HK 465X-1 45° edge bandign macine

Technical Parameters

|

HK-465x-1 |

|||

|

Overall dimension |

5226*745*1625mm |

workpiece speed |

20-25m/min |

|

Thickness of edge band |

0.35-3mm |

Rated pressure |

0.6kg |

|

Operaing Weight |

T |

Convey motor power |

4KW |

|

Sheet width |

40mm |

total power |

12.2kw |

|

Sheet thickness |

9-60mm |

Minimum processing length |

150mm |

|

voltage |

380V 50HZ |

Forms of work |

full-automatic |

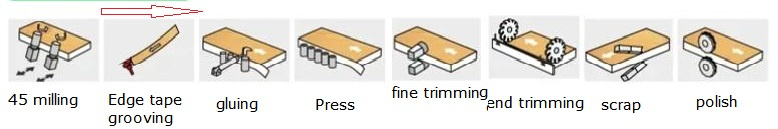

Machine characteristics

Incline pre-milling

Bevel edge milling type, 45° fixed pre-milling mechanism, sawing and crushing the edge of the cutting board, making the bevel edge sealing effect better.

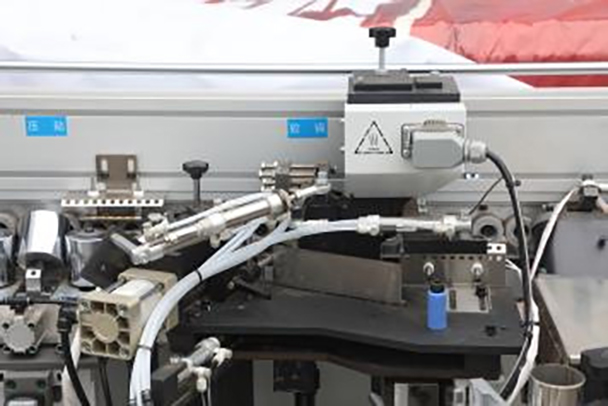

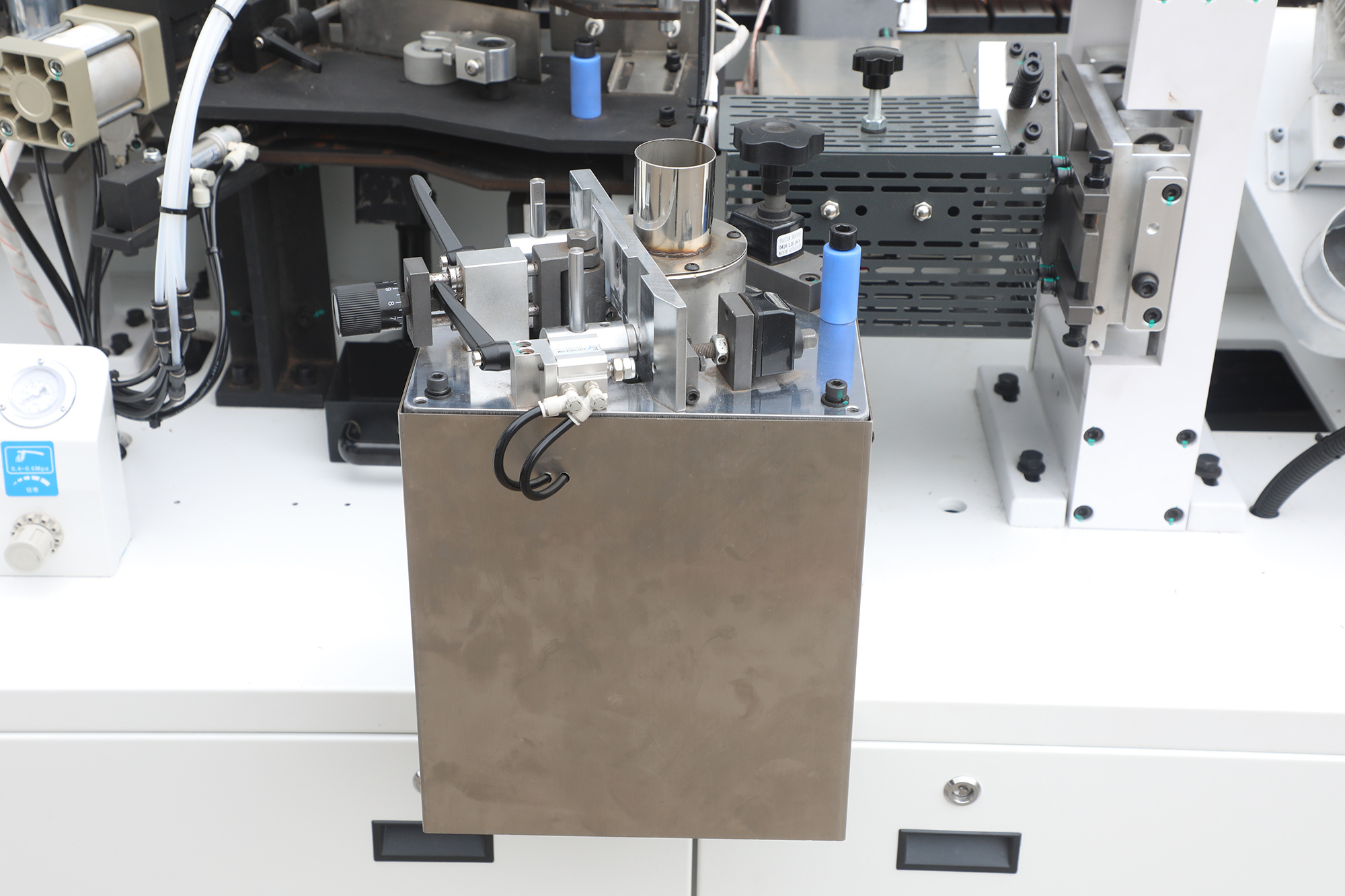

Incline gluing

The bevel edge glue coating and pressing mechanism can evenly apply glue to the bevel straight edge and seamlessly bond the bevel edge sealing.

Incline gluing

Use the glue pot to apply glue to the pneumatic switch. The glue is applied evenly and the glue line is fine.

