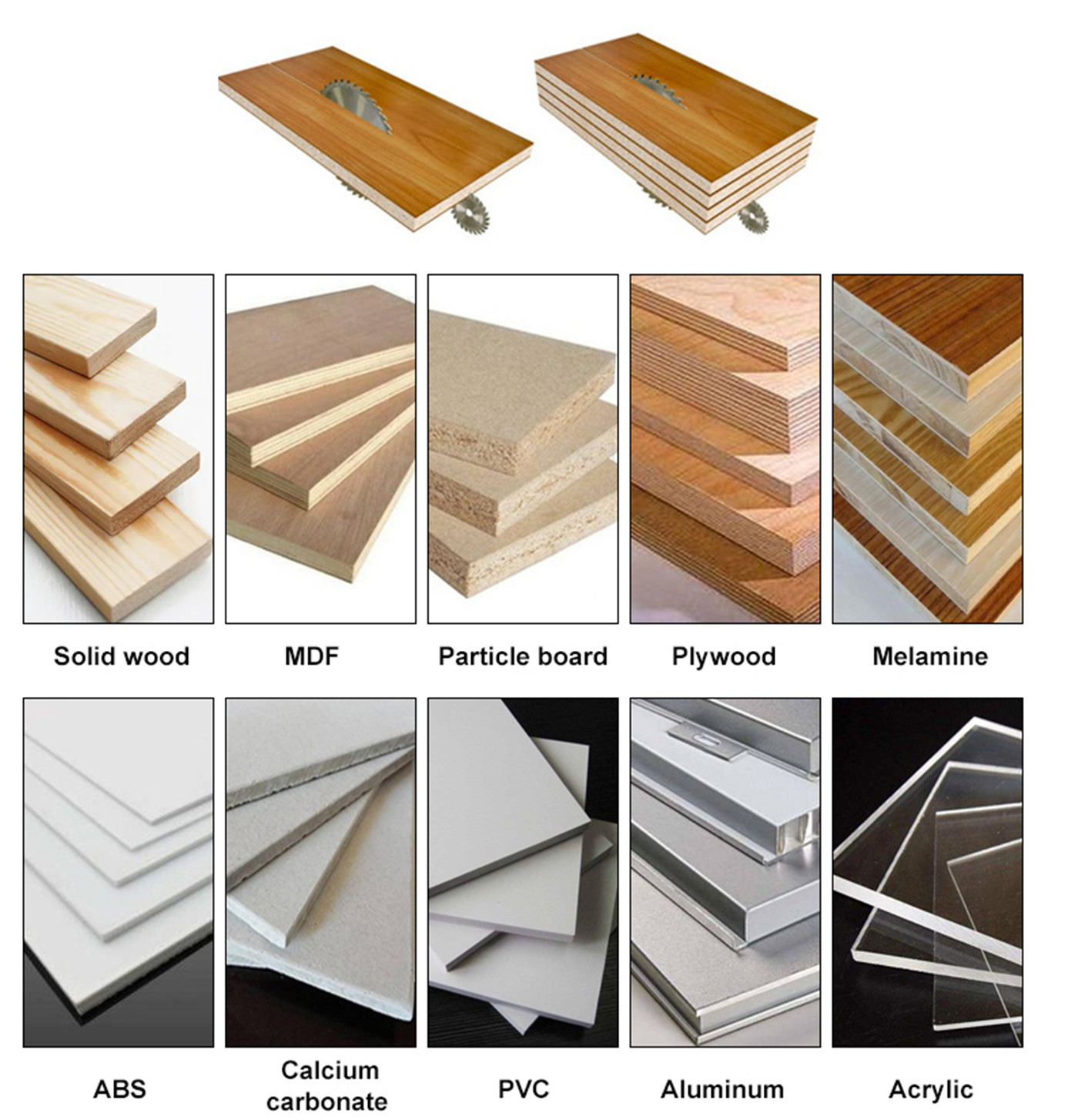

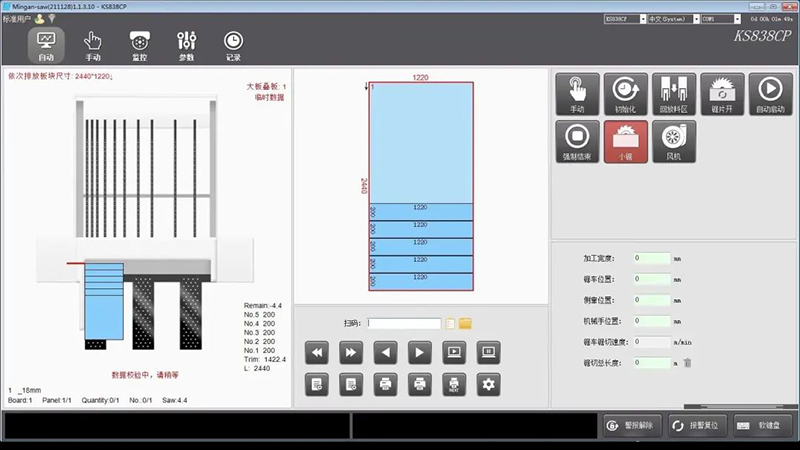

1. According to the input plate width, cut the required plate and quickly return to the original working state.

2. Cutting speed is controlled by frequency converter, which can overcome plates of different thickness and different materials.

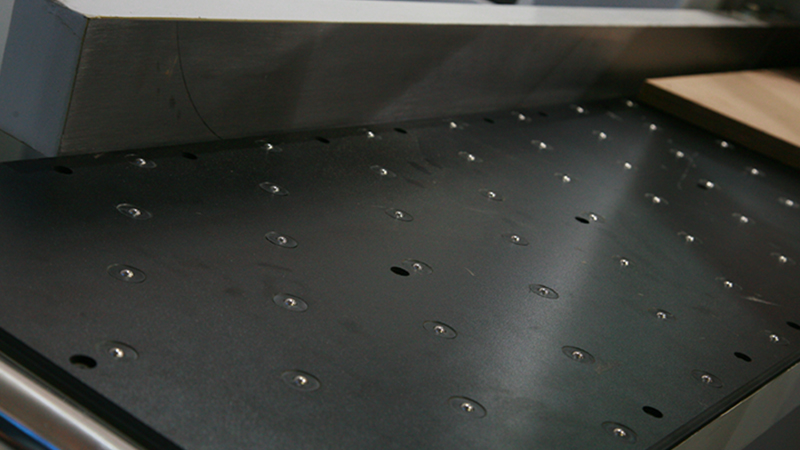

3. The feeding adopts pneumatic floating bead table, and the heavy plate material is easy to change. The robot automatically feeds, has low labor intensity and high production efficiency.

4. Use imported Delta servo motor to eliminate artificial error and improve dimensional accuracy.

Technical parameters

| HK330 | PARAMETER |

|

Maximum Cutting speed |

0-80m/min |

|

Max Carrier Maximum Speed |

100m/min |

|

Main Saw Motor Power |

16.5kw(optional18.5kw) |

|

Total Power |

26.5kw(optional28.5kw) |

