HK-300 Cnc side drilling machine

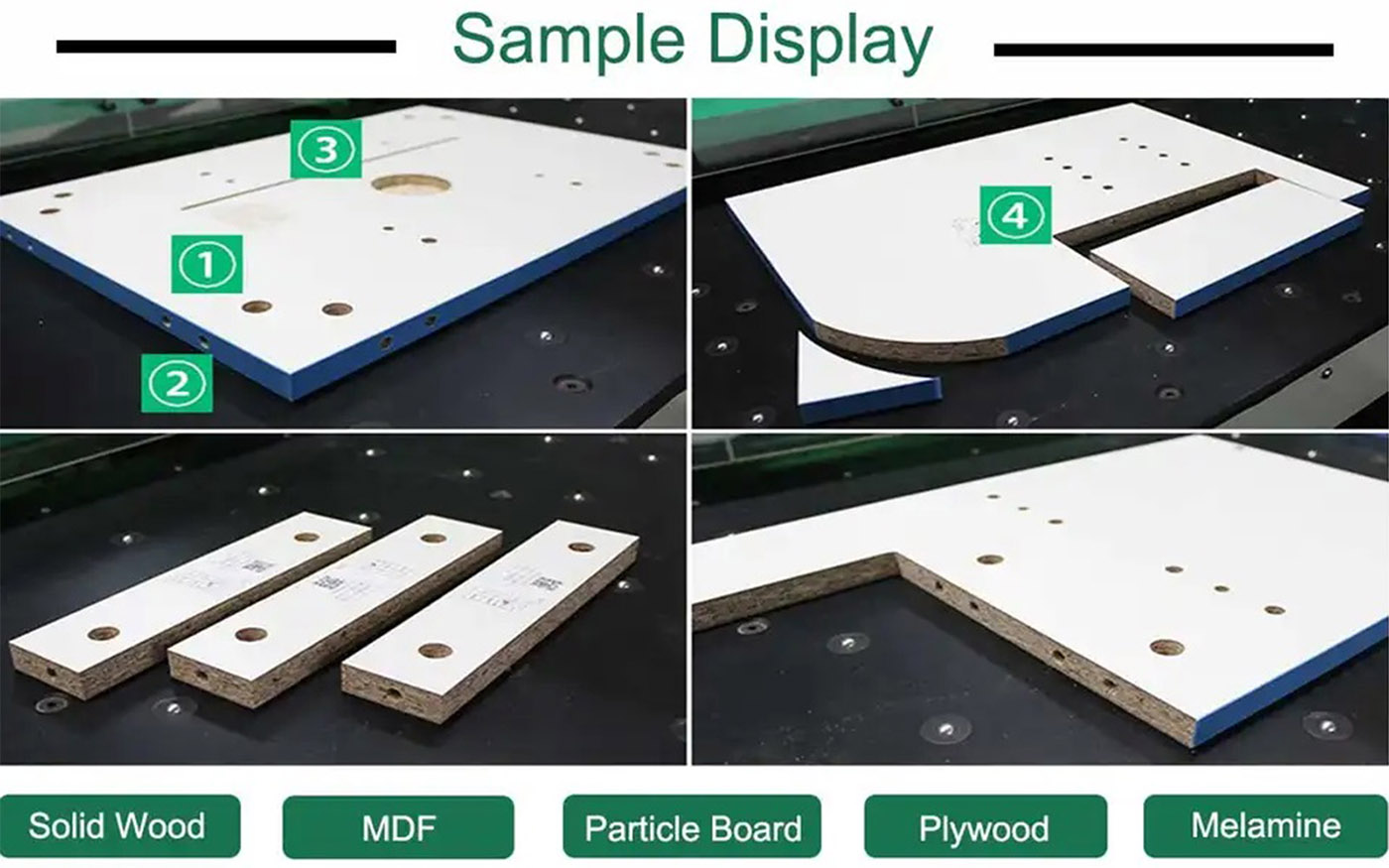

Horizontal side drilling is mainly used for wood panel hole drilling. This machine combines all the elements needed for a furniture manufacturer to design and machine custom cabinets, wardrobe, custom furniture and support products.It can do hole, grooving.

The furniture industry: cabinets, doors, panel, office furniture, doors and windows and chairs

Wood products: speakers, game cabinets, computer tables, sewing machines, musical instruments

The side drilling machine can use for all kind material: Acrylic, PVC, MDF, artificial stone, glass, plastic, and copper and aluminum and other soft metal sheet.

1. The CNC side hole drill machine is an economical and practical panel furniture horizontal hole making equipment, it can composed economical plate furniture production line with cutting machine

2. It can replace the traditional table saw and row drilling. Its biggest advantage is that it can scan the side holes directly, cast off the traditional processing methods depend on the chief Boring. 3.The machine is mainly used to solve the problem that the CNC drilling machine can not drills the side holes.Easy to operate,truly make intelligent production with high precision and speed. 4.CNC horizontal single row drilling machine can drill horizontal holes through automatic induction vertical hole. High drilling speed, high efficiency, realize 0 error processing.

Machine parameter

| X axis working size | 2800mm |

| Y axis working size | 50mm |

| Z axis working size | 50mm |

| Servo motor | 750w*3pcs |

| Spindle : | HQD 3.5kw |

| Pressure cylinder | 8 pcs |

| Machine size | 3600*1200*1400mm |

| Working table size | 3000*100 |

| Machine weight | 500kg |