Edge tape grooving

Notching grooves in the edge banding, notching and engraving the tape

Incline Press

Oblique straight pressing can ensure the perfect combination of the edge banding strip and the edge of the board, improving the beauty and durability of the board. This process is usually used in furniture manufacturing, decorative material processing, etc.

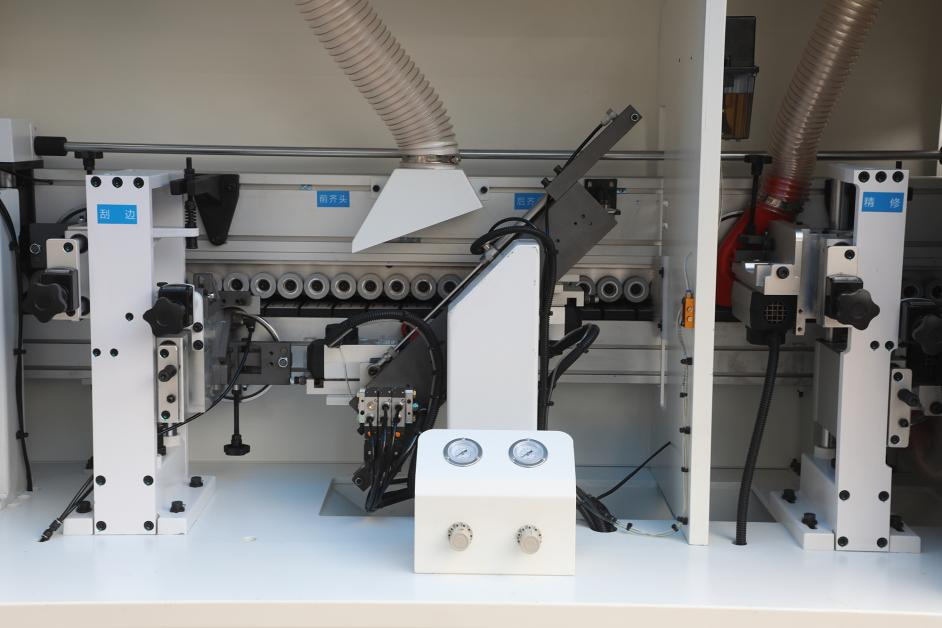

End Cutting

The independent flushing adopts a separate support base and guide rail to effectively avoid mutual vibrations affecting the flushing effect. The front and rear flushing are equipped with buffer devices to effectively avoid the impact of vibration caused by impact.

Scraping

Depending on the thickness of the edge banding, the edge scraper can be used flexibly for scraping. The scraping can be switched freely to make the edge banding arc smoother.

Polishing

The processed plate is cleaned by two polishing wheels rotating at high speed, making the edge-sealed section smoother and more beautiful, and allowing the polishing wheels to wear evenly.