|

Maximum Working Size |

3300L*3300W*100H(mm) Optional 120H(mm) |

|

Minimum Working Size |

34L*45W(mm) |

|

Overall Size |

5300L*5950W*1900H(mm) |

Meet the requirements of large plate processing, with a maximum sawing size of 2800 * 2800mm and a sawing thickness of 105mm, and a wider applicability

Servo mechanical clamp hand 11 single largest design mechanical clip

The robotic arm adopts high-precision worm gear reducer and feeding gear rack, with a cutting accuracy of ± 0.1mm

The worktable is made of Pneumatic floating platform.its very easy to move the panels

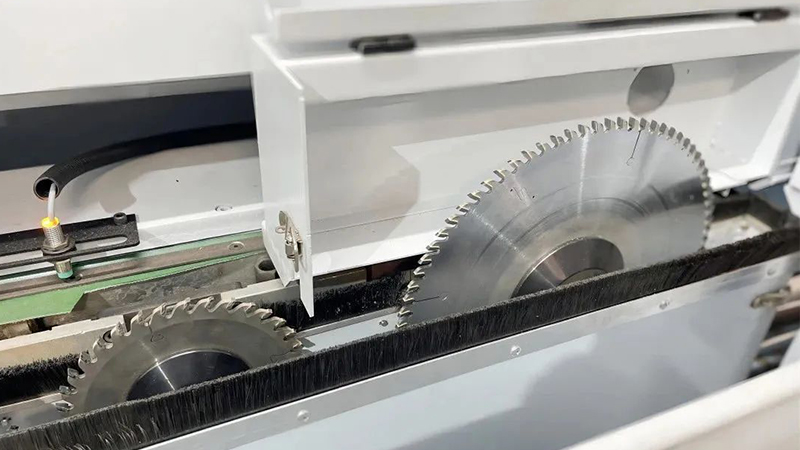

Scoring saw could be automatically switched according to the needs of sawing. Cooperate with the main saw for high-quality sawing

Optional optimization software for automatic optimization of material layout and

sawing Computer CNC panel saw

Sample