Automatic 45 degree sliding table panel saw

Product Video

Automatic 45 degree sliding table panel saw

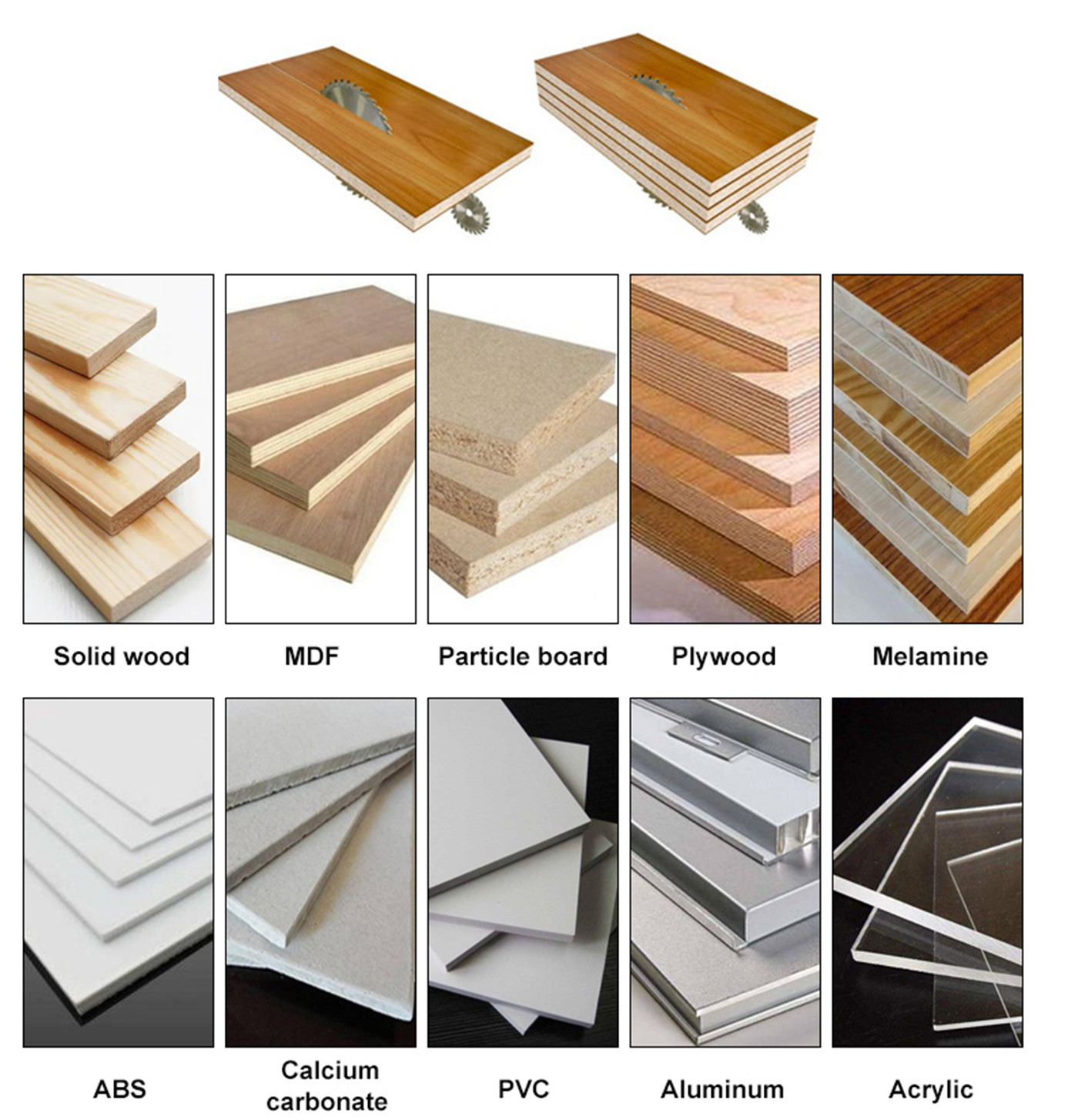

Automatic panel saw is an efficient and precise wood processing equipment, mainly used for cutting boards such as plywood, density board, particle board, etc. It is widely used in furniture manufacturing, architectural decoration, wood products processing and other industries.

Main features

High degree of automation: equipped with CNC system, automatically complete cutting tasks, reduce manual intervention.

High precision: servo motor and precision guide rail are used to ensure accurate cutting size.

High efficiency: multiple pieces can be cut at the same time, greatly improving production efficiency.

Easy operation: touch screen interface, parameter setting and operation are simple and easy to learn.

High safety: equipped with protective devices and emergency stop function to ensure safe operation.

Product specifications

| Model | MJ6132-C45 |

| Sawing angle | 45° and 90° |

| Max cutting length | 3200mm |

| Max cutting thickness | 80mm |

| Main saw blade size | Φ300mm |

| Scoring saw blade size | Φ120mm |

| Main saw shaft speed | 4000/6000rpm |

| Scoring saw shaft speed | 9000r/min |

| Sawing speed | 0-120m/ min |

| Lifting method | ATC(Electric lifting) |

| Swing angle method | Electric swing angle) |

| CNC positioning dimension | 1300mm |

| Total power | 6.6kw |

| Servo motor | 0.4kw |

| Dust outlet | Φ100× 1 |

| Weight | 750kg |

| Dimensions | 3400×3100×1600mm |

Product detail

1.Interior structure:The motor adopts all copper wire motor, durable. Large and small double motor, large motor 5.5KW, small motor 1.1kw, strong power, long service life.

2.European bench:Euroblock aluminum alloy double layer 390CM wide large push table, made of high strength extrusion aluminum alloy, high strength, no deformation, push table surface after oxidation treatment, beautiful wear resistant.

3.Control panel:The 10-inch control screen, the interface is simple and easy to operate.

Saw blade ( CNC up and down):There are two saw blades, saw blade automatic lift ,can be entered the size on the control panel

5.Saw blade ( Tilting angle):electric tilting Angle, press the button Angle adjustment can be displayed on the digital developer

6.CNC

positioning ruler:Working Length :1300mm

CNC positioning ruler(rip fence)

7.rack:The heavier frame improves the stability of the equipment, reduces the error brought by various vibration, ensures the cutting precision and has a longer service life. High quality baking paint,overall beautiful.

8.guiding rule:Standard with large scale,

smooth surface without burr,

stable without displacement,

sawing more accurate. The mold base adopts the new internal

stability structure to ensure the stability of the backer, and the push is smoother.

9.oil pump:Supply oil to guide rail, Make the main saw linear guide more durable, more smooth.

10.Round rod guide:The pushing platform adopts chromium-plated round rod structure. Compared with the previous linear ball guide rail, it has stronger wear resistance, longer service life, higher positioning accuracy, and easier to push

Sample